Custom

Injection Molding

Solutions

From prototype molds to high-volume production, Xu Feng delivers precision plastic components with complete mold design, DFM analysis, and quality assurance.

Complete Manufacturing Services

From rapid prototyping to high-volume production, our injection molding facility delivers custom plastic components with precision engineering and quality assurance.

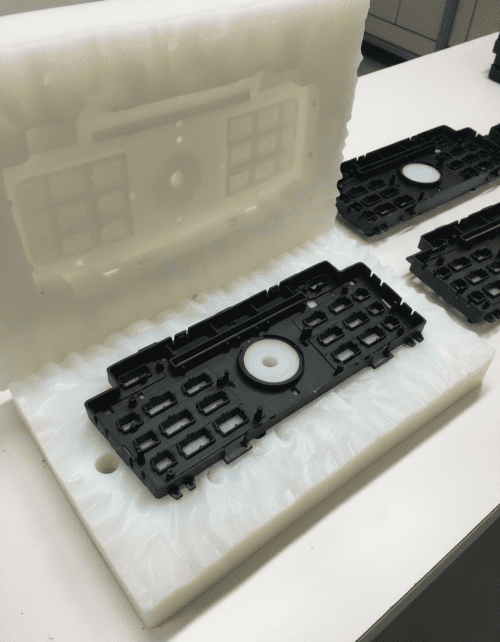

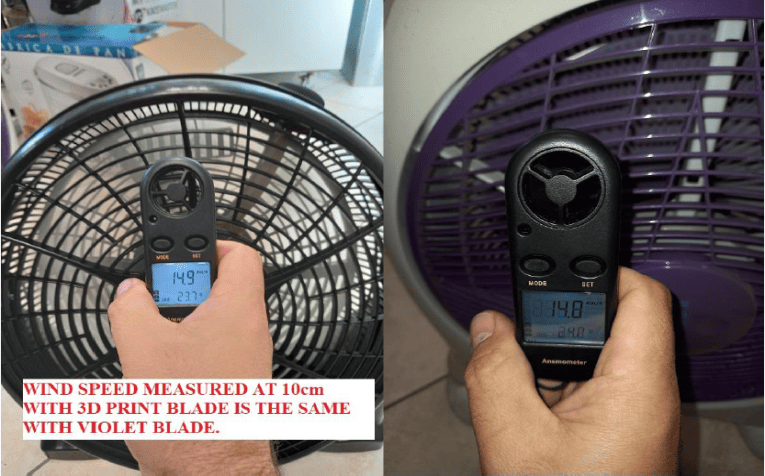

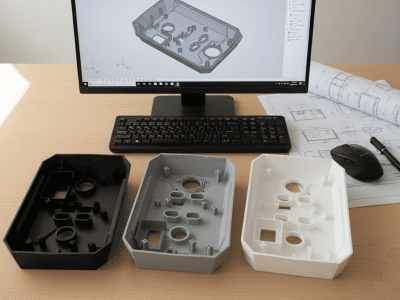

Rapid Prototyping

3D printing and bridge tooling to validate design concepts and functionality before production tooling.

