Plastic

Injection Molding

Solutions

From prototype molding to high-volume production, Xu Feng delivers custom plastic injection molding within 2 weeks.

What is Plastic Injection Molding?

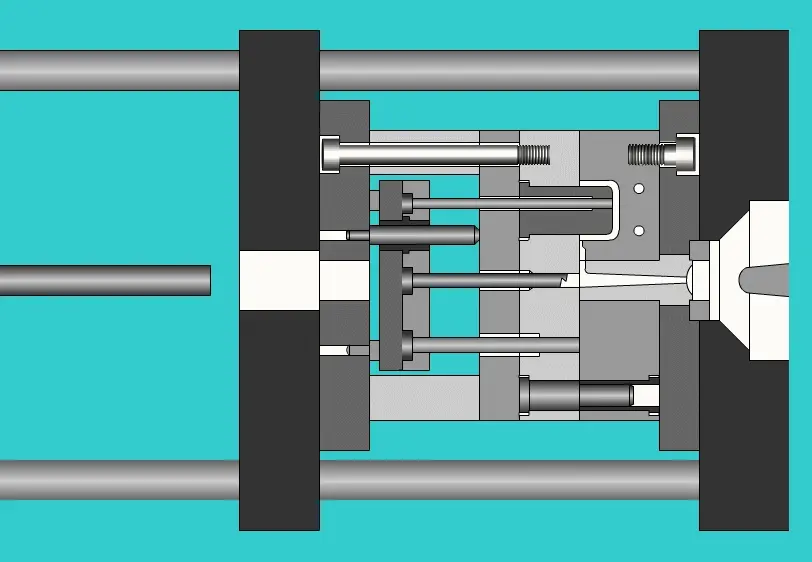

Plastic injection molding is a manufacturing process where molten plastic material is injected into a custom-designed mold cavity under high pressure. At Xu Feng, we deliver everything from prototype tooling to high-volume production runs with consistent quality.

Fast Production

Rapid cycle times for high-volume manufacturing

High Precision

Tight tolerances and consistent quality

Advanced Injection Molding Technologies

Leveraging state-of-the-art injection molding equipment and expertise to deliver precision plastic components from prototype to high-volume production.

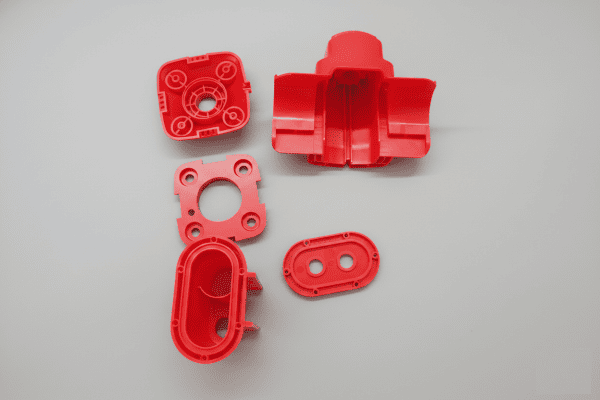

Multi-Shot Molding

Advanced multi-shot injection molding technology combining different materials and colors in a single molding cycle. Create complex parts with multiple hardness levels, colors, and material properties without assembly.

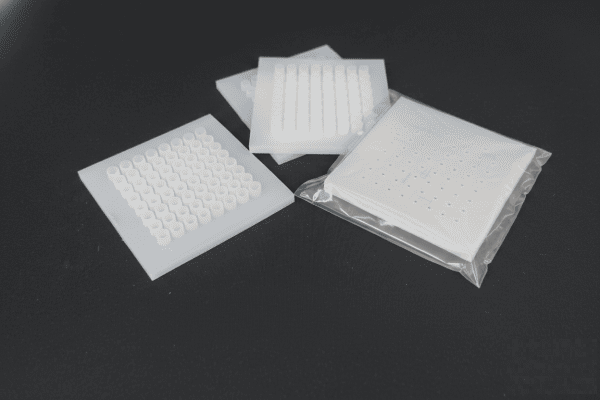

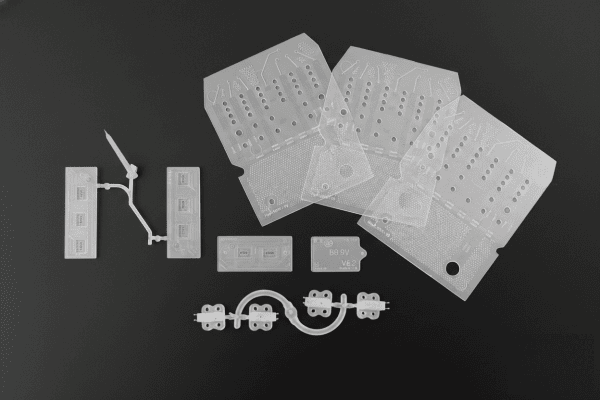

Micro Injection Molding

Precision micro injection molding for ultra-small components with shot weights from 0.001g to 1g. Specialized equipment and cleanroom environment for medical, electronics, and micro-mechanical applications.

