Powering the

Clean Energy

Revolution

From solar panel components to EV charging infrastructure, Xu Feng delivers precision manufacturing for renewable energy applications with ISO-certified quality assurance.

Manufacturing for Sustainable Future

Precision components for solar, wind, EV charging, energy storage, and smart grid applications with QAS quality assurance.

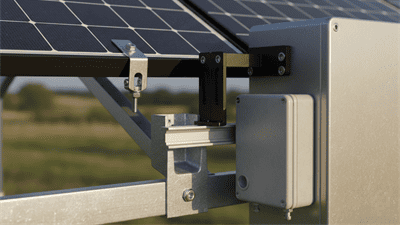

Solar Energy Systems

- Panel mounting systems

- Inverter enclosures

- Tracking mechanisms

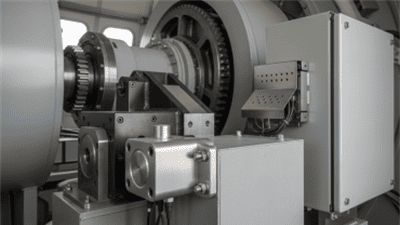

Wind Power Components

- Turbine components

- Control system parts

- Power transmission

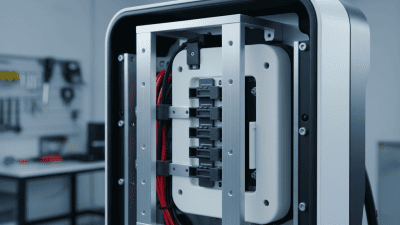

EV Charging Infrastructure

- Charging station enclosures

- Cable management

- Power electronics housing

Energy Storage Systems

- Battery pack housing

- Cooling system parts

- BMS components

Smart Grid Technology

- Smart meter components

- Grid automation parts

- Monitoring equipment

Hydrogen Energy Systems

- Fuel cell housings

- Storage tank components

- Electrolysis parts

Rigorous Quality Standards for Clean Energy Manufacturing

Our comprehensive Quality Assurance System ensures every component meets the stringent requirements of renewable energy applications, from material certification to final inspection.

ISO 9001:2015

Certified quality management system compliance

Material Traceability

Full material certification and batch tracking

CMM Inspection

Coordinate measuring machine verification

Detailed Reports

Comprehensive inspection documentation

QAS Process Flow for New Energy Components

Advanced Manufacturing Technologies

Three specialized factories equipped with cutting-edge technology to serve the demanding requirements of new energy applications.

Precision CNC Machining

CNC machining centers for complex geometries in aluminum, steel, and titanium with ±0.02mm tolerance capability.

- Heat sink manufacturing for power electronics

- Structural components for solar tracking systems

- Precision gears and transmission parts

Injection Molding

Advanced injection molding with engineering plastics, including glass-filled materials for high-strength applications.

- EV charging connector housings

- Solar panel junction boxes

- Battery management system enclosures

Approved Materials

Certifications & Standards

Resources for CleanTech Engineers

Expert insights, manufacturing guides, and industry trends to help you succeed in clean energy projects.

Precision Manufacturing for Solar Panel Components

Learn about critical tolerances, material selection, and quality control processes for solar mounting systems and junction boxes.

EV Charging Station Housing: Design & Manufacturing

Explore weatherproof enclosure requirements, thermal management solutions, and rapid prototyping for EV infrastructure.

Wind Turbine Component Manufacturing Challenges

Discover how advanced CNC machining and material expertise solve complex challenges in wind energy component production.

Turn Your CleanTech Ideas into

Manufacturing Reality

Whether you're developing solar components, EV charging infrastructure, or wind energy systems, Xu Feng's precision manufacturing expertise helps bring your sustainable technology to market faster.