High-Volume

Metal Stamping

Services

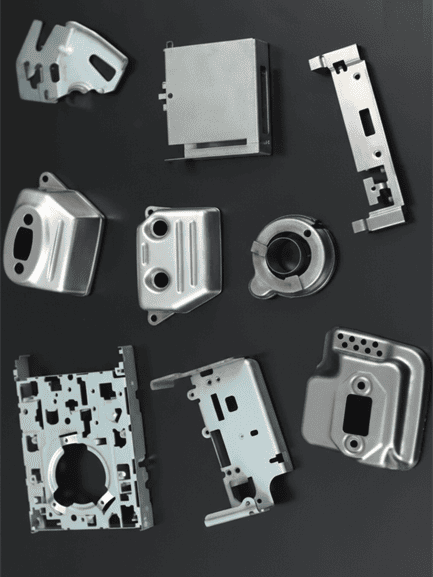

From progressive dies to deep drawing, Xu Feng delivers precision metal stamping for high-volume production with exceptional quality and consistency.

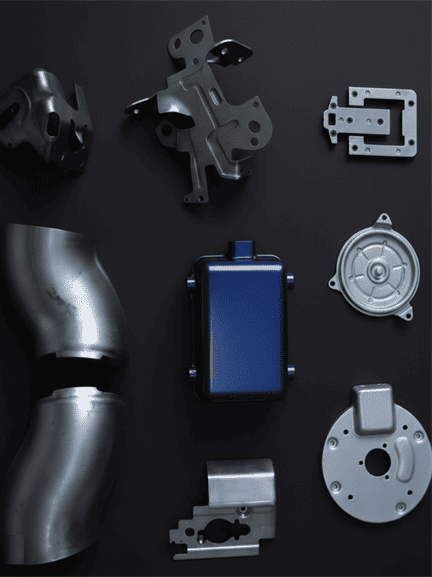

Complete Stamping Solutions

Advanced stamping technologies for automotive, electronics, appliances, and industrial applications with precision dies and high-speed production.

Die & Production Types

Single-Operation Die Stamping

Cost-effective solution for simple parts and medium-volume production. Perfect for prototyping and parts requiring basic cutting, punching, or blanking operations.

- Quick turnaround time for tooling

- Ideal for prototypes and low-medium volumes

- Simple operations: cutting, punching, blanking

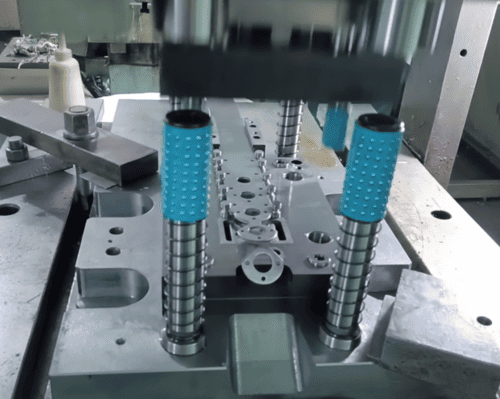

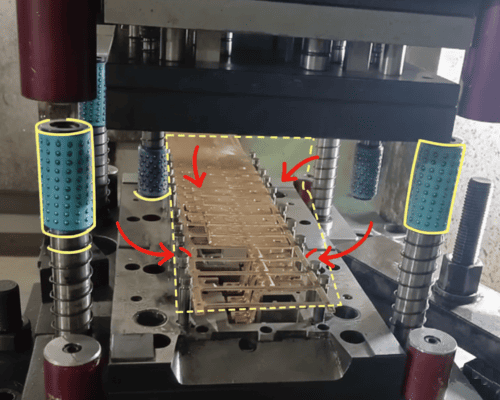

Progressive Die Stamping

High-speed production of complex parts through multiple operations in a single press stroke. Ideal for high-volume automotive and electronics components.

