Professional

Gear Hobbing

Services

Specialized metal and plastic gear manufacturing with advanced hobbing technology. From prototype gears to high-volume production with precision tolerances.

Complete Gear Hobbing Solutions

Advanced hobbing technology for metal and plastic gears with precision engineering and quality assurance.

Metal Gears

Precision hobbed steel, aluminum, brass, and stainless steel gears for industrial applications.

- Steel (1045, 4140, 8620H)

- Aluminum 6061, 7075

- Stainless Steel 316, 304

- Heat treatment available

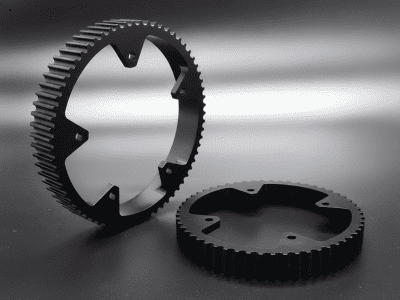

Plastic Gears

Lightweight, corrosion-resistant plastic gears for consumer products and light-duty applications.

- Nylon (PA6, PA66)

- POM (Delrin)

- PEEK for high-temp

- Glass-filled variants

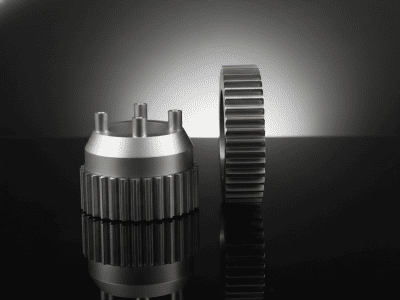

Custom Solutions

Specialized gear designs with custom tooth profiles, helical gears, and complex gear assemblies.

- Helical & bevel gears

- Worm gears

- Planetary gear sets

- DFM consultation

Technical Specifications

Gear Manufacturing Process

From design analysis to final inspection, our systematic approach ensures every gear meets your exact specifications.

Design Review & DFM

Technical analysis of gear specifications, material selection, and manufacturability assessment with optimization recommendations.

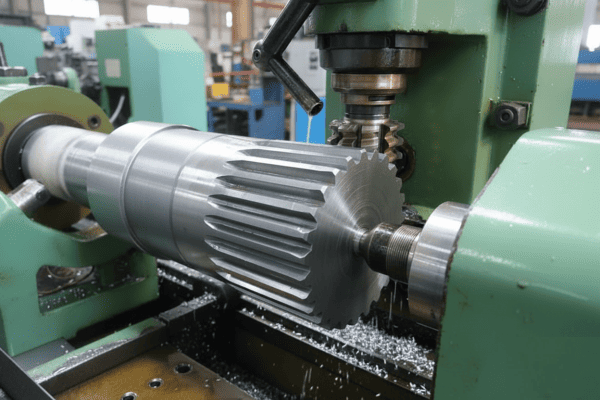

Hob Selection & Setup

Precision hob cutter selection based on module, pressure angle, and material. CNC hobbing machine setup and calibration.

Precision Hobbing

CNC-controlled hobbing process with real-time monitoring. Optimized cutting parameters for surface finish and dimensional accuracy.

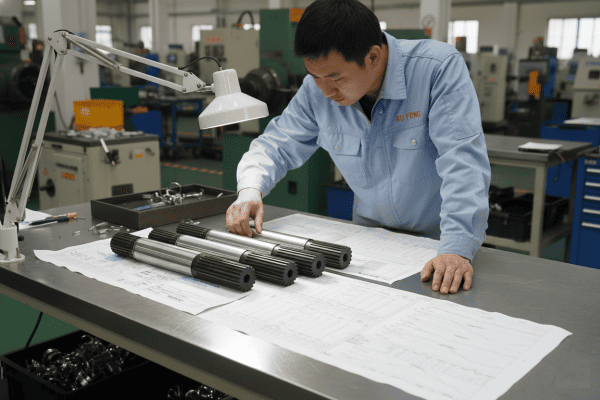

Quality Inspection

CMM measurement of tooth profile, pitch accuracy, and runout. Complete dimensional report with gear quality certification.

Precision Transmission

Spline Production

Challenge

Complex 24-tooth spline geometry in hardened steel (HRC 35-42) with strict tolerance requirements.

Solution

CNC machining with specialized tooling, heat treatment partnerships, and CMM inspection protocols.

Precision Manufacturing for

Critical Industries

From medical devices to aerospace components, our precision manufacturing serves industries where quality and reliability are non-negotiable.

Medical Devices

Surgical instruments, implants, diagnostic equipment

Electronics

Semiconductor housings, connectors, heat sinks

Automation

Robotics parts, actuators, precision assemblies

Get Your Custom

Manufacturing Quote Today

Upload your specifications and receive a detailed manufacturing quote with DFM analysis within 24 hours. Expert engineering support included.