- 5-7 days delivery

- Multiple iterations support

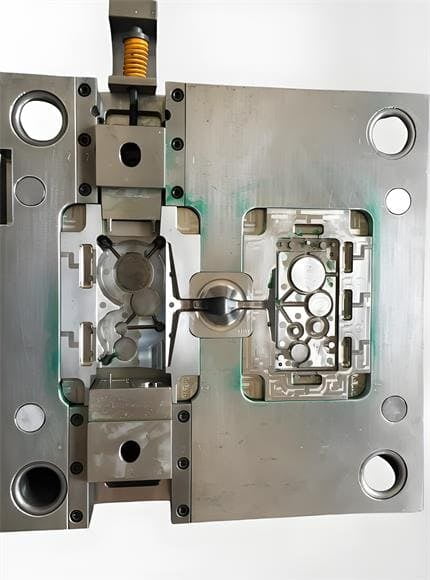

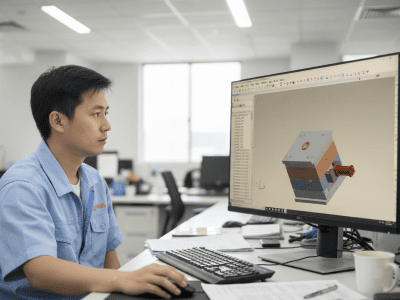

Mold Design Service

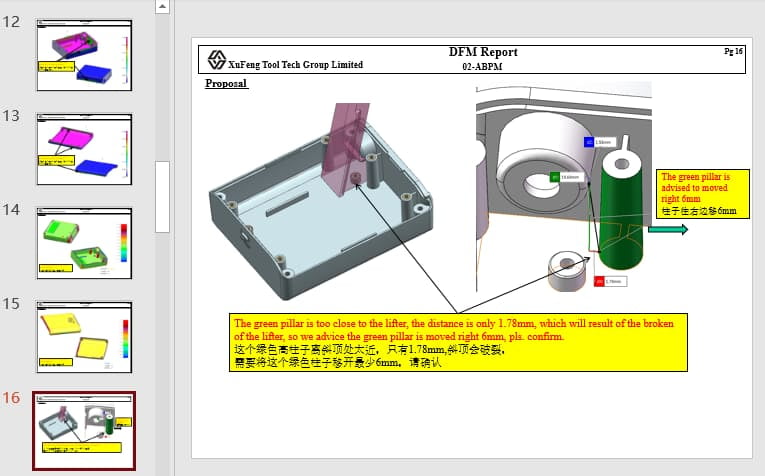

Advanced CAD-based mold design with DFM analysis, flow simulation, and cooling system optimization.

