Precision

3D Printing

for Plastic Parts

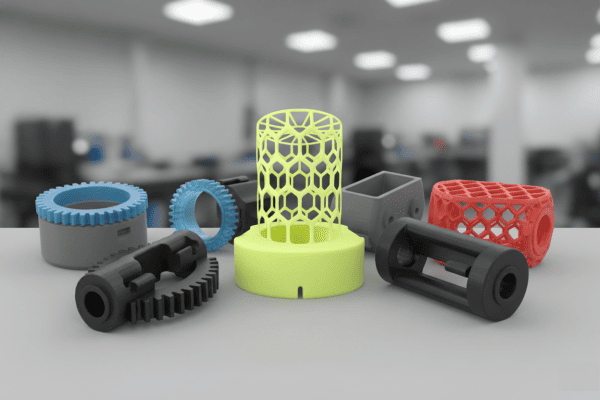

From rapid prototypes to functional parts, Xu Feng delivers high-quality 3D printed plastic components with advanced materials and precision finishing.

Advanced Printing Solutions

Multiple printing technologies and premium materials for every application, from prototyping to end-use parts.

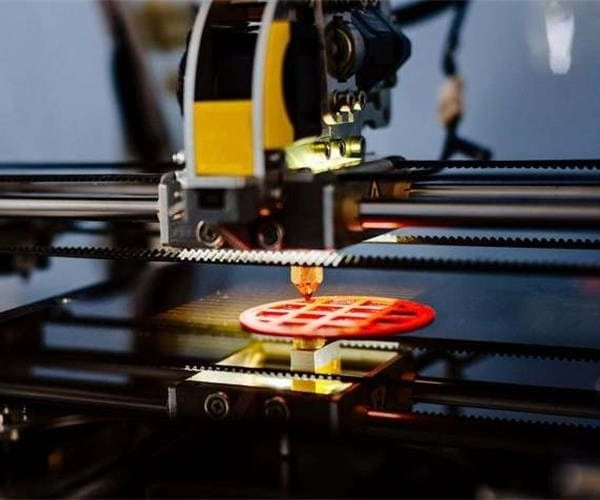

FDM Printing

Fused Deposition Modeling for durable functional parts with engineering-grade thermoplastics.

- PLA, ABS, PETG, Nylon

- Layer: 0.1-0.3mm

- Build: 300×300×400mm

SLA Printing

Stereolithography for ultra-smooth surface finish and fine details in photopolymer resins.

- Standard, Tough, Flexible Resin

- Layer: 0.05-0.1mm

- Build: 200×200×250mm

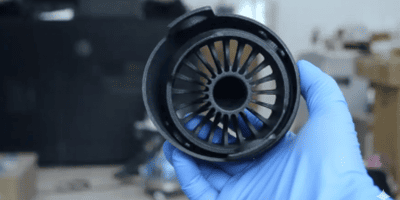

SLS Printing

Selective Laser Sintering for complex geometries without support structures in nylon powders.

- PA12, PA11, Glass-filled

- Layer: 0.1-0.15mm

- Build: 350×350×600mm

MJF Printing

Multi Jet Fusion for high-speed production with superior mechanical properties and fine detail.

- PA12, PA11, TPU

- Layer: 0.08-0.12mm

- Build: 380×284×380mm

Premium Plastic Materials

Engineering Plastics

High-performance thermoplastics

- • ABS, PC, Nylon

- • TPU, PP

- • Carbon Fiber filled

Photopolymers

UV-cured liquid resins

- • Standard Resin

- • Tough, Flexible

- • Castable, Dental

Biodegradable

Eco-friendly options

- • Silicone, PLA, PHA

- • Wood-filled

- • Recycled materials

Specialty

Application-specific

- • Transparent

- • Conductive

- • High-temp resistant

On-Demand Access to

3D Print

from Xu Feng

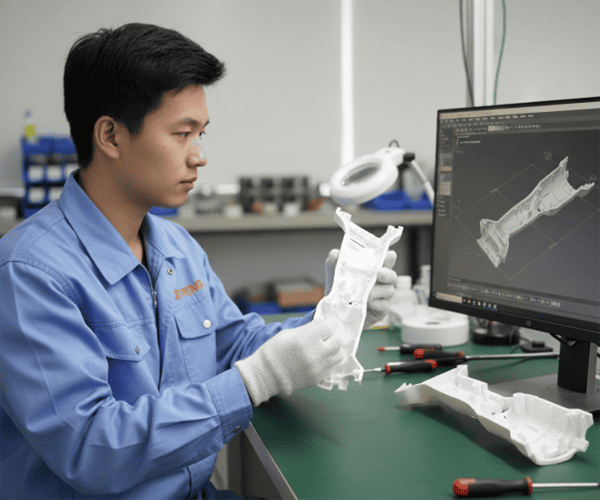

Transform your digital designs into physical reality with our advanced 3D printing capabilities. From rapid prototyping to small-batch production, we deliver precision parts with industry-leading materials and finishes.

From Prototyping to Production

Scale seamlessly from initial concept validation to full-scale manufacturing with our comprehensive production capabilities and engineering expertise.

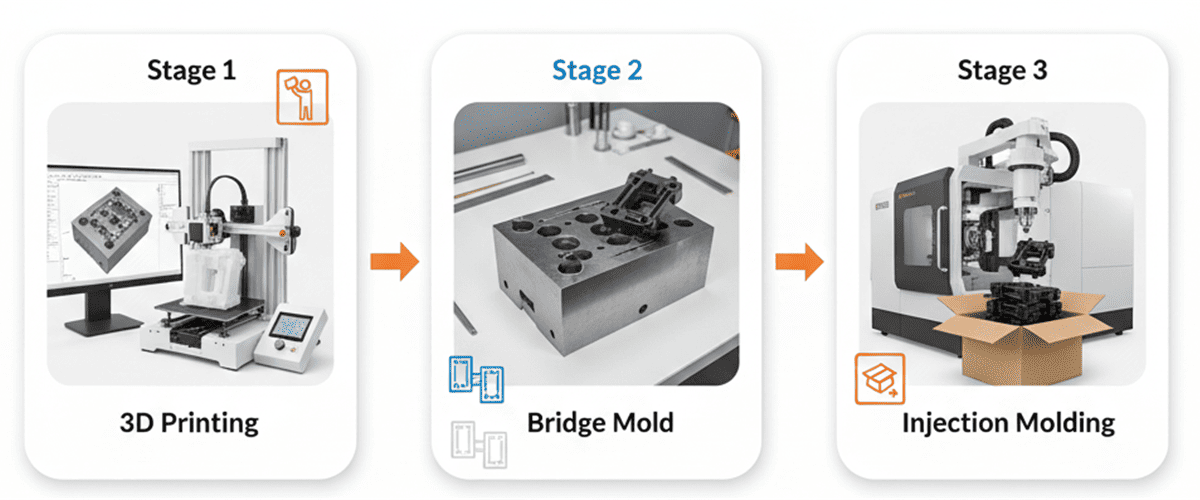

3D Printing

Quick parts to test fit, form, or function of designs at the early development stages.

Bridge Mold

More aesthetically and functionally representative models for middle development stages.

Injection Molding

100% production quality parts for testing, bridge production, and full production stages.

Seamless Scaling Across All Stages

Consistent Quality

Same precision standards from prototype to production with ±0.2mm tolerance control

Optimized Costs

Cost-effective solutions tailored to each production stage and volume requirement

Faster Time-to-Market

Accelerated development cycles with parallel engineering and manufacturing processes

Ready to start your manufacturing journey?