Quality Assurance

at Every Step

From incoming materials to final inspection, our rigorous quality control processes ensure every part meets your exact specification.

Quality Policy:

-

Understanding customer detailed quality requirements

-

Meeting the requirements through continual QMS improvement

-

Providing parts meet the quality requirement with competitive cost

Rigorous Quality Standards

Our comprehensive quality assurance system ensures consistent precision across all manufacturing processes, from material verification to final inspection.

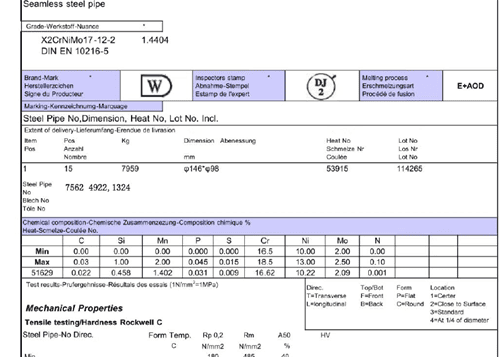

Incoming Material Inspection

Every raw material batch undergoes chemical composition analysis, dimensional verification, and material certification review before production.

-

Chemical Composition VerificationSpectroscopic analysis ensures material grade compliance

-

Material Hardness TestingRockwell and Brinell hardness validation

-

Dimensional Pre-verificationStock material dimensional accuracy check

-

Mill Test Certificate ReviewSupplier certification and traceability verification

Quality Inspection Capabilities

Xu Feng offers a wide range of quality inspection services with state-of-the-art equipment.

