Silicon & Rubber

Molding Services

Precision liquid silicone rubber (LSR) and solid rubber molding for medical devices, automotive, and industrial applications. From prototypes to high-volume production with exceptional quality control.

Precision Silicon & Rubber Molding Solutions

Our state-of-the-art silicon and rubber molding capabilities deliver high-quality elastomer parts for demanding applications. We specialize in both liquid silicone rubber (LSR) and conventional rubber molding processes.

LSR Molding

Liquid silicone rubber for medical and food-grade applications

Solid Rubber

Conventional rubber molding for industrial applications

Complete Silicon & Rubber Manufacturing Solutions

From material selection to final inspection, we provide comprehensive molding services with advanced equipment and quality control systems.

LSR Injection Molding

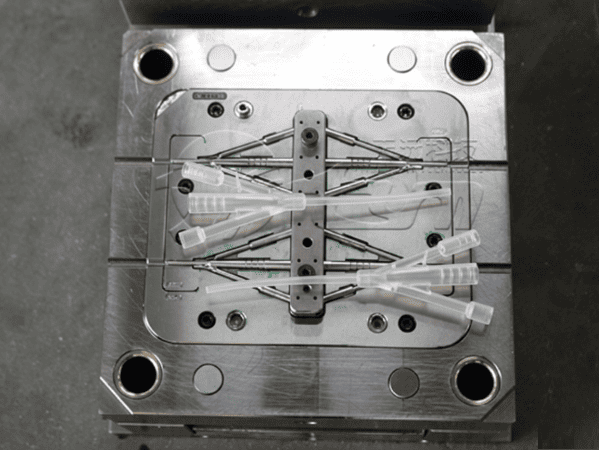

Liquid silicone rubber molding with precise temperature and pressure control for consistent quality. Our advanced LSR systems ensure optimal material flow and cure characteristics for medical-grade applications.

Material Options

We work with a wide range of silicon and rubber materials to meet your specific application requirements.

Silicone Materials

Liquid Silicone Rubber (LSR)

Medical and food grade, excellent biocompatibility

High Temperature Silicone

Excellent thermal stability up to 300°C

Conductive Silicone

Electrically conductive for EMI shielding applications

Rubber Materials

Natural Rubber (NR)

Excellent elasticity and tear resistance

EPDM Rubber

Weather resistant, excellent ozone resistance

NBR (Nitrile)

Oil and fuel resistant for automotive applications

Case Studies

Real-world examples of our silicon and rubber molding capabilities across various industries.

Medical Device Silicone Bulb

Challenge

A medical device manufacturer needed medical-grade silicone bulb with assembly requirements and precise sealing performance for critical applications.

Solution

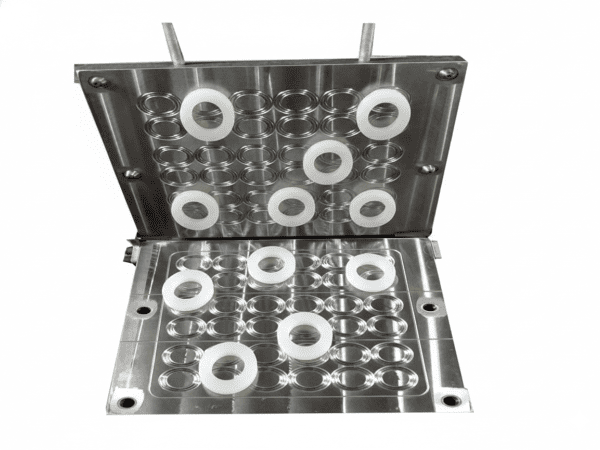

We developed a custom transfer molding process using certified material with multi-cavity tooling for consistent quality and cost-effective production.

Automotive Rubber Seal

Challenge

An automotive OEM required wear resistant o-rings and seals that could withstand extreme temperature variations and maintain flexibility over 10+ years.

Solution

We formulated a custom NBR compound with enhanced wear and oil resistance, using compression molding with precise temperature control for optimal cross-linking.

Resources for Silicon & Rubber Molding

Expert insights and comprehensive guides to help you navigate silicon and rubber molding processes, materials, and best practices.

Silicon Material Selection Guide: Medical vs Industrial Applications

Complete comparison of medical-grade silicone, EPDM, and specialty compounds. Learn which materials work best for your specific application requirements.

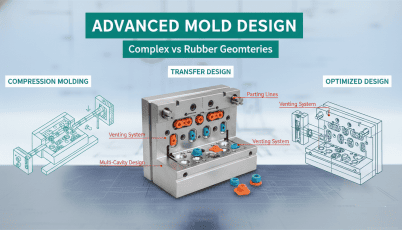

Advanced Mold Design for Complex Rubber Geometries

Master the principles of compression and transfer molding tooling. Optimize parting lines, venting systems, and multi-cavity designs for maximum efficiency.

Quality Testing Methods for Silicon & Rubber Components

Comprehensive testing protocols for durability, chemical resistance, and performance validation. Ensure your rubber parts meet industry standards.

Turn Your Design Into

Manufacturing Reality

Upload your CAD files and receive a detailed quote with DFM analysis within 24 hours. From prototypes to mass production, we're your trusted manufacturing partner.