Precision

CNC Machining

Manufacturing

High-quality custom CNC machining services for prototypes and production parts. From simple components to complex geometries, we deliver precision parts with fast turnaround times.

Your Trusted Manufacturing Partner

From prototype to production, we deliver precision manufacturing with engineering excellence, quality assurance, and global reach across 25+ countries.

Lightning-Fast Turnaround

24-hour quote response with detailed DFM analysis

Engineering Excellence

±0.005mm precision tolerance with first article inspection

Worldwide Shipping

Reliable delivery to 25+ countries with full tracking

ISO-Certified Quality

ISO 9001:2015 certified with comprehensive quality control

Scalable Production

From prototype to mass production: 1 to 1M+ parts capacity

Advanced Equipment

State-of-the-art 5-axis CNC machining capability

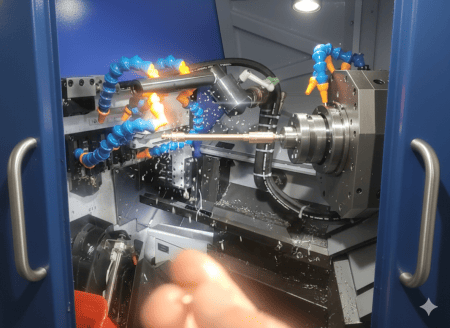

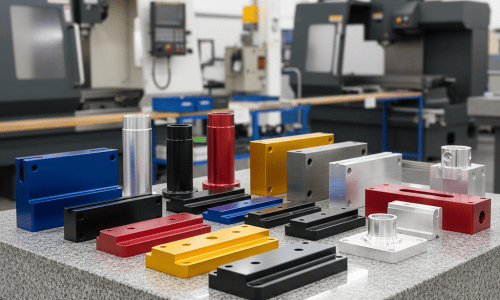

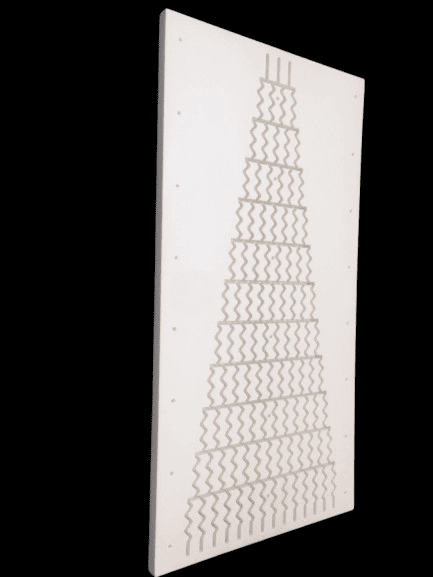

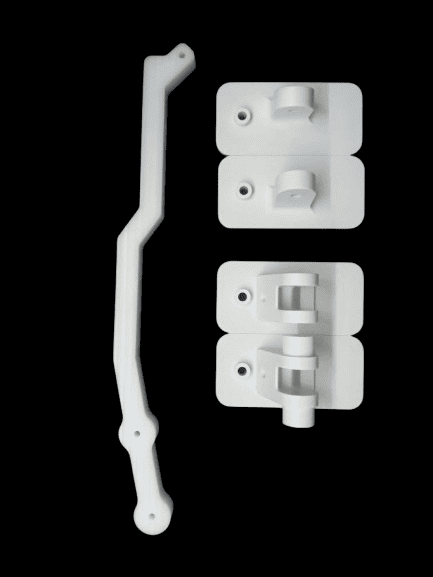

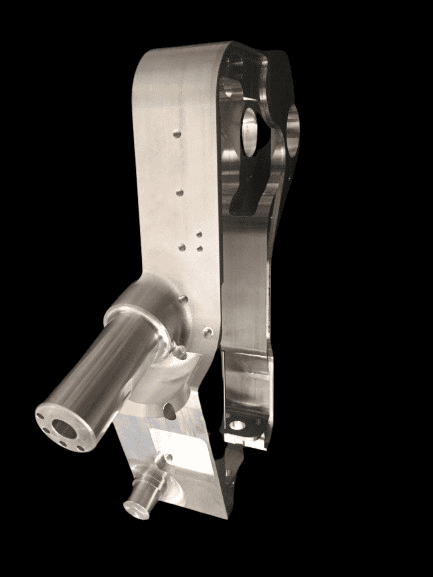

