Precision

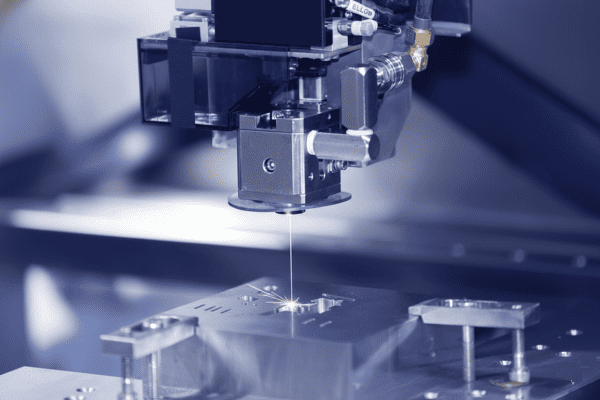

EDM & Wire-Cut

Manufacturing

Achieve unmatched precision with our advanced Electrical Discharge Machining and Wire-Cut EDM capabilities. From complex geometries to ultra-tight tolerances, we deliver excellence in every spark.

EDM & Wire-Cut Expertise

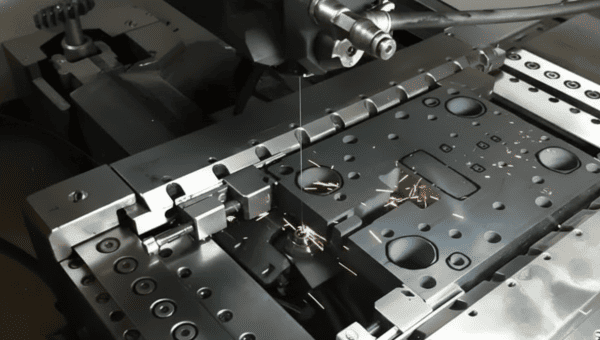

Our state-of-the-art EDM facilities combine precision engineering with advanced automation to deliver complex parts that conventional machining cannot achieve.

Conventional EDM (Ram EDM)

Perfect for creating complex internal cavities, blind holes, and intricate shapes in hardened materials. Our conventional EDM machines deliver exceptional surface finishes and dimensional accuracy.

- Complex internal geometries

- Hardened steel up to 62 HRC

- Surface finish Ra 0.4-0.8μm

- Electrode design & manufacturing

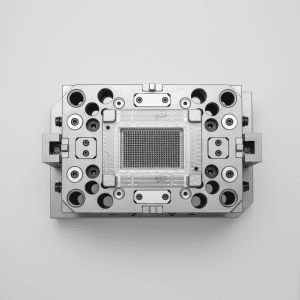

Wire-Cut EDM (WEDM)

Ultra-precise cutting for complex 2D and 3D profiles with exceptional accuracy. Ideal for punching dies, cutting tools, and precision components requiring tight tolerances.

