Electronics Industry Expertise

15+ years serving electronics manufacturers worldwide with precision enclosures, thermal solutions, and EMI shielding components.

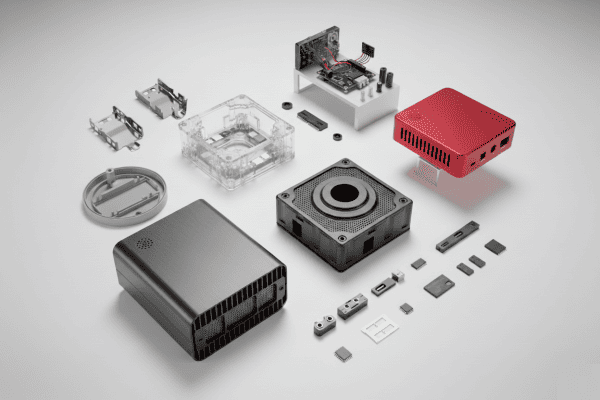

Electronics Specialization

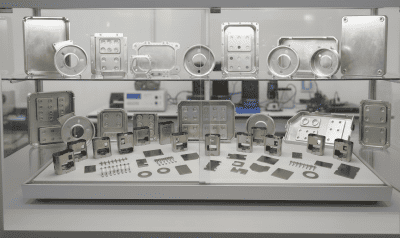

PCB enclosures, heat sinks, and device chassis with precise tolerances.

Rapid Prototyping

5-7 day turnaround with full DFM analysis and design optimization.

Thermal Management

Custom heat sinks and thermal interface solutions for heat dissipation.

EMI/RFI Shielding

Conductive coatings and shielded enclosures for EMC compliance.

Scalable Production

From 1 prototype to 100,000+ units with consistent quality control.

Global Compliance

ISO 9001:2015 certified with RoHS, REACH, and UL compliance.

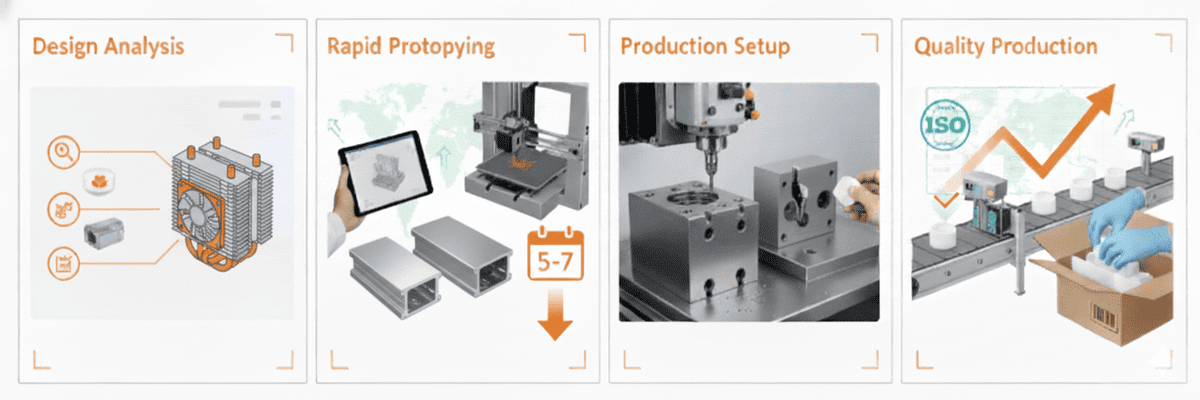

From Design to Production

Streamlined manufacturing process ensuring precision and quality at every step.

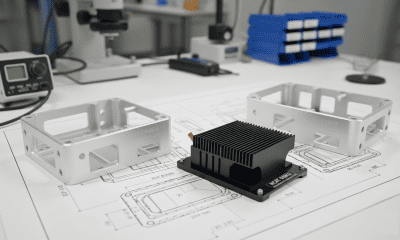

Design Analysis

CAD review and manufacturability analysis with material recommendations and tolerance optimization.

