Professional

CNC Milling

Services

From prototypes to mass production, Xu Feng delivers precision CNC milling services with tolerances as tight as ±0.01mm for complex metal components.

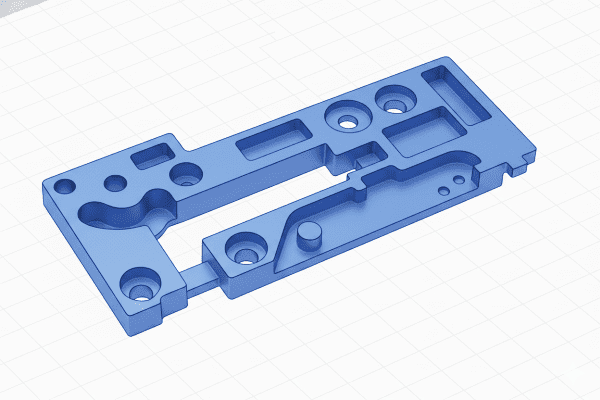

What is CNC Milling?

CNC milling is a precision machining process that uses computer-controlled rotating cutting tools to remove material from a workpiece, creating complex geometries with exceptional accuracy and surface finish quality.

High Precision

Achieve tolerances as tight as ±0.01mm with our advanced 3-5 axis CNC milling centers.

Complex Geometries

Machine intricate features, undercuts, and complex 3D surfaces with multi-axis capabilities.

Cost Effective

Scalable from prototypes to medium-volume production with excellent material utilization.

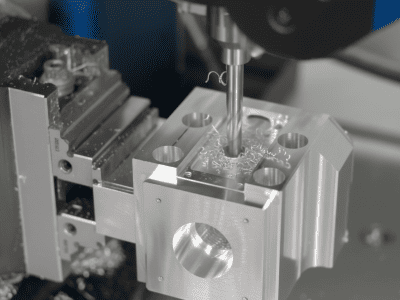

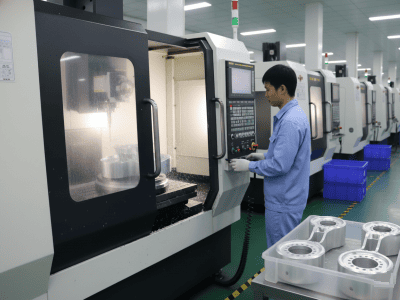

Our CNC Milling Capabilities

State-of-the-art equipment and experienced machinists deliver precision parts across a wide range of materials and specifications.

3-Axis Milling

Versatile machining for flat surfaces, slots, holes, and basic contours with excellent surface finish.

- Work envelope: 1000×600×500mm

- Spindle speed: 8,000 RPM

- Tool capacity: 20 positions

4-Axis Milling

Rotary axis capability for cylindrical features and complex angular surfaces with continuous machining.

- Rotary table: 360° continuous

- Simultaneous 4-axis interpolation

- Reduced setup time

5-Axis Milling

Complete part machining in single setup with complex undercuts and compound angles.

- Full 5-axis simultaneous

- Complex aerospace parts

- Superior surface finish

Materials We Machine

From aerospace-grade titanium to high-performance plastics, we machine the toughest materials with precision and expertise.

Aluminum Alloys

6061, 7075, 2024

Excellent machinability

Steel Alloys

Carbon, Stainless

Tool steels, Hardened

Titanium

Ti-6Al-4V, CP Grade

Aerospace applications

Specialty Alloys

Inconel, Hastelloy

Copper, Brass

Engineering Plastics

PEEK, POM, Nylon

PC, ABS, PP

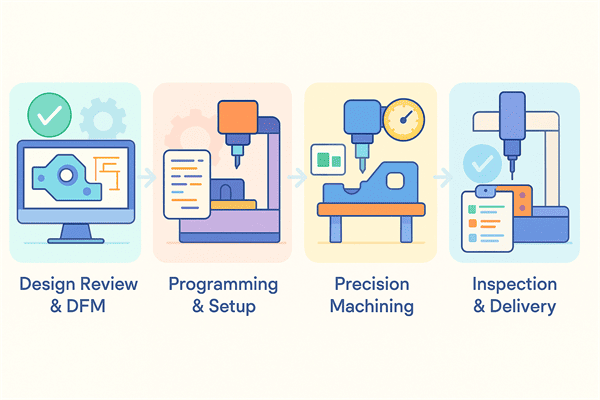

Our CNC Milling Process

From design review to final inspection, our systematic approach ensures consistent quality and on-time delivery.

Design Review & DFM

CAD analysis, manufacturability assessment, and optimization recommendations within 24 hours.

Programming & Setup

CAM programming, toolpath optimization, and fixture design for efficient machining.

Precision Machining

Multi-axis CNC milling with real-time monitoring and quality control checkpoints.

Inspection & Delivery

CMM measurement, surface finish verification, and comprehensive inspection reports.

Quality Assurance Standards

ISO-certified processes ensure consistent quality and traceability

ISO 9001:2015

Quality management system certification

First Article

100% dimensional inspection before production

Statistical Process

SPC monitoring and control charts

Material Certs

Full material traceability and certificates

Proven Manufacturing Excellence

Real projects, real results. Discover how we've helped companies across industries achieve their manufacturing goals with precision and reliability.

Precision Surgical Instruments

Delivered 50,00+ biocompatible titanium surgical components with ±0.008mm tolerance for a leading medical device manufacturer in the USA.

Industrial Robot Frames

Custom aluminum robot chassis and joint components for a Canadian automation company, reducing assembly time by 40% through optimized design.

Electronics Housings

Mass production of 50K+ precision aluminum housings for a European electronic sensor brand, achieving 98.5% quality pass rate.

Comprehensive Resources for CNC Milling

Everything you need to optimize your CNC milling projects - from design guidelines to finishing options and precision tolerances.

Design Tips

Finishing Options

Tolerance Chart

Need Custom Engineering Support?

Our engineers provide complimentary DFM analysis and design optimization recommendations with every quote.