Custom

Mold Making

Solutions

From prototype molds to high-volume production tooling, Xu Feng creates custom injection molds with tailored functionality and lifespan designed to meet your specific requirements and production cycles.

Professional Injection Mold Solutions

Comprehensive injection mold manufacturing from rapid prototyping to high-volume production with advanced design optimization and precision tooling.

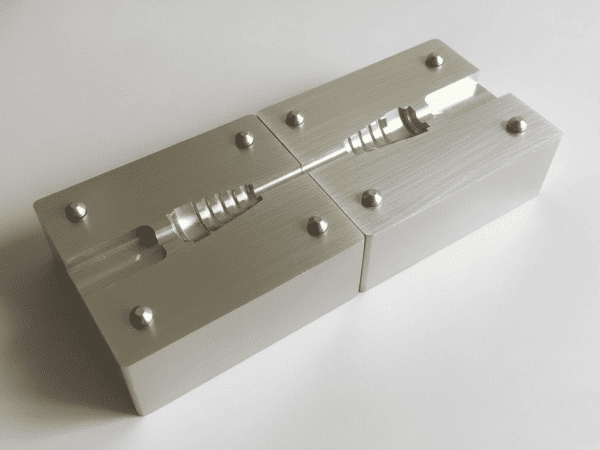

Single Cavity Mold

- Lower initial investment

- Faster mold development

- Easy maintenance

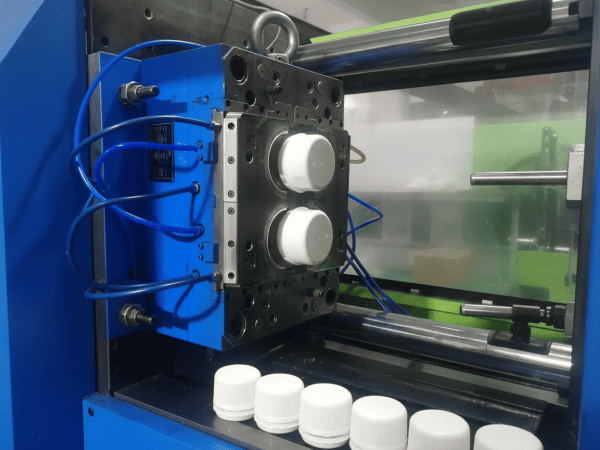

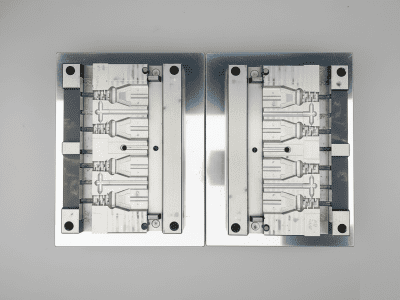

Multi Cavity Mold

- Higher production output

- Lower cost per part

- Optimized cycle time

Rapid Mold

- 7-15 day delivery

- Aluminum construction

- Prototype validation

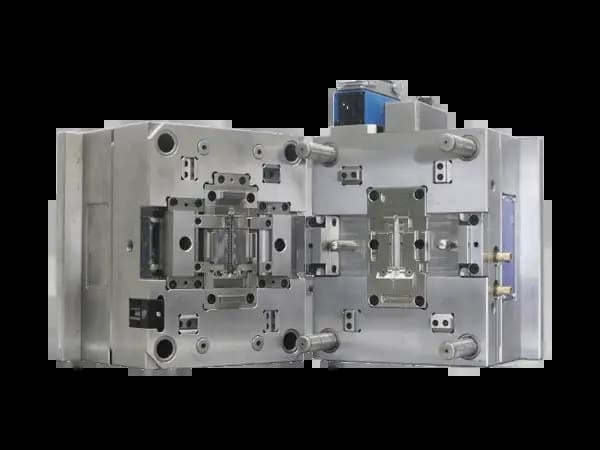

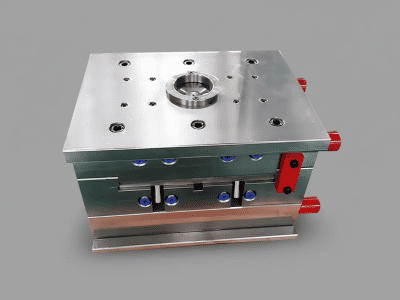

Production Mold

- P20, H13, S136 steel

- Hot runner systems

- 1M+ shot lifecycle

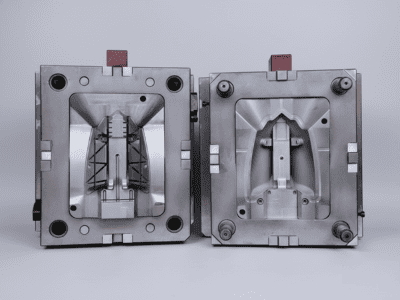

Advanced Tooling & Mold Solutions

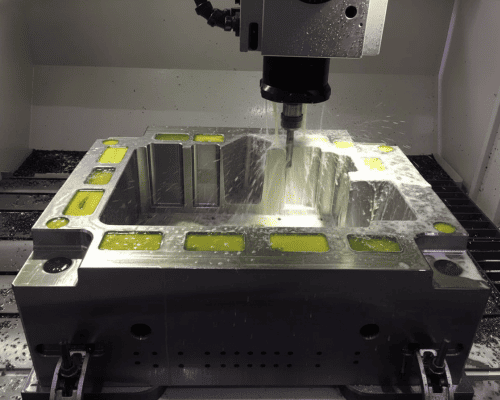

From concept to production-ready tooling, our precision mold manufacturing combines advanced CNC technology with expert craftsmanship to deliver injection molds, stamping dies, and custom tooling that meet the highest quality standards.

Mold Manufacturing Capabilities

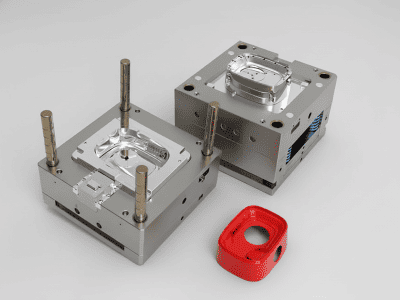

Injection Molds

Single & multi-cavity molds for thermoplastics, overmolding, and insert molding applications

Mold Manufacturing

Complete mold fabrication services from roughing to precision finishing for injection molding applications

Custom Tooling

Specialized fixtures, jigs, gauges, and production tooling designed for your specific manufacturing needs

Manufacturing Process

Materials for Injection Mold

From rapid prototyping to high-volume production tooling, we select the optimal mold materials based on your specific requirements for durability, precision, and cost-effectiveness.