- Complex multi-stage operations in single stroke

- Minimal material waste and high efficiency

- Excellent for high-volume production

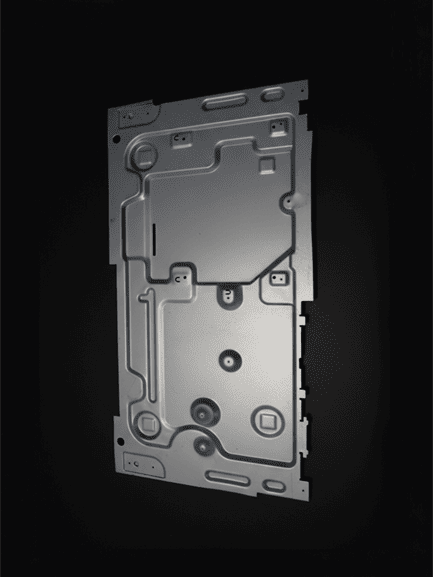

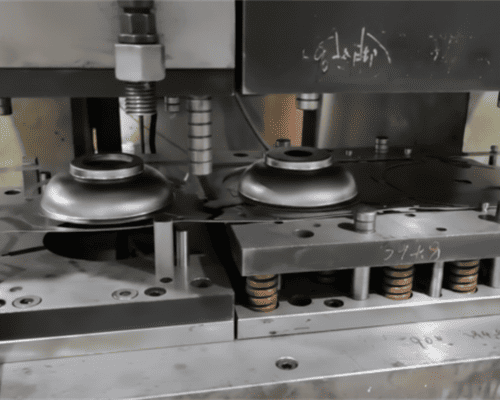

Transfer Die Stamping

Advanced forming process where parts are transferred between stations by mechanical fingers. Perfect for deep drawing and complex 3D shapes requiring multiple forming stages.

- Mechanical transfer between stations

- Complex 3D geometries and deep draws

- High precision and repeatability

Compound Die Stamping

Multiple operations performed simultaneously in a single stroke at the same station. Combines cutting and forming operations for precise, flat parts with tight tolerances.

- Multiple operations in single stroke

- Excellent for flat parts with tight tolerances

- High precision and surface quality

Stamping Processes & Capabilities

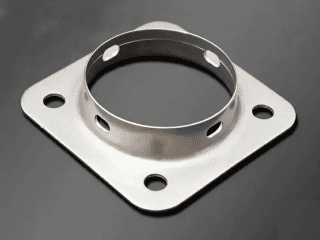

Precision Cutting Operations

High-precision blanking, punching, and shearing operations for creating clean-edge parts from sheet metal. Advanced tooling ensures consistent quality and minimal burr formation.

- Blanking, punching, piercing operations

- Complex contours and hole patterns

- Steel, aluminum, copper alloys

Precision Bending & Forming

Accurate angle bending and forming operations for creating brackets, enclosures, and structural components. Advanced tooling ensures consistent bend angles and minimal springback.

- 90°, acute, and obtuse angle bending

- Multi-bend parts and complex geometries

- Springback compensation and control

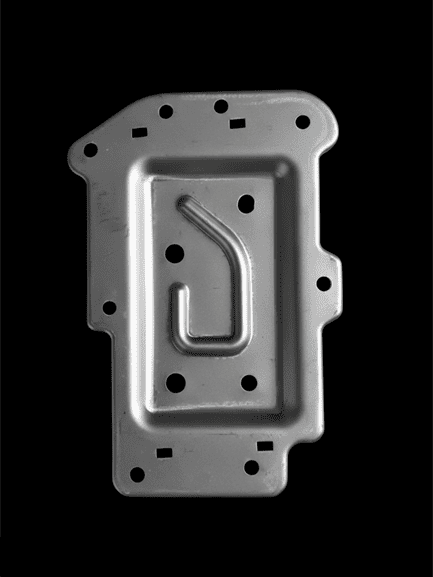

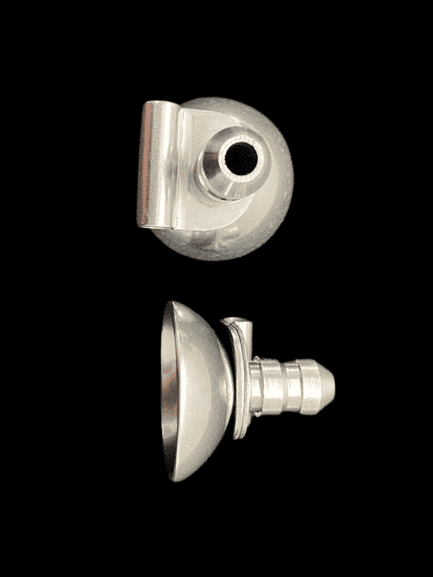

Deep Drawing Operations

Advanced deep drawing processes for creating cups, shells, and complex 3D shapes. Multi-stage operations achieve deep draw ratios while maintaining material integrity.