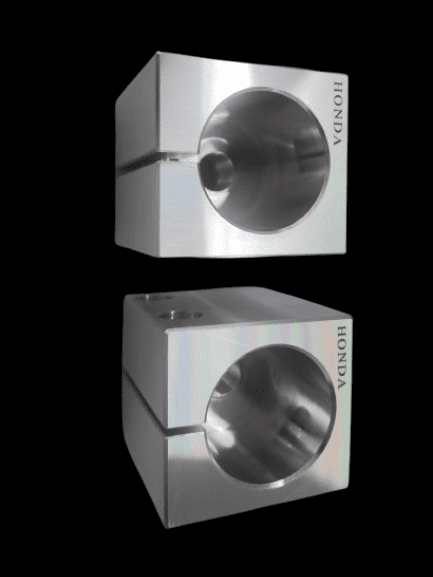

Manufacturing Excellence

See our precision manufacturing process in action

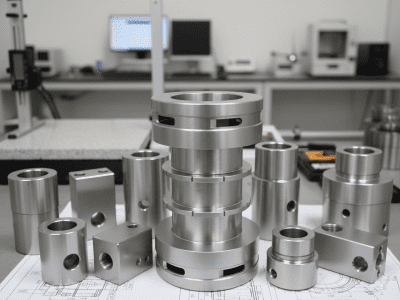

Trusted by Industry Leaders

From medical devices to aerospace components, our precision manufacturing supports critical applications across diverse industries worldwide.

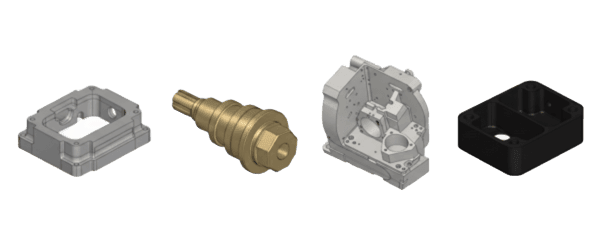

Complete Machining Solutions

Our state-of-the-art CNC machining center features advanced equipment capable of producing complex geometries with exceptional precision and surface finish quality.

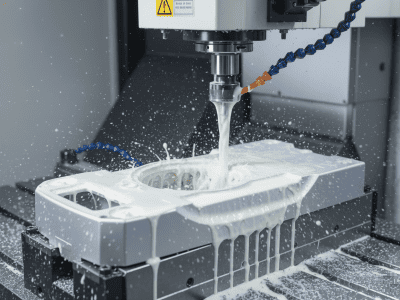

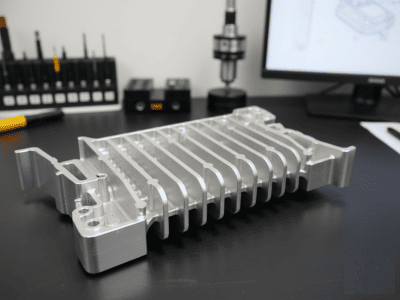

CNC Milling

High-precision 3-5 axis milling for complex surfaces, slots, holes, and contours with excellent surface finish quality.

- • Work envelope: 1200×800mm

- • Spindle speed: 24,000 RPM

- • Tolerance: ±0.01mm

- • Surface finish: Ra 0.8μm

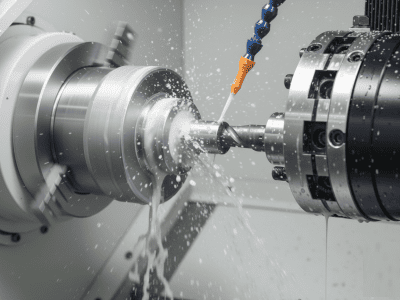

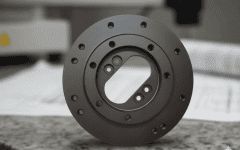

CNC Turning

Precision turning operations for cylindrical parts, shafts, bushings, and rotational components with live tooling.

