Custom

Medical Parts

Manufacturing

From surgical instruments to diagnostic equipment, Xu Feng delivers ISO 13485 certified manufacturing for critical medical components with unmatched precision and regulatory compliance.

Regulatory Compliant Medical Solutions

ISO 13485 certified facilities delivering critical medical components with full traceability, validation, and regulatory compliance from prototype to production.

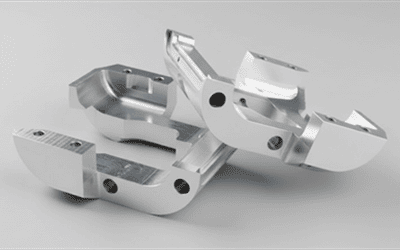

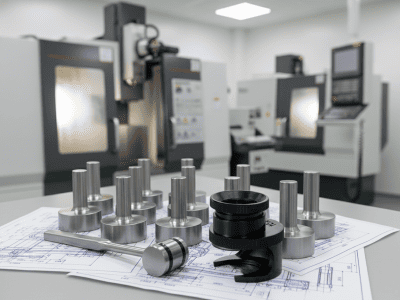

Surgical Instruments

Precision machined surgical tools with biocompatible materials and mirror finish requirements.

- Titanium, 316L Stainless Steel

- Ra 0.4μm Surface Finish

- Full Material Traceability

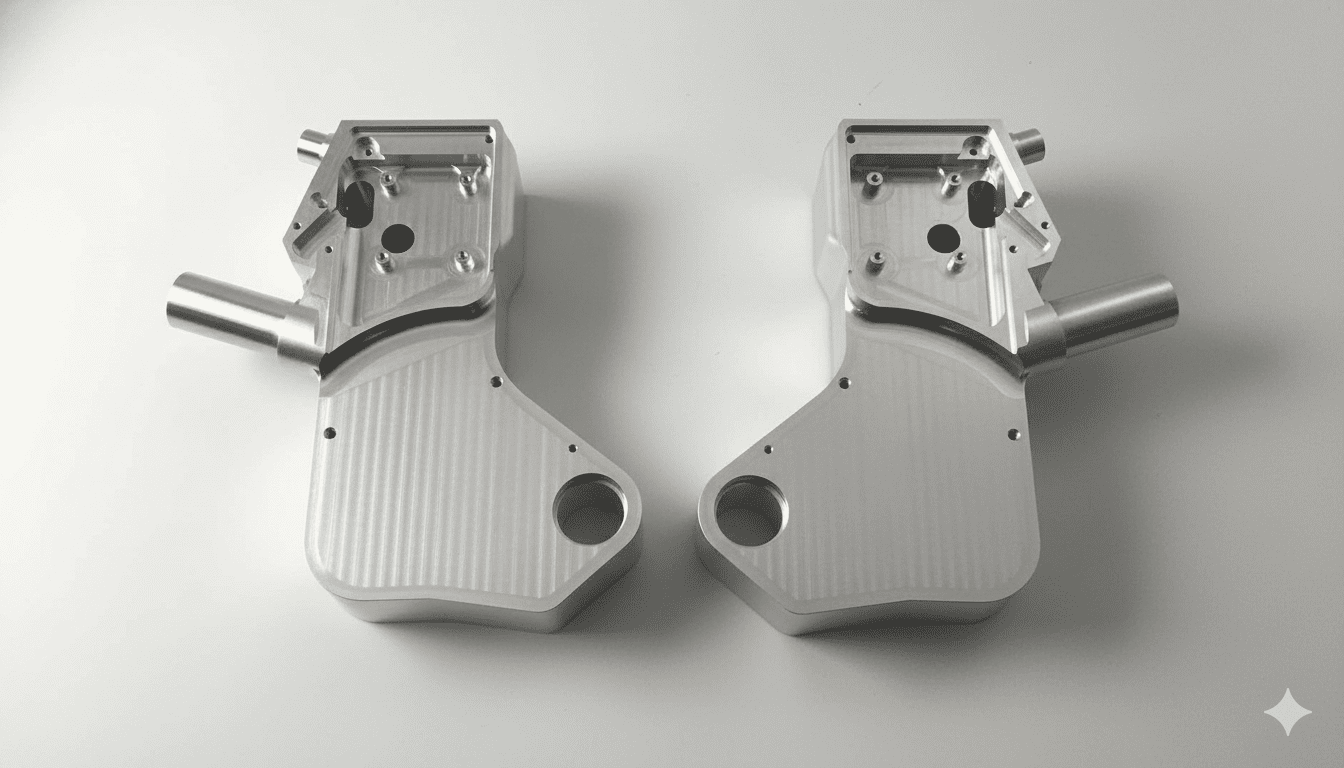

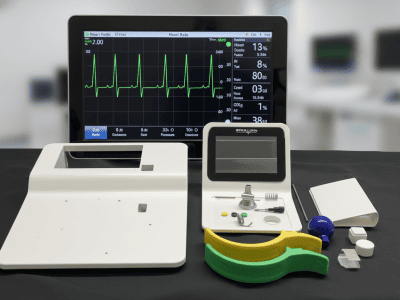

Monitoring Equipment

Precision housings and components for medical imaging and monitoring device applications.

