Swiss

Machining

Excellence

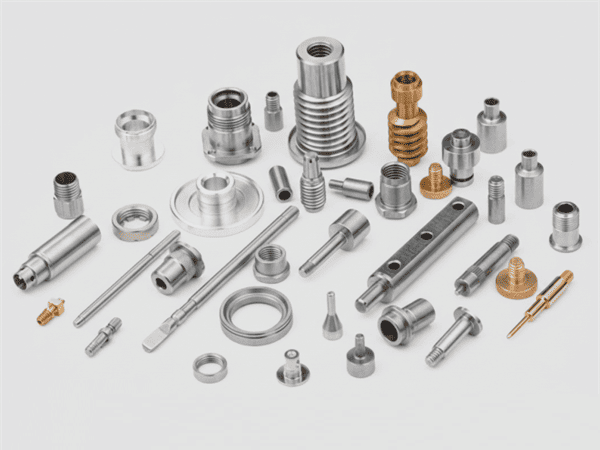

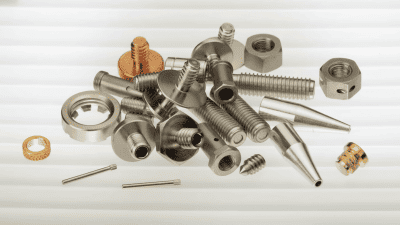

Specialized in high-precision small parts manufacturing with Swiss-type CNC machines. Perfect for complex geometries shafts and pins.

Why Choose Swiss Machining?

Swiss-type CNC machines excel at manufacturing small, complex parts with exceptional precision and surface finish, making them ideal for critical applications in medical, aerospace, and electronics industries.

Superior Precision & Surface Finish

Guide bushing support ensures minimal deflection, achieving tolerances as tight as ±0.01mm with Ra 0.8μm surface quality.

Complete Machining in Single Setup

Simultaneous front and back operations with multi-axis capability enable complex geometries and reduce cycle times significantly.

Cost-Effective High Volume Production

Automated bar feeding and consistent quality across large volumes with minimal secondary operations and high material utilization.

Perfect for Critical Applications

Swiss machining excels in industries requiring high precision, complex geometries, and superior surface finishes on small parts.

Medical Devices

Surgical instruments, implant components, dental tools, and precision medical hardware requiring biocompatible materials and ultra-tight tolerances.

Electronics & Semiconductors

Connector pins, sensor housings, RF components, and precision electronic hardware with complex geometries and fine surface finishes.

Precision Instruments

Watch components, optical parts, measuring instruments, and calibration standards requiring exceptional dimensional accuracy.

Automotive & Aerospace

Fuel injection components, sensor parts, fasteners, and critical safety components with stringent quality requirements.

Technical Capabilities

Our Swiss CNC machines deliver exceptional precision and versatility for demanding small part manufacturing requirements.

Machine Specifications

Materials We Machine

Key Features

Resources for Swiss Machining

Expert insights and practical guides to help you optimize your Swiss machining projects for better performance and cost efficiency.

Swiss Machining vs Traditional CNC: When to Choose Each Method

Understand the key differences between Swiss-type lathes and conventional CNC machines, including optimal part geometries, tolerances, and cost considerations.

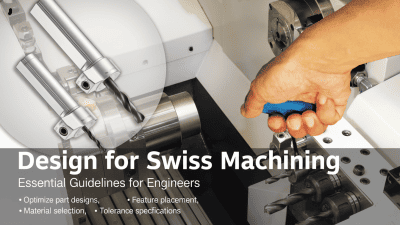

Design for Swiss Machining: Essential Guidelines for Engineers

Learn how to optimize your part designs for Swiss machining efficiency, including feature placement, material selection, and tolerance specifications.

Material Selection for Swiss Machining: Properties and Applications

Comprehensive guide to choosing the right materials for Swiss machining projects, covering machinability, surface finishes, and industry applications.

Ready for Precision

Swiss Machining?

Upload your drawings and specifications to receive a detailed quote with DFM analysis for your Swiss machining project within 24 hours.