Rapid Tooling

Solutions

Accelerate your product development with our rapid tooling services. From concept to market in weeks, not months. Perfect for prototyping, low-volume production, and meeting today's personalized manufacturing demands.

Xu Feng's

Rapid Tooling Services

Accelerate your product development with our advanced rapid tooling solutions. From prototype to production, we deliver precision tooling with dramatically reduced lead times while maintaining the highest quality standards.

Ultra-Fast Turnaround

5-10 day tooling delivery vs 6-8 weeks traditional lead times

Cost-Effective Solutions

60% lower initial investment for low to medium volume production

Production-Grade Quality

±0.05mm precision with full material compatibility

Rapid Tooling Capabilities

Comprehensive rapid tooling solutions across multiple manufacturing processes, designed to accelerate your product development cycle.

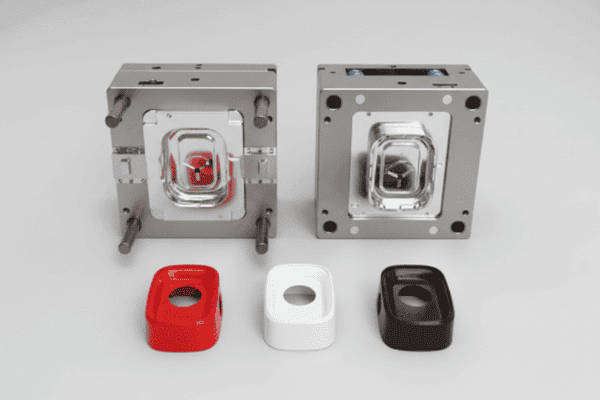

Fast Mold Tooling Making

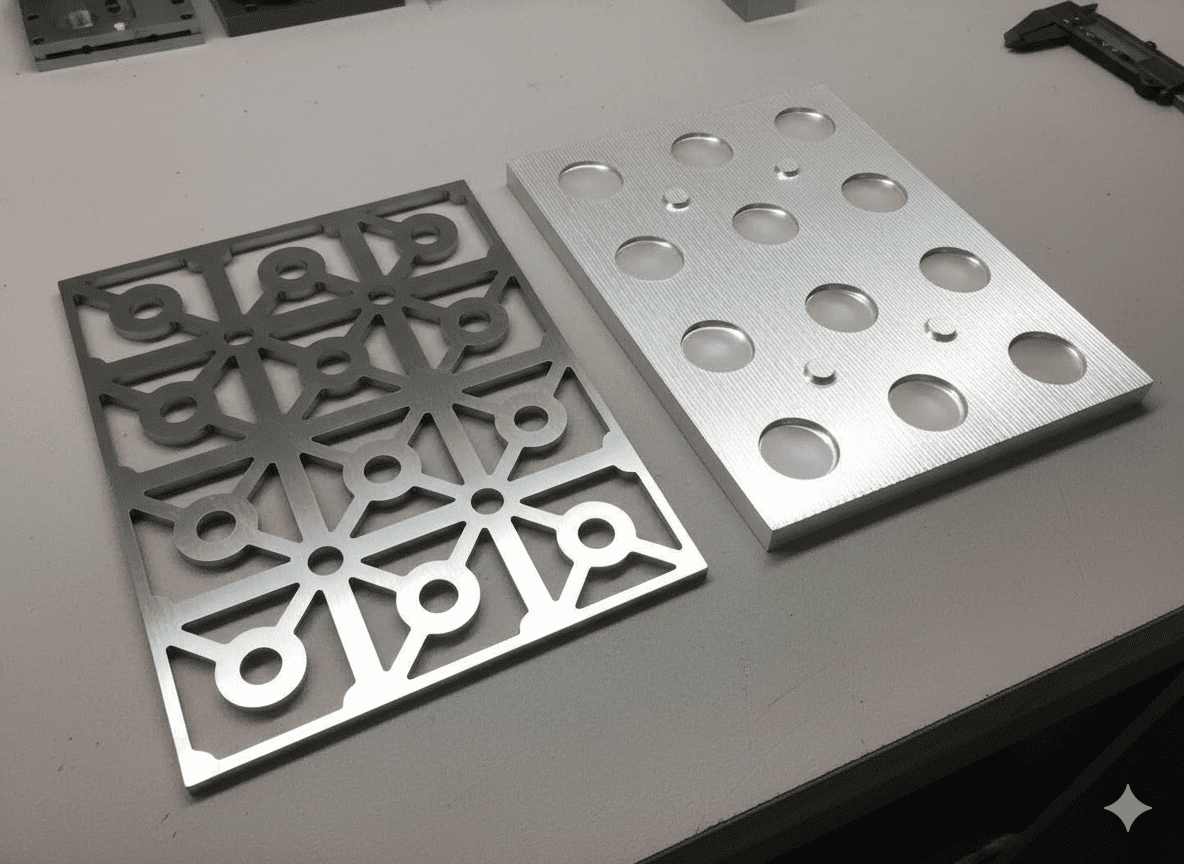

Rapid aluminum and steel mold production using advanced CNC machining technology. From prototype to production-ready tooling in record time with precision engineering.