- EMI/RFI Shielding

- Medical Grade Plastics

- IP65/IP67 Sealing

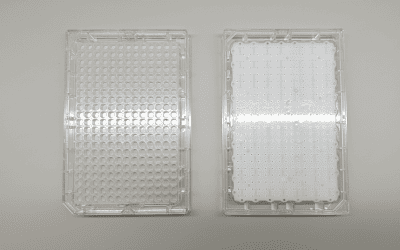

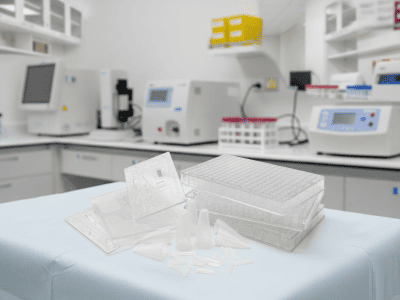

Diagnostic Consumables

Precision injection molding for laboratory testing and diagnostic equipment components.

- 96-Well Plates & Microplates

- Microfluidic Chips

- Centrifuge Tubes & Tips

Medical Device Manufacturing Process

From design validation to final inspection, our ISO 13485 certified process ensures every medical component meets the highest standards.

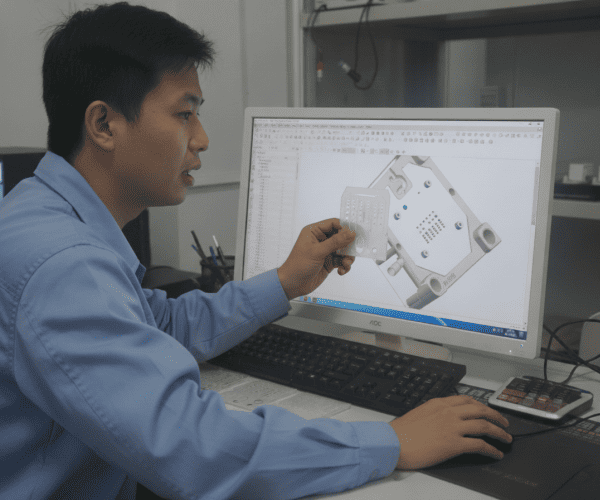

Design Review

Comprehensive DFM analysis with biocompatibility assessment and regulatory compliance review.

Material Selection

Medical-grade materials with full traceability and a material certification report.

Precision Manufacturing

Clean room environment with validated processes and real-time quality monitoring.

Quality Assurance

100% inspection with ISO process, sterilization validation, and complete documentation.

Full Production Support Team

Business Team Support

- Project management & scheduling

- Global logistics coordination

Engineering Team Excellence

- DFM analysis & design optimization

- Material & process consultation

Production Team Quality

- ISO 9001 & 13485 certified processes

- CMM inspection & quality reports

Case Study: Microfluidic Plate Prototyping

Project Overview

A Canadian biotechnology company needed rapid prototyping of microfluidic plates for their diagnostic testing platform. The project required ultra-precise micro-channels with multiple design variations and material testing across different polymer substrates.

Technical Challenge

- 40μm micro-channel precision

- Multiple channel patterns required

- Multi-material compatibility testing

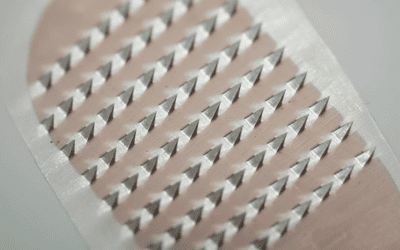

Our Solution

- Precision etching technology

- Interchangeable insert system

- PP, PC, COC, PCTG testing

Results Achieved

"Xu Feng's etching technology and interchangeable insert approach allowed us to test multiple designs and materials efficiently. Their precision manufacturing saved us months of development time."

Medical Tech Product Development Guide

Navigate the complex journey from concept to market with our comprehensive development framework for medical devices.

Design & Planning

-

Regulatory ResearchFDA, CE, ISO requirements analysis

-

Material SelectionBiocompatible material guidance

-

DFM AnalysisDesign for manufacturability review

Prototyping

-

Rapid PrototypingCNC machined functional prototypes

-

Testing SupportMechanical & biocompatibility testing

-

Iterative DesignMultiple revision cycles

Production

-

Scalable ManufacturingFrom pilot runs to mass production

-

Quality AssuranceComplete traceability & documentation

-

Regulatory SupportDocumentation for approvals

Critical Success Factors

Medical Part Gallery

Explore our portfolio of precision-manufactured medical components across various specialties and applications.

Resources for Medical Manufacturing

Comprehensive guides and insights for medical device manufacturing, covering precision requirements, regulatory compliance, and industry best practices.

Medical CNC Machining

Precision machining for medical implants, surgical instruments, and diagnostic equipment with biocompatible materials and FDA compliance.

Medical Injection Molding

High-precision molding for disposable medical devices, drug delivery systems, and laboratory equipment with medical-grade polymers.

Medical Stamping

Precision metal stamping for medical device components, surgical tools, and implant parts with stringent quality control standards.

Ready to Develop Your Medical Device?

From initial concept to FDA approval, our medical manufacturing experts guide you through every step of the development process.