- DFM analysis included

- Mold flow simulation

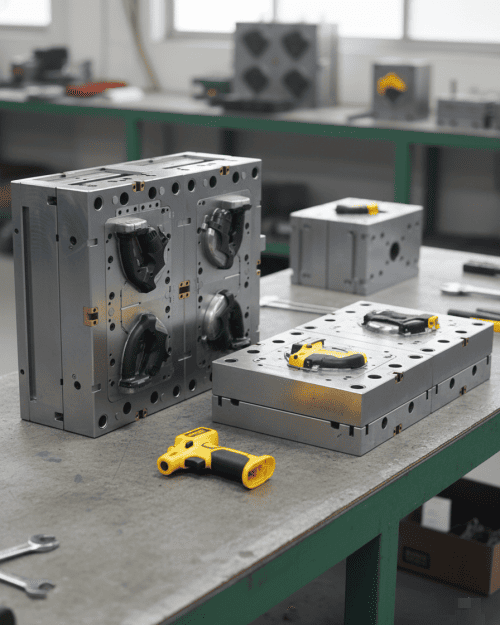

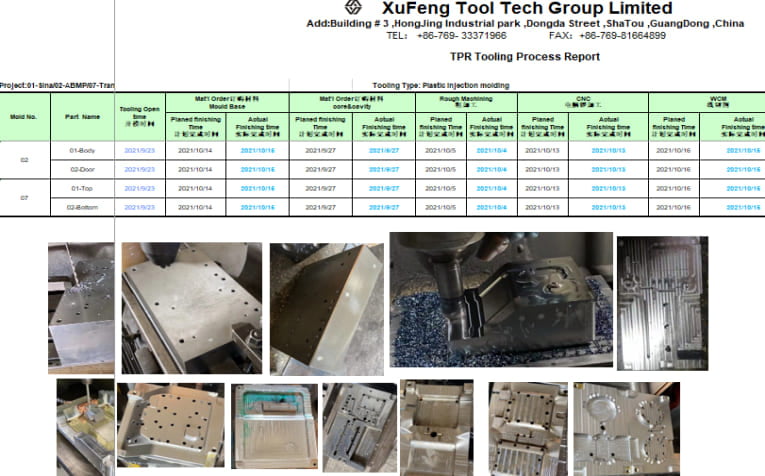

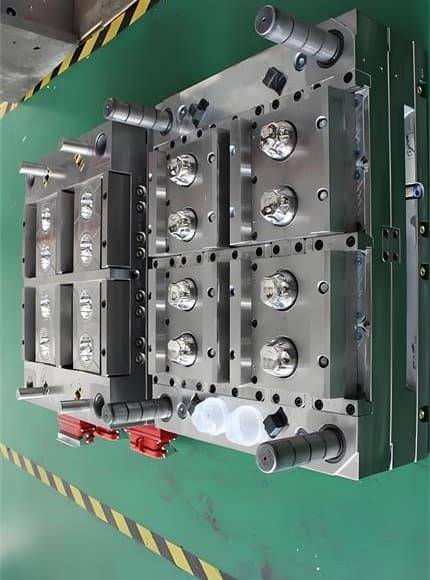

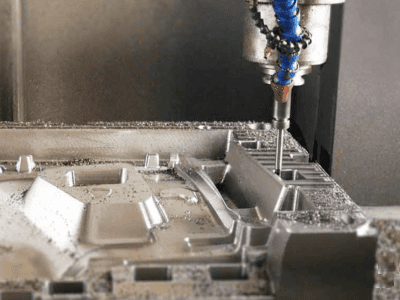

Mold Making & Tooling

Precision mold manufacturing using CNC machining and EDM technologies for millions of cycles.

- Multi-cavity molds

- High-precision tooling

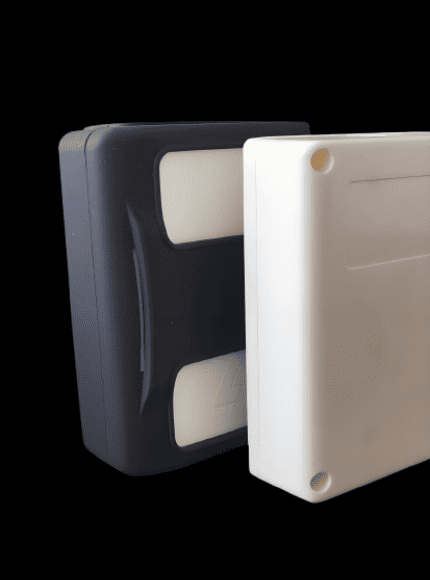

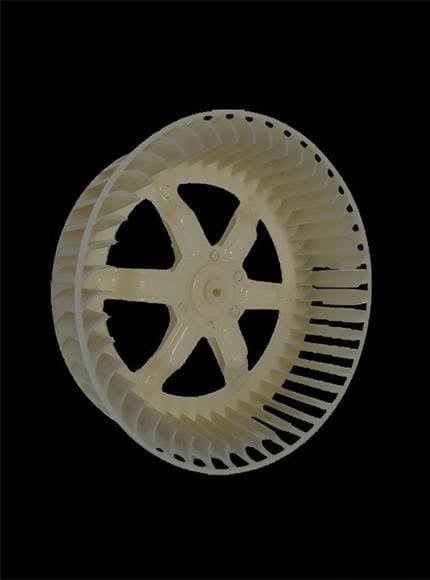

Injection Molding

High-volume production with wide material selection by using multi-cavity molds and hot runner systems.

- 500-1M+ units capacity

- Medical-grade materials

Post-Processing

Comprehensive finishing services including trimming, painting, laser etching, and ultrasonic welding.

- Ultrasonic Welding

- Custom printing & painting

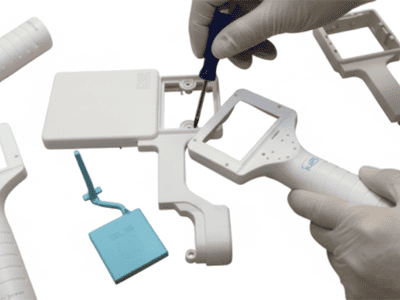

Product Assembly

Complete assembly services with quality testing, packaging, and logistics support for finished products.