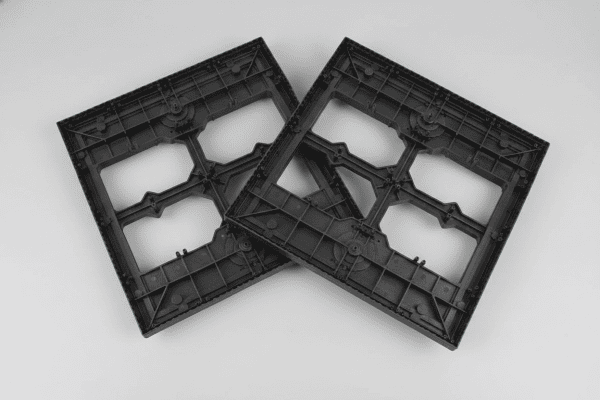

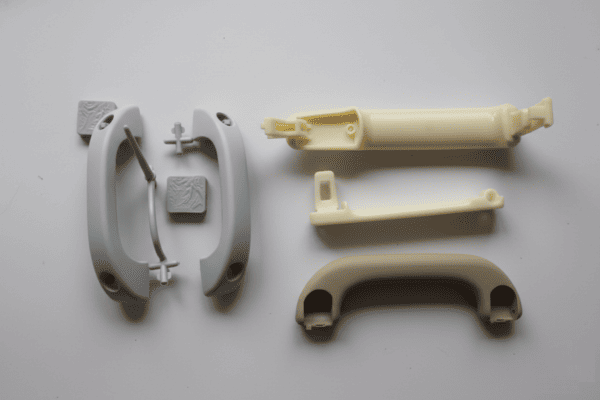

Large Part Molding

High-tonnage injection molding for large plastic components up to 2000 tons clamping force. Specialized in automotive panels, industrial housings, and large consumer products with consistent quality across large surfaces.

Thin-Wall Molding

High-speed thin-wall injection molding for lightweight components with wall thickness down to 0.3mm. Optimized for packaging applications, electronics housings, and weight-critical automotive components.

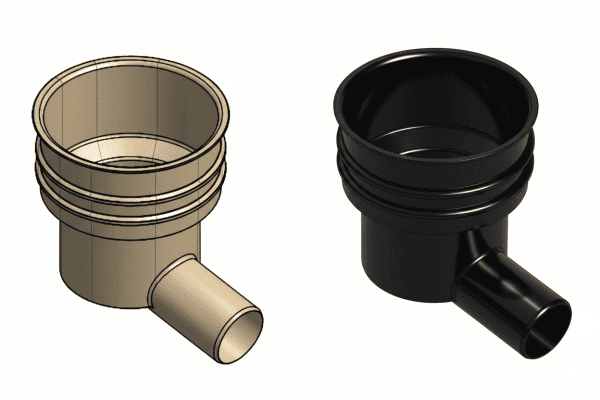

Gas-Assisted Injection Molding

Advanced gas-assisted injection molding using nitrogen gas to create hollow sections, reduce material usage, and eliminate sink marks. Ideal for thick-walled parts requiring structural strength with weight reduction.

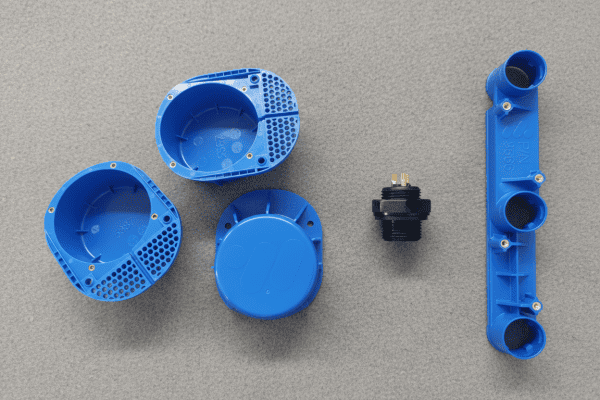

Insert Molding

Precision insert molding combining metal components with plastic in a single operation. Perfect for electrical connectors, threaded inserts, and complex assemblies requiring strong mechanical bonds between materials.

Advanced Equipment & Technology

Engineering-Grade Materials

From standard engineering plastics to high-performance polymers, we select the optimal material for your application requirements.

Rigid Plastic Materials

High-strength thermoplastics ideal for structural components, housings, and precision parts requiring dimensional stability and durability.

High-Performance Polymers

- PEEK - Aerospace & medical applications

- PPS - Superior chemical resistance

- PTFE - Ultra-low friction coating

- LCP - High-frequency electronics

Medical Grade Materials

- USP Class VI certified materials

- ISO 10993 biocompatible grades

- Sterilization compatible polymers

- ISO13485 material options

Reinforced Composites

- Glass fiber reinforced grades

- Carbon fiber filled compounds

- Mineral filled enhanced strength

- Flame retardant certified options

Need a Specific Material?

Custom material selection and testing available for specialized applications. Our engineering team will help you choose the optimal material for your performance requirements.

Request Material ConsultationPlastic Injection Molding Finishes

Achieve the perfect surface finish for your injection molded parts with our comprehensive range of finishing options and post-processing capabilities.

Direct Coloring

Integrate color directly into the molding process using masterbatch or liquid colorants for consistent, fade-resistant results throughout the part volume.

- Custom color matching (RAL, Pantone)

- UV-stable pigments available

- No secondary painting required

- Cost-effective for high volumes

Our Injection Molding Process

From initial design review to final production, our systematic approach ensures optimal results at every stage.

Design Review & DFM Analysis

Engineers analyze your design for moldability, suggesting optimizations for better quality and cost efficiency.

Mold Design & Manufacturing

Custom mold design with advanced CAD/CAM systems, followed by precision machining using in-house tooling.

First Article Inspection

Complete dimensional inspection and material testing to ensure parts meet all specifications before production.

Production & Quality Control

Automated production with continuous monitoring, statistical process control, and final inspection before packaging.

Industry

Medical Devices

Product

Plastic Housing

Capabilities Leveraged

Challenge

Find a manufacturing partner who can provide the full capabilities and get the design from prototype to production.

Result

Finish the process from prototype to production in less than half a year.

Ready to Start Your

Plastic Injection Project?

Upload your CAD files and specifications to receive a detailed quote with DFM analysis within 24 hours.