Rapid Prototyping

Quick prototypes for validation and testing with first article inspection and approval process.

Production Setup

Custom tooling design and manufacturing with comprehensive quality control setup and testing.

Quality Production

ISO certified manufacturing with full inspection reports, packaging, and global shipping coordination.

Trusted by Electronics Leaders

See how we've helped electronics manufacturers achieve their production goals with precision enclosures and components.

"Xu Feng delivered custom aluminum enclosures for our IoT devices with perfect thermal management. The EMI shielding exceeded our requirements and the 6-day prototype turnaround was incredible."

"From prototype to 50,000 units, Xu Feng scaled with us seamlessly. Their injection molded housings for our medical devices meet all regulatory requirements with consistent quality."

"The precision CNC machined robot chassis components have been flawless. Xu Feng's engineering team provided excellent DFM feedback that improved our design and reduced costs."

Electronics Manufacturing Knowledge Hub

Expert insights on electronics enclosure design, manufacturing techniques, and industry best practices.

EMI/RFI Shielding Design Best Practices for Electronics Enclosures

Learn how to design effective electromagnetic interference shielding into your electronics enclosures for regulatory compliance.

Read More

Advanced Thermal Management Solutions for High-Power Electronics

Explore heat sink design, thermal interface materials, and cooling strategies for electronics operating in demanding environments.

Read More

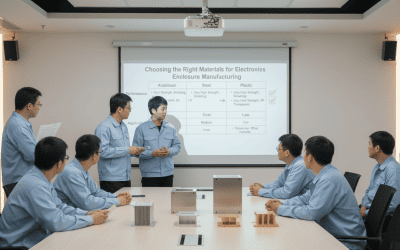

Choosing the Right Materials for Electronics Enclosure Manufacturing

Compare aluminum, steel, and plastic options for electronics housings based on performance, cost, and application requirements.

Read More

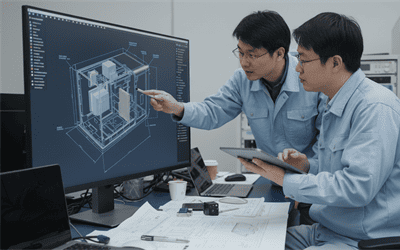

Expert Guidance on

Electronics Parts Development

From concept to production, our engineering team provides comprehensive support for electronics enclosures, heat sinks, connectors, and precision components with thermal management expertise.

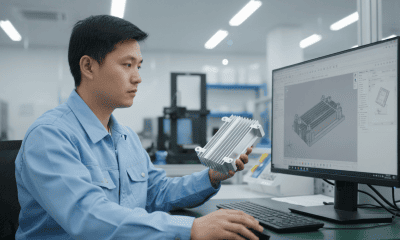

DFM & Design Optimization

Comprehensive design for manufacturability analysis focusing on electronics requirements, thermal dissipation, and assembly efficiency.

- Thermal management optimization

- EMI/RFI shielding considerations

- Cost reduction strategies

Process Selection & Optimization

Optimal manufacturing process recommendation based on volume, complexity, and performance requirements.

- CNC machining for precision housings

- Injection molding for volume production

- Sheet metal for enclosures & brackets

Material Selection Expertise

Strategic material recommendations based on electrical properties, thermal conductivity, and environmental requirements.

- Aluminum alloys for heat dissipation

- Engineering plastics (PC, ABS, Nylon)

- Conductive & insulating materials

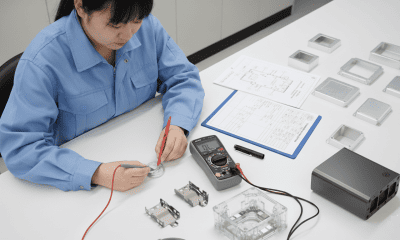

Quality Assurance & Testing

Comprehensive quality control with electronics-specific testing protocols and certification support.

- Dimensional inspection (CMM)

- Surface finish verification

- IP rating & environmental testing

Let's Discuss Your Electronics Project

Schedule a technical consultation with our electronics manufacturing specialists to optimize your design and production strategy.