- Quality testing included

- Custom packaging

Advanced Manufacturing Capabilities

Plastic Injection Molding

High-volume production of precision plastic parts using advanced injection molding technology. From prototyping to mass production, we deliver consistent quality with tight tolerances and excellent surface finishes.

Machine Capacity

- Clamping Force: 50-1000 tons

- Shot Size: Up to 2000g

- Part Size: 1mm - 800mm

Quality Standards

- Tolerance: ±0.05mm

- Surface Finish: Ra 0.8-3.2μm

- Wall Thickness: 0.3-10mm

Common Materials

Injection Molding Process

From initial design review to final delivery, our systematic 8-step approach ensures optimal part quality and production efficiency.

Upload Your Files

Submit your design files and specifications through our secure platform for instant analysis.

DFM Analysis

Our engineers review your design for manufacturability and provide optimization recommendations.

Tooling Setup

Precision mold fabrication or CNC programming based on your specific requirements.

First Article

Sample production and comprehensive inspection to validate specifications before full production.

Production Run

High-volume manufacturing with continuous quality monitoring and process control.

Quality Control

Statistical process control and final inspection with detailed quality reports.

Reorder Parts

Enable fast reorders at any time by using molds already stored in our mold library.

Ready to Start?

Comprehensive Plastic Material Library

We offer a wide selection of 50+ thermoplastic and thermoset materials, each carefully selected for its specific performance characteristics and suitability for various applications.

Engineering Plastics

High Performance Injection Molding

General Engineering

- ABS (High impact strength)

- PC (Polycarbonate)

- Nylon PA6/PA66

- POM (Delrin/Acetal)

High Performance

- PEEK (Aerospace grade)

- PEI (Ultem)

- PTFE (Teflon)

- PPS (Fortron)

Reinforced Grades

- Glass Fiber Reinforced

- Carbon Fiber Filled

- Mineral Filled

- Conductive Compounds

Specialty Compounds

- TPU (Thermoplastic PU)

- TPE (Thermoplastic Elastomer)

- LSR (Liquid Silicone Rubber)

- Bio-based Polymers

Standard & Specialty Grades

Cost-Effective & Certified Materials

Standard Plastics

- PP (Polypropylene)

- PE (Polyethylene)

- PS (Polystyrene)

- PMMA (Acrylic)

Medical Grade

- USP Class VI Certified

- ISO 10993 Biocompatible

- Gamma Sterilizable

- Implantable Grade

Food Grade

- FDA 21 CFR 177 Compliant

- EU 10/2011 Regulation

- NSF 51 Certified

- Dishwasher Safe

Flame Retardant

- UL94 V-0 Rated

- Halogen-Free Options

- Low Smoke/Toxicity

- Electrical Insulation

Your Injection Molding

Material Guide

Choose the perfect plastic material for your injection molding project. Our comprehensive guide covers material properties, processing requirements, and application-specific recommendations to optimize performance and cost-effectiveness.

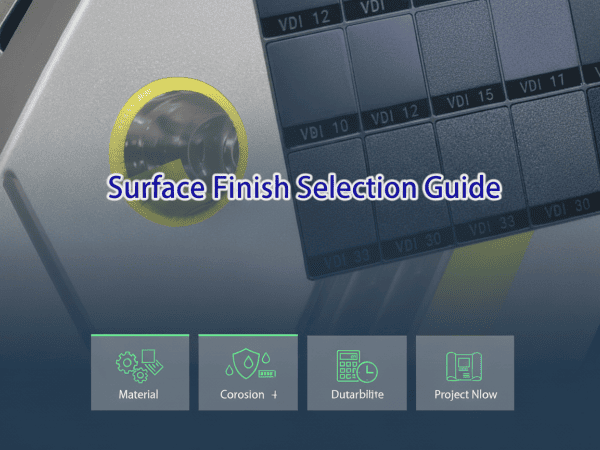

Injection Mold Surface Finishes

Advanced surface finishing techniques to enhance functionality, aesthetics, and performance of your injection molded components.