- Deep cups, shells, and enclosures

- Multi-stage progressive drawing

- Wrinkle and tearing prevention

Advanced Forming Operations

Specialized forming processes including embossing, coining, and bulging for creating textured surfaces, precise features, and complex 3D shapes with exceptional detail.

- Embossing, coining, and bulging

- Textured surfaces and fine features

- High-precision dimensional control

Wide Range of

Materials & Specs

Our stamping capabilities cover a comprehensive range of materials and specifications to meet diverse industrial requirements.

Steel Materials

- Carbon Steel (SPCC, SPCD, SPCE)

- Stainless Steel (304, 316, 430)

- Galvanized Steel (SECC, SGCC)

- High-strength Steel (HSLA)

Non-ferrous Metals

- Aluminum (1100, 3003, 5052, 6061)

- Copper & Brass (C11000, C26000)

- Beryllium Copper (C17200)

- Phosphor Bronze (C51000)

Technical Specifications

Quality Assurance

- Material certification & traceability

- First article inspection (FAI)

- Statistical process control (SPC)

- ISO 9001:2015 certified facility

Your Metal Stamping

Material Guide

Select the perfect metal material for your stamping project. Our expert guide covers stampability, die life considerations, and material-specific parameters to ensure optimal forming results, dimensional accuracy, and cost efficiency.

Surface Finishing Options

Complete your parts with professional surface treatments that enhance durability, appearance, and performance for any application.

Deburring & Surface Prep

- Mechanical deburring

- Tumbling & vibratory finishing

- Surface texturing

Corrosion Protection

- Zinc & nickel plating

- Passivation treatment

- Protective primers

Electrical & Contact

- Gold & silver plating

- Tin plating

- Conductive coatings

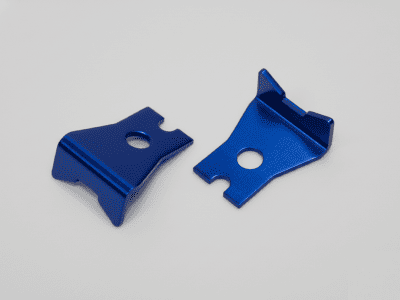

Appearance

- Powder coating

- Anodizing

- Brushed & polished finishes

Surface Finishing Specifications

Comprehensive finishing options for every application requirement

| Finish | Typical Materials | Common Applications | Key Options to Quote | Benefit |

|---|---|---|---|---|

|

Mechanical Deburring

Manual & automated edge finishing

|

Aluminum, Steel, Stainless Steel, Brass | Machined parts, brackets, housings | Edge radius (R0.1-R0.5mm), surface roughness | Safe handling, improved assembly |

|

Tumbling

Mass finishing process

|

Small metal parts, plastic components | Fasteners, small brackets, connectors | Media type, cycle time, surface finish grade | Uniform finish, cost-effective for volume |

|

Surface Texturing

Controlled surface patterns

|

Aluminum, Steel, Plastics | Grips, panels, decorative components | Pattern type, depth, coverage area | Enhanced grip, aesthetic appeal |

|

Zinc Plating

Electroplated protective coating

|

Steel, Iron alloys | Fasteners, brackets, automotive parts | Thickness (5-25μm), chromate type, color | Corrosion resistance, cost-effective |

|

Nickel Plating

Durable metallic coating

|

Steel, Copper, Aluminum | Electronics, hydraulic fittings | Thickness (10-50μm), hardness level | Superior corrosion & wear resistance |

|

Passivation

Chemical surface treatment

|

Stainless Steel, Titanium | Medical devices, food equipment | Process type (citric/nitric), testing req. | Enhanced corrosion resistance |