Silicone Molds

Flexible silicone molds for rapid prototyping and low-volume production with complex geometries. Perfect for vacuum casting and intricate part designs.

Key Features

- Vacuum casting compatible

- Complex undercuts possible

- Fast turnaround time

Specifications

- 10-50 parts typical

- Shore A 20-40

- ±0.2mm tolerance

| Mold Class | Purpose | Lifetime Cycles | Material | Hardness | Wear Resistance |

|---|---|---|---|---|---|

| Class 101 | Prototype & Testing | 500-1,000 | Aluminum 7075 | HRC 15-20 | Low |

| Class 102 | Low Volume Production | 10,000-25,000 | P20 Steel | HRC 28-32 | Medium |

| Class 103 | Medium Volume Production | 100,000-500,000 | H13 Tool Steel | HRC 48-52 | High |

| Class 104 | High Volume Production | 500,000-1,000,000 | S136 Stainless Steel | HRC 50-54 | Very High |

| Class 105 | Ultra High Volume | 1,000,000+ | Beryllium Copper | HRC 38-42 | Excellent |

Resources for Mold Making

Expert insights, technical guides, and industry best practices to help you optimize your mold design and manufacturing process.

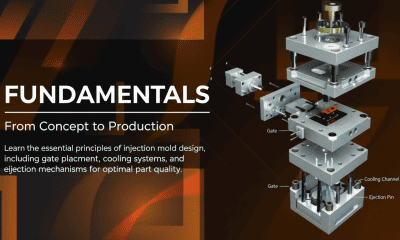

Injection Mold Design Fundamentals: From Concept to Production

Learn the essential principles of injection mold design, including gate placement, cooling systems, and ejection mechanisms for optimal part quality.

Material Selection Guide: Choosing the Right Plastic for Your Mold

Comprehensive guide to plastic materials for injection molding, covering properties, applications, and cost considerations for ABS, PC, PP, and more.

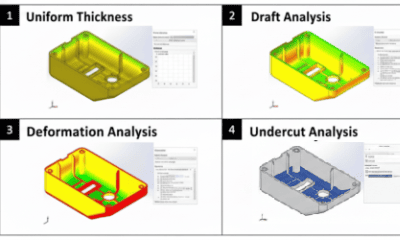

DFM Optimization: Reducing Costs and Lead Times in Mold Manufacturing

Practical Design for Manufacturing strategies to optimize your parts for injection molding, including draft angles, wall thickness, and undercuts.

Start Your Rapid

Mold Development

Upload your part design and receive a comprehensive mold quote with DFM analysis, timeline, and cost breakdown within 24 hours.