- • Max diameter: 500mm

- • Max length: 1000mm

- • Live tooling capability

- • Sub-spindle for complex parts

EDM & Wire-Cut

Electrical discharge machining for intricate profiles, tight tolerances, and hardened materials up to 65 HRC.

- • Thickness up to 100mm

- • Tolerance: ±0.005mm

- • Surface finish: Ra 0.8μm

- • Hardened material capability

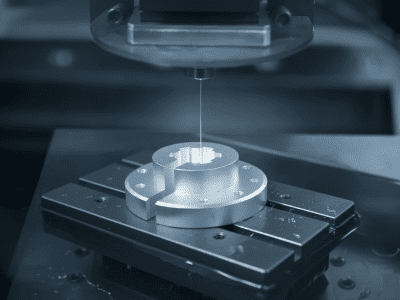

CNC Grinding

Ultra-precision surface and cylindrical grinding for superior surface finish and dimensional accuracy.

- • Surface finish: Ra 0.4μm

- • Tolerance: ±0.005mm

- • Hardness up to 65 HRC

- • Mirror finish capability

Gear Hobbing

Precision gear cutting and hobbing for spur, helical, and worm gears with various modules and pitch diameters.

- • Module range: 0.5-10mm

- • Max diameter: 800mm

- • Precision grade: DIN 5-8

- • Helical angle: ±45°

Swiss Machining

High-precision, high-volume production of small diameter parts with exceptional accuracy and surface finish.

- • Diameter range: 0.5-32mm

- • Length up to 100mm

- • Tolerance: ±0.01mm

- • High-volume production

Comprehensive Material Library

We machine a wide range of materials to meet diverse industry requirements, from standard alloys to exotic aerospace materials with certified quality standards.

Aluminum Alloys

- 6061-T6, 6063-T5

- 7075-T6 (Aerospace)

- 2024-T4 (Aircraft)

- 5083 (Marine Grade)

Steel & Alloys

- Carbon steel 1018, 1045

- Stainless 304, 316, 17-4PH

- Tool steel H13, D2, A2

- Alloy steel 4140, 4340

Titanium Alloys

- Ti-6Al-4V (Grade 5)

- CP Titanium Grade 2

- Ti-6Al-2Sn-4Zr-2Mo

- Medical grade Ti

Specialty Materials

- Inconel 625, 718

- Hastelloy C-276

- Copper alloys

- Engineering plastics

Your Material Selection

Assistant

Not sure which material is right for your application? Our comprehensive material guide helps you choose the optimal material based on your specific requirements including strength, corrosion resistance, temperature, and cost considerations.

CNC Machining Finishes

Professional surface treatments and finishes to enhance appearance, durability, and performance of your CNC machined parts.

Anodizing

Electrochemical process creating a durable, corrosion-resistant oxide layer on aluminum parts with excellent wear resistance and multiple color options.

- Type II & Type III anodizing available

- Multiple colors: Clear, Black, Blue, Red, Gold

- Thickness: Type II 5-12μm standard, >20μm hard coat

- Applications: Aerospace, Electronics, Consumer goods

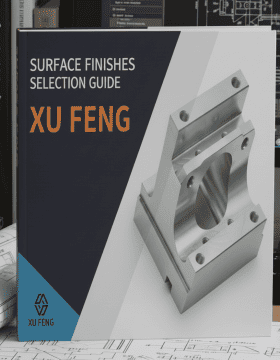

Surface Finish Selection Guide

Master surface finishing with our comprehensive guide. Learn to select the perfect finish for your manufacturing project.