|

Gold Plating

Precious metal coating

|

Copper, Nickel-plated substrates | Connectors, circuit boards, contacts | Thickness (0.5-5μm), purity grade | Excellent conductivity, corrosion-free |

|

Silver Plating

High conductivity coating

|

Copper, Brass, Steel | RF components, electrical contacts | Thickness (2-15μm), anti-tarnish option | Superior electrical conductivity |

|

Tin Plating

Lead-free solderable finish

|

Copper, Steel, Brass | PCB components, electronic parts | Thickness (5-20μm), reflow compatibility | Excellent solderability, RoHS compliant |

|

Powder Coating

Durable polymer finish

|

Steel, Aluminum, Galvanized metal | Enclosures, frames, architectural parts | Color (RAL/Pantone), texture, thickness | Durable, eco-friendly, color variety |

|

Anodizing

Electrochemical oxide layer

|

Aluminum alloys | Aerospace parts, consumer electronics | Type (II/III), color, thickness (5-25μm) | Hard surface, corrosion resistance |

|

Brushed Finish

Directional surface texture

|

Stainless Steel, Aluminum | Architectural, appliances, trim parts | Grit size, direction, protective coating | Premium appearance, hides fingerprints |

Quick Selection Guide

Tooling & DFM Workflow

From initial RFQ to mass production, our systematic approach ensures optimal tooling design, manufacturing efficiency, and quality assurance at every stage.