Low Volume Injection Molding

Cost-effective small batch plastic part production perfect for market testing, bridge production, and specialized applications. Quality parts without high-volume commitments.

Advanced Technologies

5-Axis CNC

High-speed machining for complex tool geometries

EDM Processing

Wire and sinker EDM for intricate features

3D Printing

Additive manufacturing for complex inserts

Quality Systems

CMM inspection and process validation

Rapid Tooling Material Options

Choose the optimal mold material based on your production volume, precision requirements, and timeline constraints.

| Specifications |

Silicone Mold

Rapid Prototyping

|

Aluminium Mold

Bridge Tooling

|

Steel Mold

Short-Run Production

|

|---|---|---|---|

| Production Volume | 5-100 parts | 100-3,000 parts | 500-10,000 parts |

| Tooling Lead Time | 3-7 days | 2-4 weeks | 3-5 weeks |

| Surface Finish |

|

|

|

| Dimensional Accuracy | ±0.3~0.5mm | ±0.05~0.1mm | ±0.03~0.08mm |

| Material Compatibility | PU resins (ABS-like, PC-like, rubber-like) | Real thermoplastics (ABS, PC, PA, PP, etc.) | All Thermoplastics& engineering plastics |

| Tooling Cost | Lowest | Moderate | Higher |

| Ideal Applications | Concept validation Design iteration |

Market testing Pre-production |

Pilot production Limited series |

Choose Silicone

For ultra-fast prototyping, design validation, and complex geometries where speed and flexibility are critical.

Choose Aluminium

For bridge tooling, market testing, and medium-volume production with balanced cost and quality.

Choose Steel

For high-precision rapid tooling, pilot production, and short-run manufacturing with maximum durability.

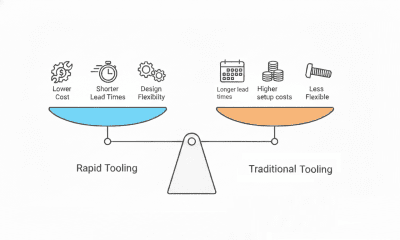

Benefits of Rapid Tooling

Accelerate your product development with our advanced rapid tooling solutions designed for speed, precision, and cost-effectiveness.

Lightning Fast Delivery

Reduce tooling lead times from weeks to days. Our rapid tooling process delivers functional prototypes and low-volume production parts in 5-10 days.

Cost-Effective Solution

Significantly lower upfront investment compared to traditional tooling. Perfect for prototypes, bridge tooling, and low to medium volume production runs.

Design Flexibility

Easy design iterations and modifications without massive cost penalties. Test multiple design variants quickly before committing to production tooling.

Production-Grade Quality

Achieve tight tolerances and excellent surface finishes. Our rapid tooling produces parts that meet the same quality standards as traditional tooling methods.

Risk Mitigation

Validate your design and manufacturing process before investing in expensive production tooling. Minimize project risks and avoid costly design changes.

Faster Time-to-Market

Launch products faster and capture market opportunities. Rapid tooling accelerates your entire product development cycle from concept to market.

Resources for Rapid Tooling

Expert insights and practical guides to help you optimize your rapid tooling projects and manufacturing decisions.

Rapid Tooling vs Traditional Tooling: Complete Cost & Time Analysis

Discover when rapid tooling delivers the best ROI for your project. Compare lead times, costs, and quality outcomes across different production volumes.

Material Selection Guide for Rapid Tooling Applications

Learn how to choose the right materials for rapid tooling based on part geometry, production volume, and performance requirements.

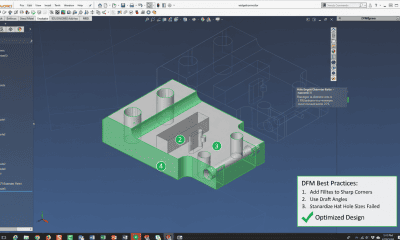

DFM Best Practices: Optimizing Designs for Rapid Tooling Success

Essential design guidelines to reduce lead times, minimize costs, and ensure manufacturability in rapid tooling projects.

Need Expert Guidance?

Get personalized recommendations for your rapid tooling project. Our engineering team provides free DFM analysis and manufacturing consultation.

Schedule Consultation