Professional

CNC Turning

Services

High-precision CNC turning for complex cylindrical parts with ±0.005mm tolerance. From prototypes to mass production, we deliver quality turned components for critical applications.

What is CNC Turning?

CNC turning creates precise cylindrical parts by rotating the workpiece while cutting tools shape the material with exceptional accuracy and superior surface finishes.

Our advanced multi-axis lathes with live tooling perform drilling, milling, and threading in single setups for maximum precision and efficiency.

CNC Turning Capabilities

Advanced CNC turning capabilities for precision cylindrical components across various industries and applications.

Machine Specifications

- Max diameter: Ø500mm

- Max length: 1000mm

- Spindle speed: up to 4000 RPM

- Multi-axis capability (up to 5-axis)

Precision & Tolerance

- Tolerance: ±0.005mm

- Surface finish: Ra 0.8μm

- Roundness: 0.01mm

- Concentricity: 0.01mm

Materials

- Aluminum alloys (6061, 7075)

- Stainless steel (304, 316, 420)

- Carbon steel, Titanium

- Brass, Copper, Plastics

CNC Turning Design Tips

Optimize your turning parts for better manufacturability, cost efficiency, and quality outcomes

Wall Thickness

Maintain minimum 0.5mm wall thickness to prevent deflection and ensure dimensional accuracy

Corner Radii

Use R0.2-0.5mm corner radii to reduce stress concentration and improve tool life

Groove Design

Keep groove width ≥3× depth and avoid sharp internal corners for better chip evacuation

Surface Finish

Specify realistic surface finish requirements - Ra 1.6μm is standard, Ra 0.8μm for precision

Tolerance Zones

Apply tight tolerances only where needed - standard ±0.1mm, precision ±0.02mm for critical dimensions

Access our comprehensive DFM guidelines and manufacturing best practices

CNC Turning Applications

Our CNC turning services serve diverse industries with precision cylindrical components for critical applications.

Common Turned Parts

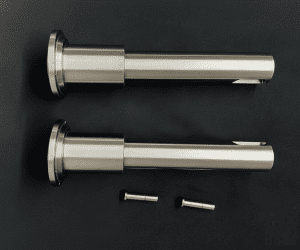

- Shafts and spindles

- Bushings and sleeves

- Pins and dowels

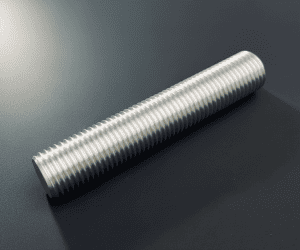

- Threaded rods

- Flanges and couplings

Target Industries

- Automotive components

- Aerospace parts

- Medical devices

- Industrial equipment

- Electronics & robotics

Key Advantages

- High production efficiency

- Excellent surface finish

- Tight dimensional control

- Complex geometry capability

- Cost-effective for volume

Sample CNC Turned Parts

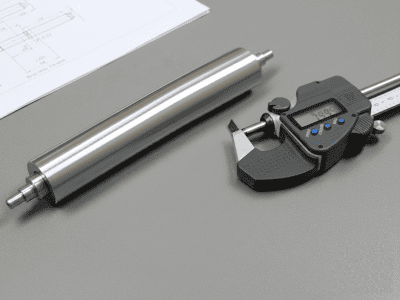

Precision Shaft

Stainless steel, ±0.005mm tolerance

Threaded Rod

Aluminum 6061, custom threading

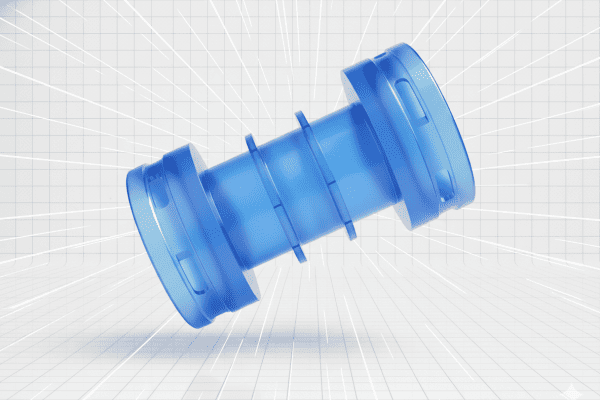

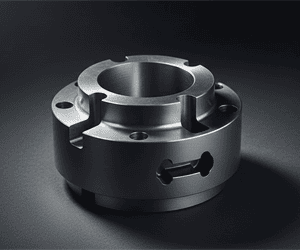

Bushing Assembly

Brass, high-precision bore

Custom Coupling

Steel, complex geometry

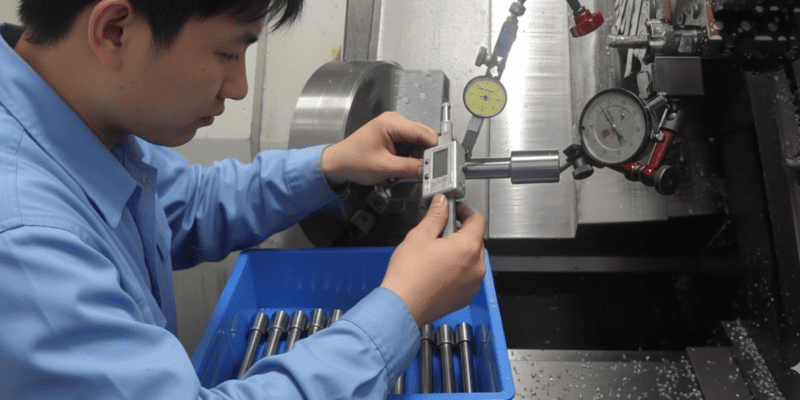

Precision You Can Trust

ISO-certified quality control ensures every part meets your exact specifications with advanced inspection and full documentation.

Advanced Inspection

Online inspection and dimensional analysis for critical tolerances.

Surface Quality

Precision surface finish measurement and verification.

Full Documentation

Complete inspection reports and material certificates.

Comprehensive Resources for CNC Turning

Everything you need to make informed decisions about materials, finishes, and tolerances for your precision turning projects.

Material Choice

Surface Finish

Tolerance Chart

Need Custom Specifications?

Our engineering team can help you select the optimal material, finish, and tolerances for your specific application requirements.