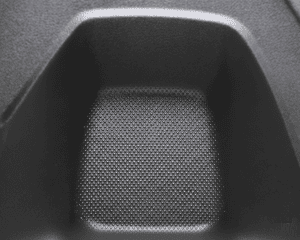

Mold Texturing

Chemical etching and EDM texturing create precise surface patterns for improved grip, aesthetics, and functionality.

- VDI/SPI standards

- Custom patterns available

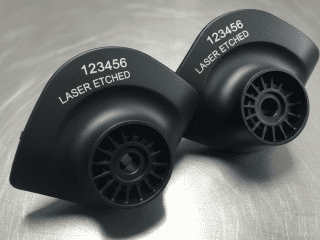

Laser Engraving

Precision laser engraving directly onto mold surfaces for permanent marking, logos, and detailed graphics.

- High-resolution details

- Permanent marking

Printing

Pad printing, screen printing, and digital printing solutions for branding and functional markings on molded parts.

- Multi-color capability

- UV-resistant inks

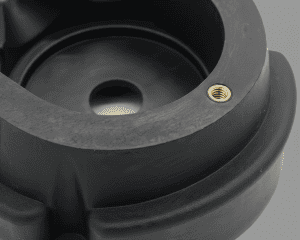

Metal Insert

Insert molding with threaded inserts, bushings, and metal components for enhanced strength and functionality.

- Threaded inserts

- Custom metal parts

Surface Finish Selection Guide

Choose the perfect surface finish for your parts with our comprehensive selection guide. From functional coatings to aesthetic treatments, we help you match the right finish to your application requirements.

Quality and Validation Offerings

Comprehensive quality validation reports and analysis to ensure your parts meet the highest manufacturing standards.

