Precision

CNC Machining

Solutions

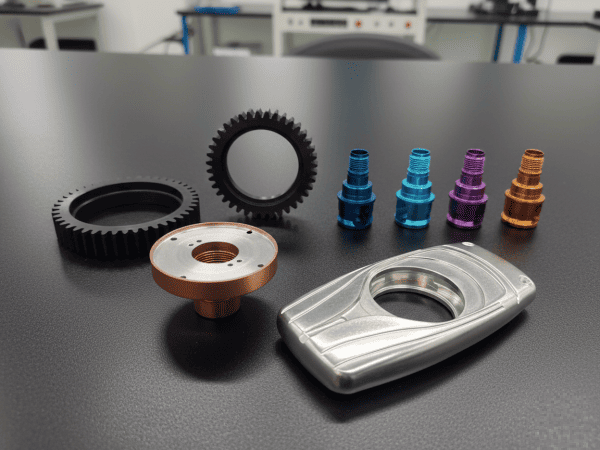

Master-level CNC milling, precision turning, EDM processing, and surface grinding for the most demanding applications with ±0.01mm tolerance capability.

Advanced Precision Machining

Master-level expertise in four critical precision machining technologies, delivering uncompromising quality for the most demanding applications.

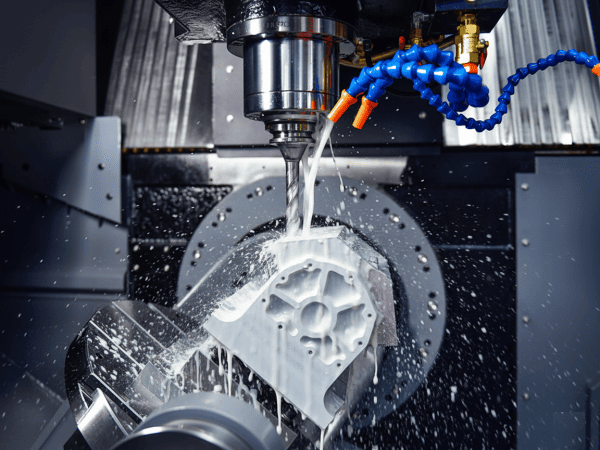

Precision CNC Milling

3-5 axis precision milling for complex geometries, prototypes, and production parts. Advanced CAM programming and high-speed machining for superior surface finishes.

Precision CNC Machining Tolerances

Our advanced four-technology precision machining platform delivers exceptional accuracy across multiple manufacturing processes, meeting the most stringent tolerance requirements.

| Manufacturing Process | Typical Tolerance | Best Tolerance |

|---|---|---|

|

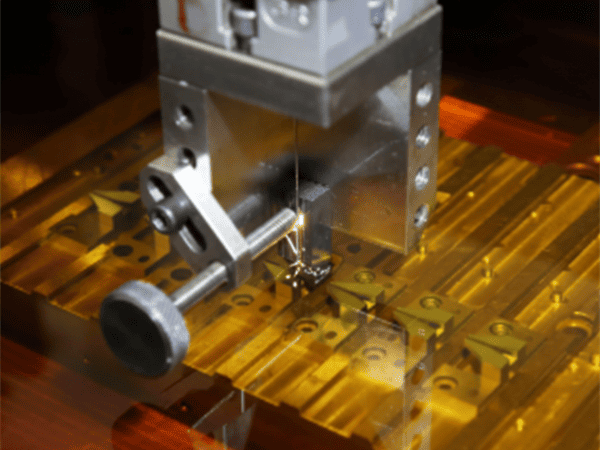

EDM (Electrical Discharge Machining)

Wire & Sinker EDM for complex geometries

|

±0.020mm | ±0.005mm |

|

Precision Grinding

Surface & cylindrical grinding operations

|

±0.005mm | ±0.002mm |

|

CNC Milling

3-5 axis precision milling operations

|

±0.020mm | ±0.005mm |

|

CNC Turning

Multi-axis turning & live tooling

|

±0.02mm | ±0.010mm |

ISO Certified Quality

All processes follow ISO 9001:2015 standards with full traceability and documentation.

CMM Inspection

Coordinate measuring machines ensure dimensional accuracy with detailed inspection reports.

First Article Approval

Complete dimensional verification and approval process before production runs.

Precision for Demanding Industries

Our four-technology precision machining platform serves the most demanding industries where accuracy, reliability, and superior surface finish are critical.

Medical Devices

Rehabilitation and surgical instruments with stringent surface finish requirements.

Electronics & Semiconductors

Precision housings, heat sinks, and micro-components for electronic assemblies.

Industrial Equipment

Heavy-duty components for industrial machinery and automation systems.

Automotive Performance

High-performance engine components and transmission parts for complex geometries.

Energy & Power Generation

Components for renewable energy and power systems with specialized requirements.

Microneedle Mold Inserts

Ultra-Precision Manufacturing

Combining CNC machining, EDM, and grinding technologies to achieve ±10μm overall tolerance and 5μm needle tip precision for medical device applications.

Presision CNC Machining

Initial rough and semi-finish operations to establish base geometry and critical features with ±15μm precision.

Wire EDM Processing

Rough cutting of complex needle matrix geometries and intricate channels with ±10μm accuracy.

Ultra-Precision Grinding

Final surface finishing and dimensional control achieving 5μm needle tip precision with Ra 0.4μm surface finish.

Comprehensive Resources for

Precision Machining

Access expert knowledge, technical guides, and manufacturing insights to optimize your precision parts production.

Technical Guides

Comprehensive manufacturing guides covering CNC machining, injection molding, and sheet metal fabrication best practices.

- Material Selection Guidelines

- Tolerance & Surface Finish Standards

- DFM Optimization Tips

CAD Tools & Templates

Download ready-to-use CAD templates, part libraries, and design tools to accelerate your product development process.

- Standard Part Libraries

- CAD File Templates

- Drawing Standards

Quality Certificates

Access our ISO certifications, quality standards documentation, and inspection reports to ensure compliance requirements.

- ISO 9001:2015 Certificate

- Material Test Reports

- Inspection Procedures

Get Your Custom Parts

Manufactured Today

Upload your CAD files and receive a detailed quote with DFM analysis within 24 hours. From prototypes to production, we deliver precision parts worldwide.