Low Volume

Aluminum

Extrusion

Specialized low volume aluminum extrusion services for prototypes, custom designs, and small batch production with rapid tooling and flexible manufacturing solutions.

What is Aluminum Extrusion?

Aluminum extrusion is a manufacturing process where aluminum alloy is heated and pushed through a shaped die to create complex cross-sectional profiles. This versatile process enables the production of lightweight, durable components for industries ranging from construction to aerospace.

Why Choose Aluminum Extrusion?

Complex Geometries

Create intricate cross-sections that would be impossible or costly with other manufacturing methods.

Material Efficiency

Minimal waste production and excellent strength-to-weight ratio for optimal performance.

Cost-Effective Production

Lower tooling costs compared to other forming processes, especially for medium to high volumes.

Our Aluminum Extrusion Capabilities

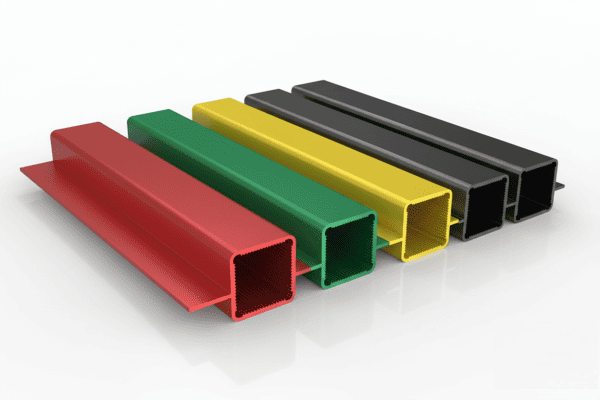

Profile Types

- Solid profiles (rods, bars, angles)

- Hollow profiles (tubes, channels)

- Semi-hollow complex shapes

- Custom designed profiles

Aluminum Alloys

- 6061-T6 (structural applications)

- 6063-T5 (architectural profiles)

- 6082-T6 (high strength)

- 7075-T6 (aerospace grade)

Size Capabilities

- Circle: Ø6mm - Ø250mm

- Rectangle: 300mm × 150mm max

- Length: Up to 1 meters

- Wall thickness: 1mm - 25mm

Industry Applications

Our aluminum extrusion combine CNC machining services support diverse industries with custom profiles engineered for specific performance requirements.

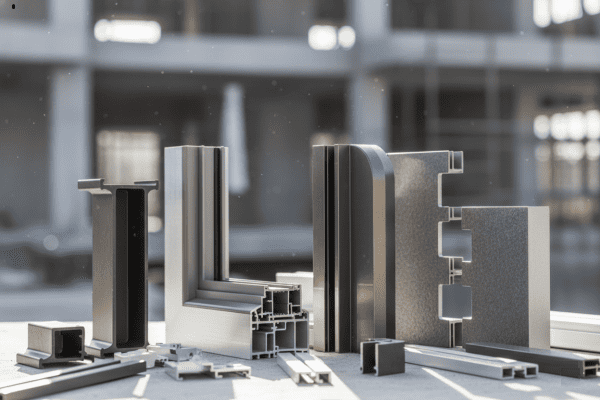

Construction Industry

Our precision aluminum extrusions provide the structural integrity and aesthetic appeal required for modern construction projects. From residential to commercial applications, we deliver custom profiles that meet strict building codes and performance standards.

Automotive Industry

Lightweight yet durable aluminum components for next-generation vehicles. Our automotive-grade extrusions meet stringent safety and performance requirements while contributing to fuel efficiency and emission reduction goals.

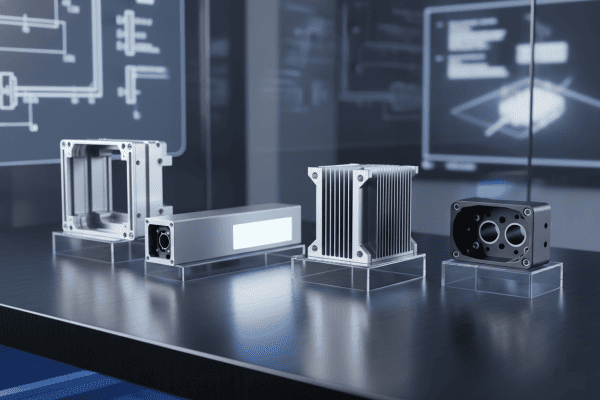

Electronics Industry

Precision thermal management and protective enclosures for sensitive electronic equipment. Our aluminum profiles provide excellent heat dissipation while maintaining electromagnetic compatibility and aesthetic appeal.

Industrial Equipment

Robust structural solutions for industrial automation and manufacturing equipment. Our heavy-duty aluminum profiles provide the strength and modularity needed for demanding production environments.

Our Aluminum Extrusion Process

From design optimization to final delivery, we ensure precision and quality at every step of the extrusion process.

Design & Engineering

Profile design optimization, die engineering, and DFM analysis for optimal manufacturability.

Die Manufacturing

Precision die machining and heat treatment for consistent profile quality and dimensional accuracy.

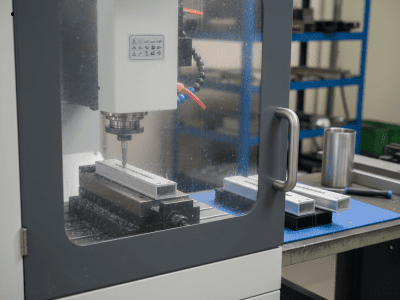

Extrusion Process

High-pressure aluminum extrusion with real-time monitoring for consistent quality control.

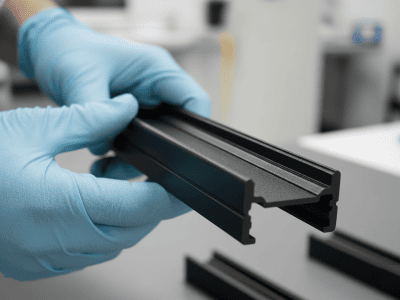

Finishing & QC

Cutting, machining, surface treatment, and comprehensive quality inspection before delivery.

Surface Treatments

Enhance your aluminum extrusions with professional surface treatments for improved durability, corrosion resistance, and aesthetic appeal.

Anodizing

- • Clear, black, or colored finishes

- • Type II (decorative) & Type III (hard coat)

- • Excellent wear resistance

Powder Coating

- • Wide range of colors and textures

- • Excellent UV and weather resistance

- • Environmentally friendly process

Secondary Machining

- • Drilling, tapping, milling operations

- • Precision cutting and notching

- • Assembly hole patterns

Ready for Your

Custom Aluminum Extrusion Project?

Upload your profile drawings and specifications to receive a detailed quote with die cost analysis and production timeline within 24 hours.