- Complete finish comparison charts

- Cost and lead time considerations

- Application-specific recommendations

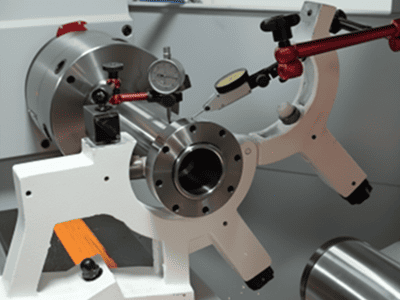

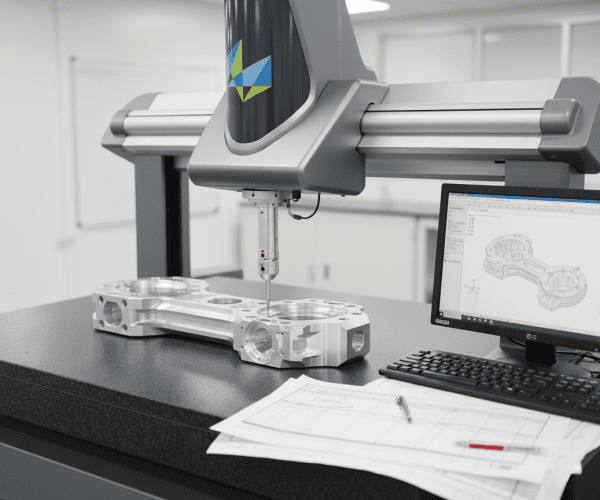

ISO-Certified Quality Control

Our comprehensive quality management system ensures every CNC machined part meets the highest standards through rigorous inspection protocols and advanced measurement equipment.

First Article Inspection (FAI)

Complete dimensional verification of initial production parts with detailed inspection reports and CMM measurements.

In-Process Monitoring

Real-time quality control during machining operations with automated measurement and feedback systems.

Statistical Process Control

Data-driven quality management with SPC charts, capability studies, and continuous improvement protocols.

CMM Inspection

3D coordinate measuring machines for precise dimensional verification

Optical Measurement

High-resolution optical comparators and vision systems

Surface Analysis

Profilometers for surface roughness and texture verification

Material Testing

Hardness testing, material composition verification

CNC Machining Tolerances and Standards

Our advanced CNC machining centers deliver exceptional precision across various tolerance ranges to meet your exact specifications.

View Complete Tolerance GuideTolerance Capabilities Overview

Comprehensive precision specifications for different application requirements

| Tolerance Level | Metric (mm) | Imperial (in) | Applications | Industries |

|---|---|---|---|---|

|

Ultra-High Precision

Maximum accuracy

|

±0.005 | ±0.0002" |

• Medical implants

• Optical components

• Gauge blocks

|

Medical

Aerospace

Semiconductor

|

|

High Precision

Strict requirements

|

±0.01 | ±0.0004" |

• Engine components

• Connector housings

• Precision fixtures

|

Automotive

Electronics

Machinery

|

|

Standard Precision

Reliable accuracy

|

ISO2768-mK | ISO2768-mK |

• Industrial brackets

• Prototype parts

• Mounting hardware

|

Industrial

Prototyping

General

|

|

Commercial Grade

Cost-effective

|

±0.1 | ±0.004" |

• Enclosures

• Basic fixtures

• Non-critical parts

|

Consumer

Commercial

Basic

|

Surface Finish Standards

| Finish Grade | Ra Value | Application |

|---|---|---|

| Mirror | Ra 0.4μm | Optical, Medical |

| Fine | Ra 0.8μm | Precision Parts |

| Standard | Ra 1.6μm | General Purpose |

| Rough | Ra 3.2μm | Non-critical |

Geometric Tolerances (GD&T)

| Control | Tolerance | Verification |

|---|---|---|

| Flatness | ±0.01mm | CMM |

| Position | ±0.02mm | CMM |

| Parallelism | ±0.01mm | CMM |

| Perpendicularity | ±0.01mm | CMM |

Precision CNC Parts Made by Xu Feng

From aerospace components to medical devices, our CNC machining capabilities deliver exceptional precision and quality across diverse industries.

Frequently Asked Questions

Get answers to common questions about our CNC machining services, pricing, and lead times. Our engineering team is here to help with your specific requirements.

Still have questions?

Our engineering team is ready to help you with your specific CNC machining needs.

Contact Us