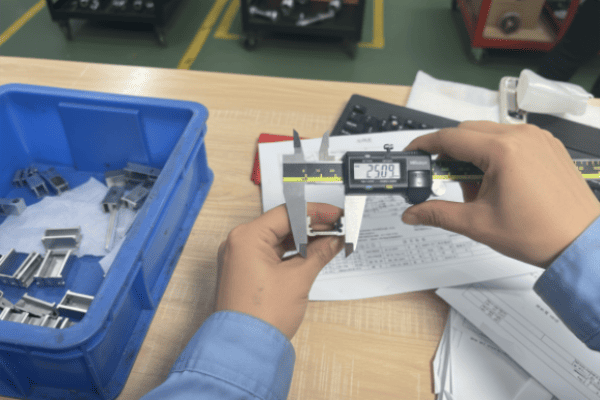

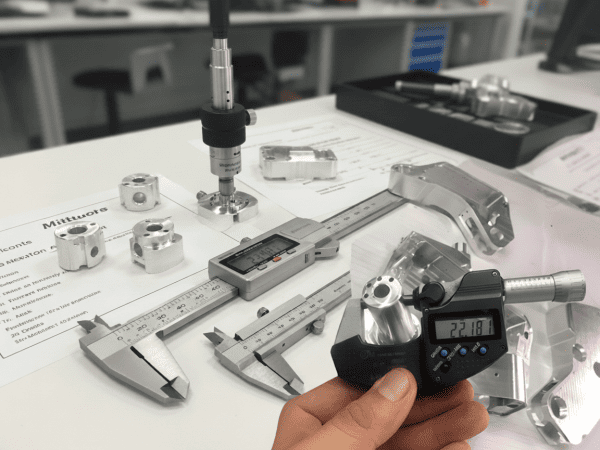

Array of Micrometers and Calipers

Precision dimensional measurement tools for accurate part verification

A Wide Range of Gauges

Specialized gauging systems for consistent quality control

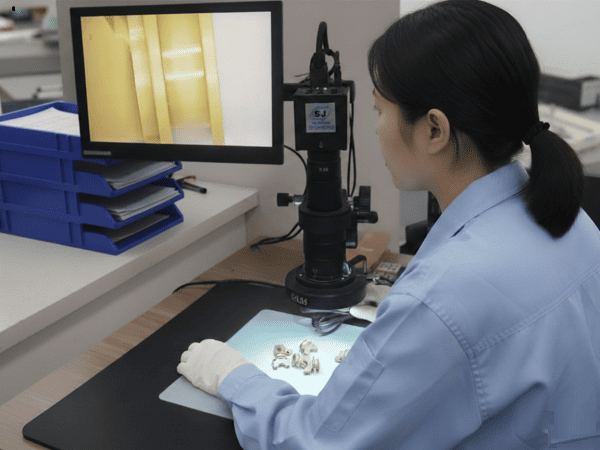

Surface Testing

Surface roughness and finish quality verification

Precision Complex Measurements

Advanced metrology for complex geometries and tight tolerances

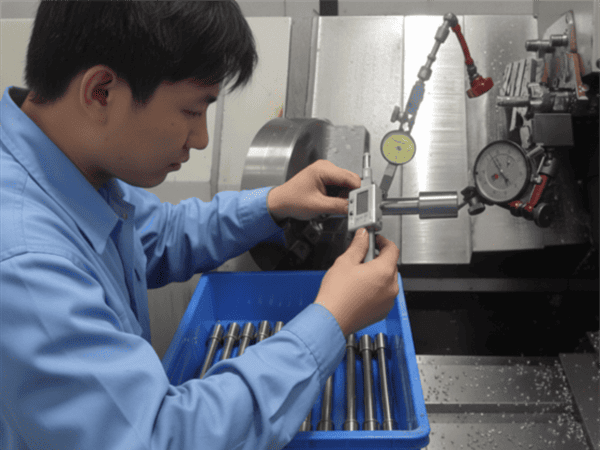

CNC Online Measurements

Real-time in-process measurement and quality monitoring

Certified Excellence

Our comprehensive quality management systems ensure consistent processes, continuous improvement, and exceptional customer satisfaction across all manufacturing operations.

-

ISO 9001:2015 Quality Management

-

Statistical Process Control (SPC)

-

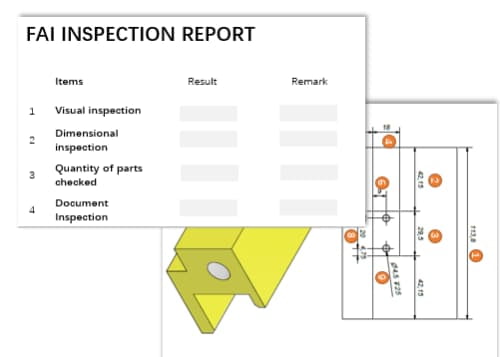

First Article Inspection (FAI)

-

Traceability & Documentation

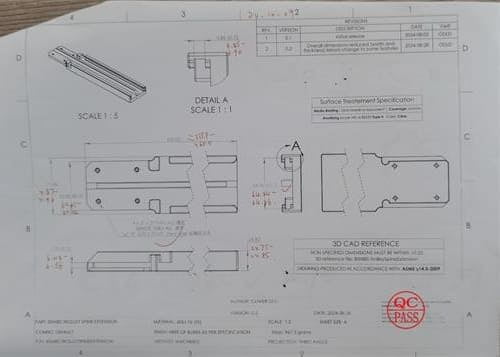

Precision Documentation Compliance

Complete certification package ensuring regulatory compliance and quality standards for every manufactured component.

-

Material Certificates

-

REACH and RoHS

-

Certificates of Analysis

-

GD&T per ISO 2768 (unless 2D drawing provided)

-

Finishing, testing, inspection, and compliance industry standards met

Quality Standards We Meet

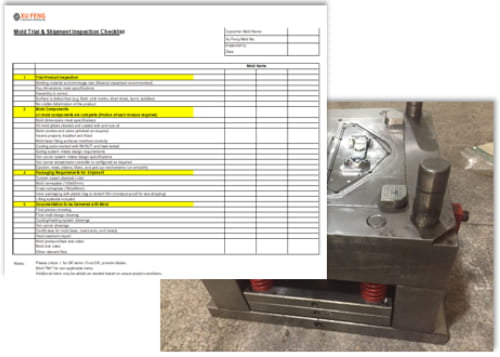

Complete Documentation

Comprehensive quality documentation with full traceability and specification compliance verification.

First Article Inspections

Material Certificate

Dimensional Inspection

Advanced Inspection

Mold Inspection

Other Special Report

Shipment Work

We don't just check quality before shipment -- we take full responsibility for getting your parts to you safely and on time.

Tracking Orders After Shipment

Small orders are shipped via trusted express couriers such as DHL, FedEx, and UPS, securely packed in durable carton boxes

Bulk orders are shipped by sea, using pallets or wooden crates to ensure your parts arrive in perfect condition

You will receive a Tracking Number and Estimated Time of Arrival (ETA) immediately after the goods are picked up

Stay informed at every step -- we provide regular tracking updates until your shipment reaches your facility

Customs Clearance

Package via express couriers, we won't be able to handle customs directly. But we can assist you with documentation and other types of support if need be

We can handle customs for orders to the UK, US, and countries within the EU with the help of freight forwarder. We ship Delivered Duty Paid (DDP)

We can't handle customs for orders to other countries. But we can assist you with documentation and other types of support if you need

What People Say About Us

Don't just take our word for it -- hear what our clients have to say about working with us.

Let's Bring Your Design

to Manufacturing Reality

Upload your CAD files today and receive a detailed quote with DFM analysis within 24 hours. From Australia to Europe, we're your trusted manufacturing partner.