RFQ & Drawing Review

- Technical feasibility analysis

- Material recommendations

- Cost estimation & timeline

- 24 hrs quote response

DFM Feedback

- Corner radius optimization

- Bend direction analysis

- Burr direction control

- Grain direction guidance

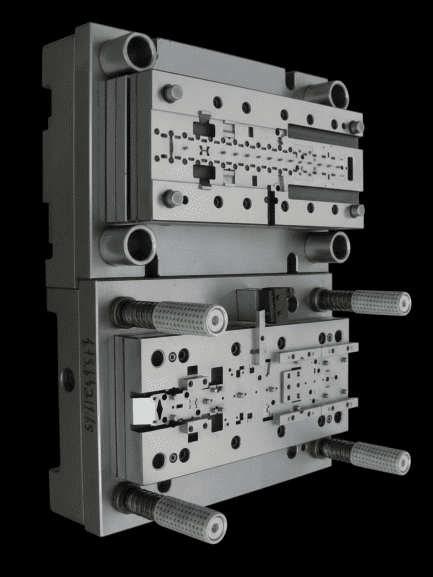

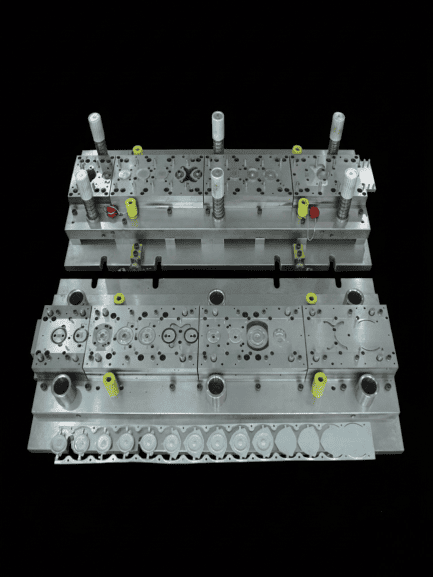

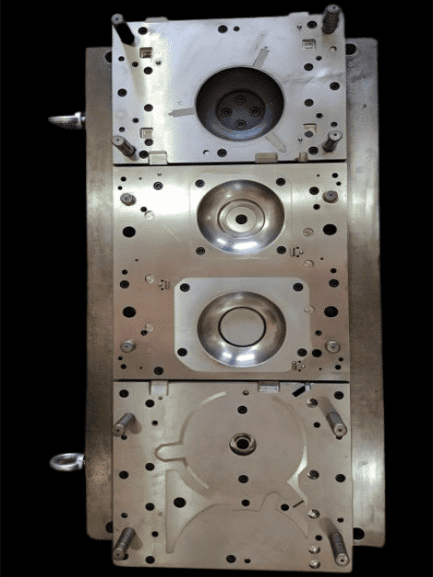

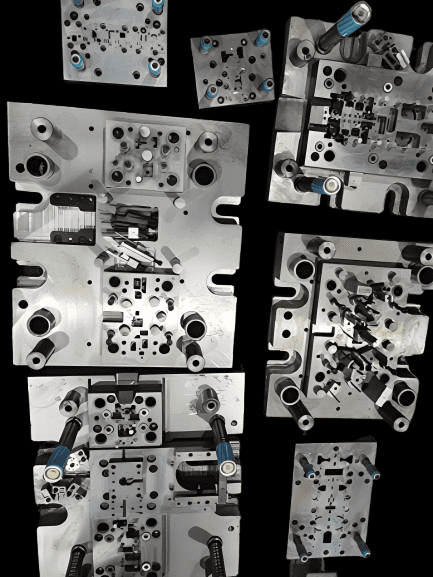

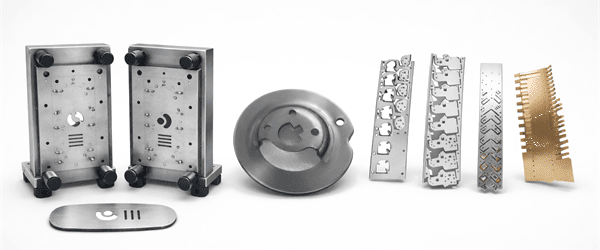

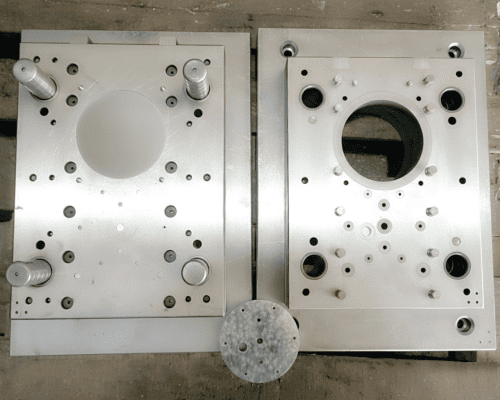

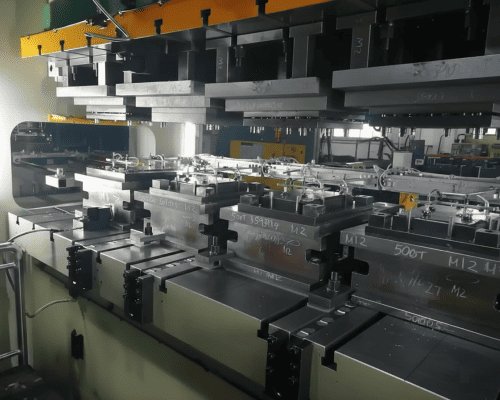

Die Design & Manufacturing

- 3D die design modeling

- Precision CNC machining

- EDM finishing

- Heat treatment & hardening

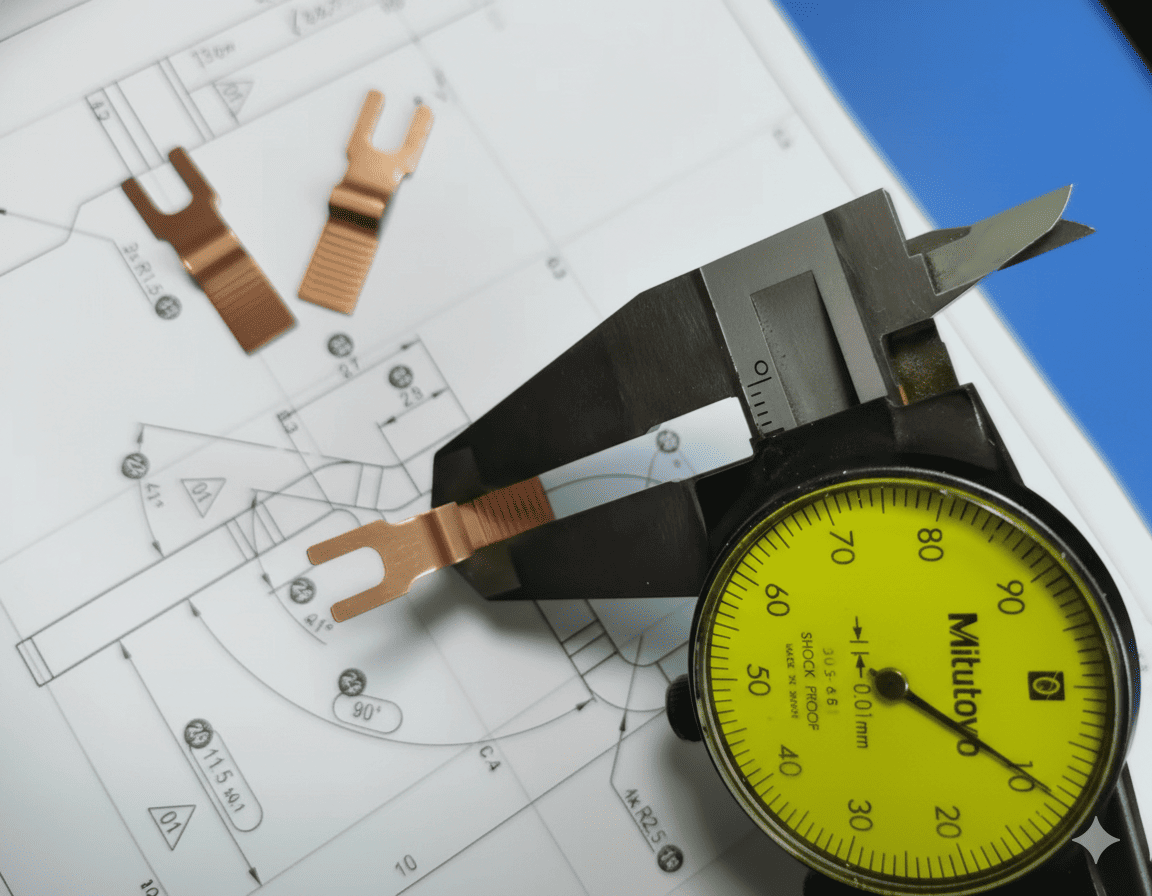

T0/T1 Trial & Inspection

- First article inspection

- Dimensional report (CMM)

- Surface quality check

- Process optimization

Customer Approval & Mass Production

- Sample approval process

- Production planning

- Quality control setup

- High-volume manufacturing

Typical Project Timeline

Comprehensive Resources for Stamping

Leverage our engineering expertise with comprehensive guides covering design optimization, secondary operations, and quality assurance for metal stamping projects.

Design Tips

Optimize your stamping designs for manufacturability with our comprehensive DFM guidelines and best practices.

- Minimum hole-to-edge distance recommendations

- Bend radius to material thickness relationship guidelines

- Burr direction control methods

- Flatness and deformation risk management strategies

- Deep drawing limits and multi-stage drawing strategies

2nd Operations

Complete your stamped parts with our full range of secondary operations and finishing services.

- Deburring/tumbling

- Tapping/threading

- Spot welding/laser welding

- Riveting/press fitting

- Surface treatment

- Assembly

Quality Control

Ensure consistent quality with our ISO-certified processes and comprehensive inspection protocols.

- First article inspection (FAI) procedures

- Statistical process control (SPC)