- Tolerance ±0.002mm

- 4-axis simultaneous cutting

- Taper cutting up to ±30°

- Maximum thickness 300mm

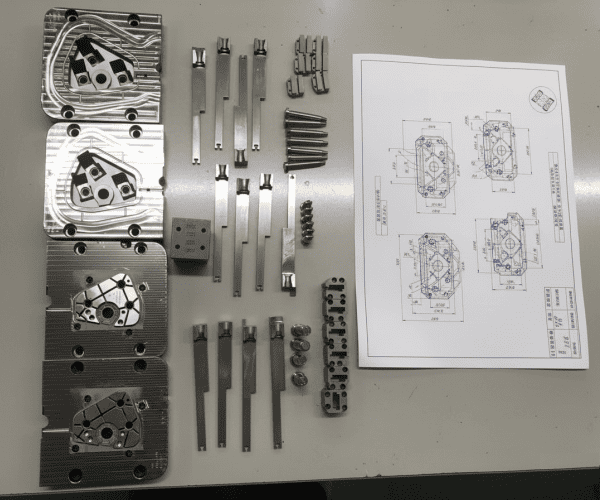

Injection Mold Inserts

Complex cooling channels and intricate cavity details

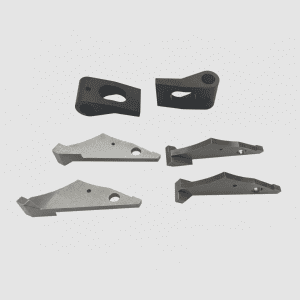

Stamping Dies

Progressive and transfer die components

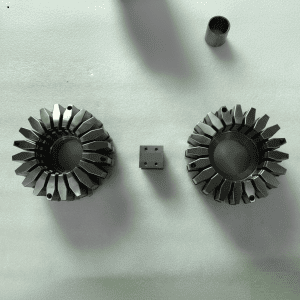

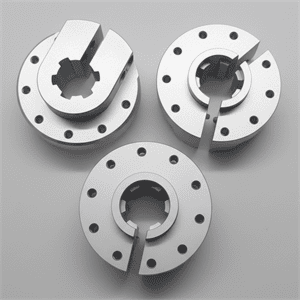

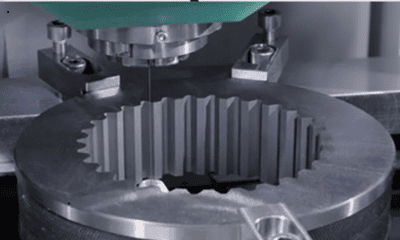

Precision Gears

Complex gear profiles and splines

Electronic Components

Semiconductor and connector parts

Technical Specifications

State-of-the-art equipment delivering precision results for the most demanding applications.

Conventional EDM

Ram EDM Specifications

Performance Specifications

Wire-Cut EDM

WEDM Specifications

Performance Specifications

Gear Hobbing

Precision Gear Manufacturing

Performance Specifications

Materials & Industries

Our EDM capabilities handle the toughest materials across diverse industries, from aerospace-grade alloys to hardened tool steels.

Compatible Materials

Target Industries

Process Excellence & Quality Control

Our EDM process combines advanced technology with rigorous quality control to ensure every part meets your exact specifications.

Quality Assurance

- • CMM dimensional inspection

- • Surface roughness testing

- • First article inspection

- • ISO 9001:2015 certified

Advanced Technology

- • Adaptive control systems

- • Automatic wire threading

- • Multi-axis simultaneous cutting

- • Real-time process monitoring

Fast Turnaround

- • 24-hour quote response

- • 5-7 days typical lead time

- • Rush orders available

- • Prototype to production

Resources for EDM & Wire-Cut

Comprehensive guides and insights to help you understand EDM machining capabilities and optimize your manufacturing projects.

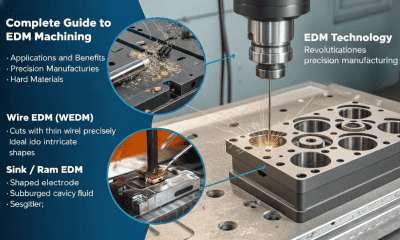

Complete Guide to EDM Machining: Applications and Benefits

Discover how Electrical Discharge Machining revolutionizes precision manufacturing for complex geometries and hard materials.

Wire-Cut EDM: Achieving ±0.002mm Precision in Complex Parts

Learn how wire-cut EDM technology enables ultra-precise manufacturing for intricate mold components and dies.

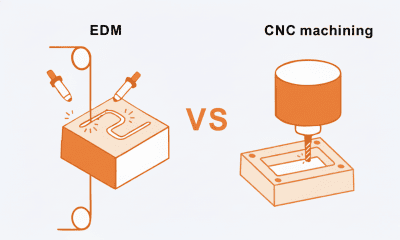

EDM vs CNC Machining: Choosing the Right Process for Your Project

Compare EDM and CNC machining capabilities to make informed decisions for your manufacturing requirements.

Quality Parts We Manufacture

Let's Bring Your Design

to Manufacturing Reality

Upload your CAD files today and receive a detailed quote with DFM analysis within 24 hours. From Australia to Europe, we're your trusted manufacturing partner.