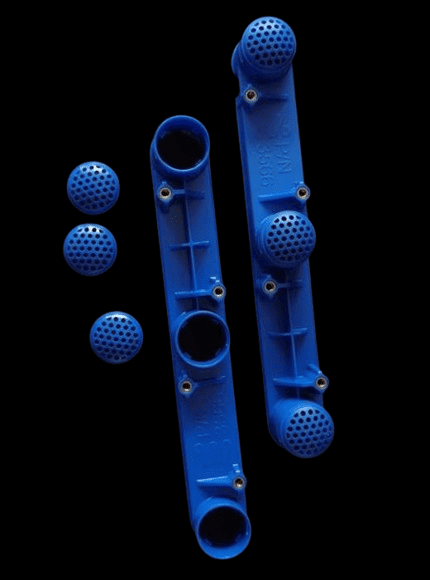

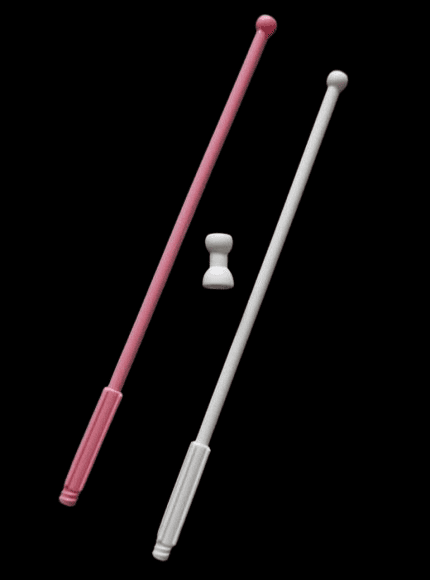

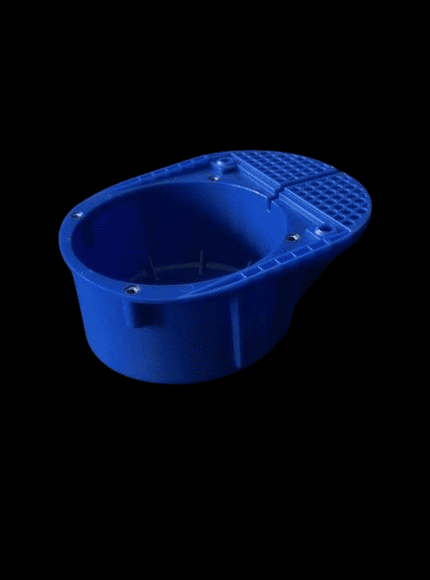

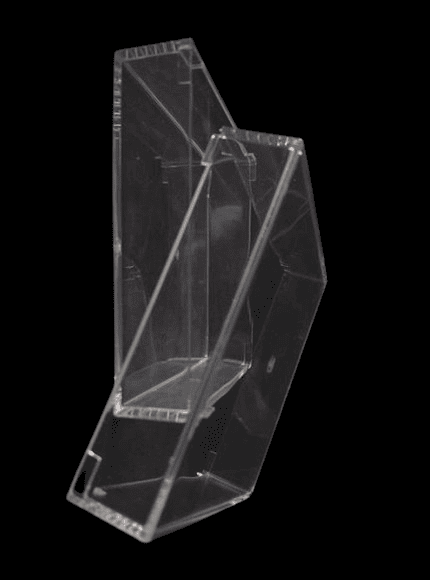

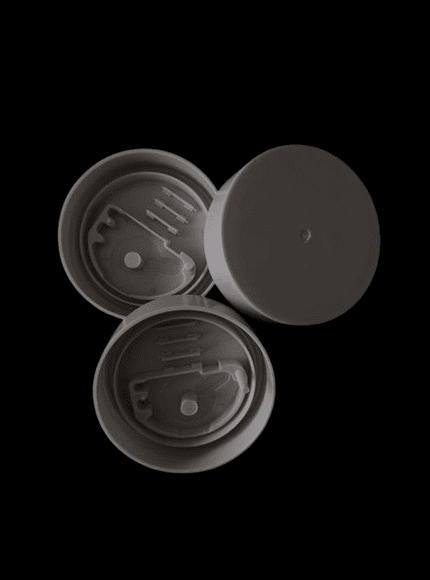

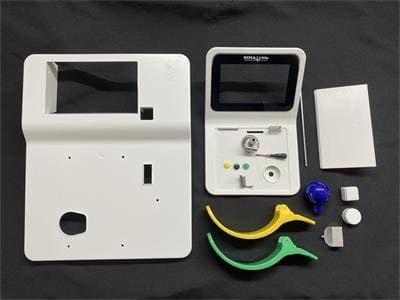

Injection Molding Parts and Tools Made By Xu Feng

Precision injection molding solutions from prototype to mass production with advanced tooling and quality assurance.

Frequently Asked Questions

Get expert answers to common injection molding questions from our engineering team.

Why is injection mold tooling expensive, and how can the upfront cost be reduced?

Why is injection mold tooling expensive, and how can the upfront cost be reduced?

Injection molds are a one-time engineering investment. The cost mainly comes from:

- Mold material (aluminum, pre-hardened steel, hardened steel)

- Precision machining and assembly

- Cooling, ejection, and mold life design

How to reduce risk and upfront cost:

For early-stage projects, rapid tooling can be used for prototyping or small batches. Once the design and demand are confirmed, the project can transition to a full production mold, optimizing long-term cost.

What is the minimum order quantity (MOQ) for injection molding?

What is the minimum order quantity (MOQ) for injection molding?

MOQ is not fixed and depends on:

- Mold type (rapid tooling vs. production tooling)

- Plastic material (commodity, engineering, or high-performance resin)

- Part size and cycle time

Prototype / pilot runs:

100-500 pcs

Production runs:

1,000+ pcs

for better unit pricing

For low-volume demand: A bridge production approach is often the most cost-effective solution.

How are dimensional accuracy and consistency ensured in injection molding?

How are dimensional accuracy and consistency ensured in injection molding?

Dimensional control is achieved through mold design and process control, including:

- Accurate shrinkage compensation

- Optimized cooling layout

- Stable molding parameters and in-process inspection

Typical tolerances:

Expert Recommendation: For functional or assembly-critical features, early DFM review is strongly recommended.

Have More Questions?

Our engineering team is ready to discuss your specific injection molding requirements and provide expert guidance.