- CMM and optical inspection

- Material certification and traceability

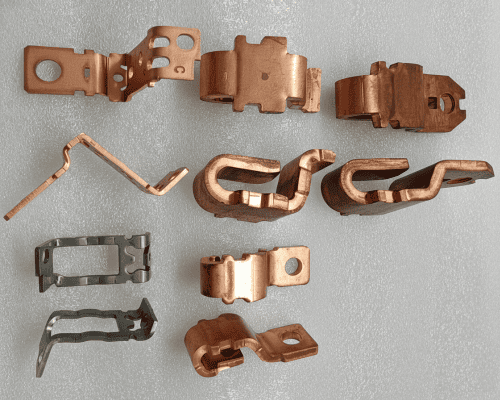

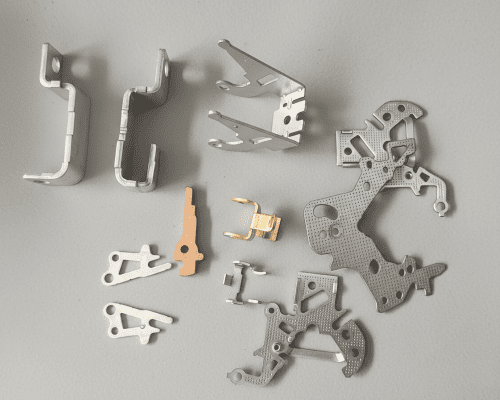

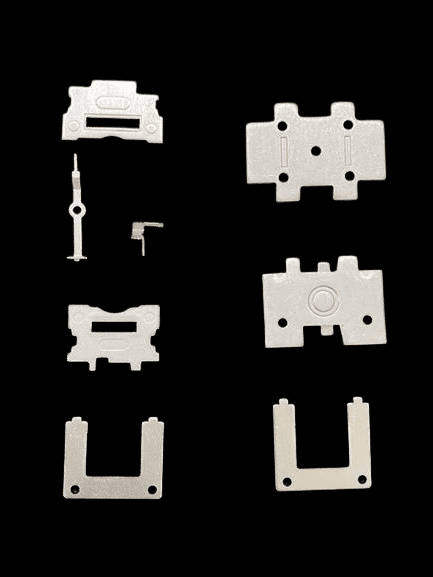

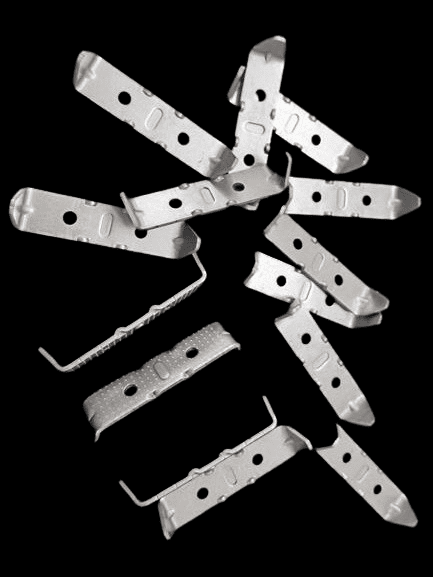

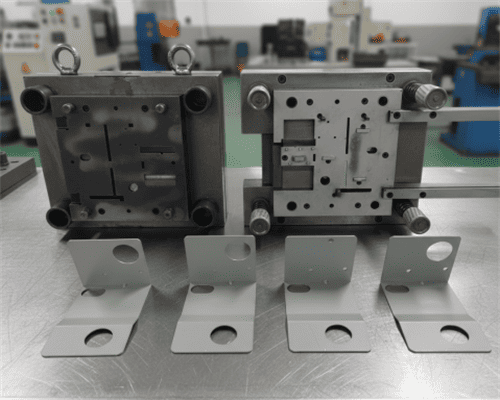

Stamping Parts and Tools

Made By Xu Feng

Frequently Asked

Questions

What are the typical lead times for molds and prototypes?

For mold development, typical lead times are 15-25 days for injection molds and 10-20 days for stamping dies. Prototype parts can be delivered in 5-7 days using CNC machining or 3D printing, allowing for design validation before full tooling investment.

What factors affect MOQ and pricing?

MOQ varies by process: CNC (1-100 pcs), Injection molding (500-1000 pcs), Stamping (5000+ pcs). Pricing factors include material costs, part complexity, tolerance requirements, surface treatments, and order volume. We provide detailed cost breakdowns with every quote.

How do you control burrs and sharp edges?

We implement automated deburring processes including vibratory finishing, tumbling, and precision hand deburring. All sharp edges are chamfered or radiused per drawing specifications. Our quality control includes 100% edge inspection to ensure safe handling and proper fit.

Still Have Questions?

Our engineering team is ready to discuss your specific manufacturing requirements and provide technical guidance.