Progressive

Die Stamping

Solutions

Multiple operations in one press cycle--ideal for terminals, brackets, and complex stamped parts.

Understanding Multi-Stage Metal Forming

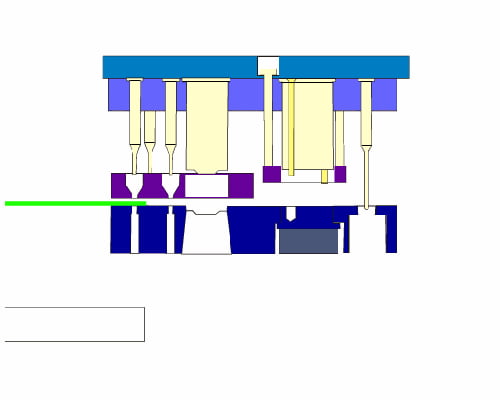

Definition: Progressive die stamping is a continuous feeding process where coil or strip material advances through multiple stations, sequentially performing operations like punching, blanking, bending, forming, and cutting in a single press cycle.

Core Value: Delivers consistent cycle times, exceptional dimensional accuracy, and dramatically reduced unit costs at high volumes. The automated process ensures repeatable quality while minimizing material waste and labor requirements.

Applications: Ideal for manufacturing electrical terminals, connectors, spring contacts, mounting brackets, EMI/RFI shielding cases, and other high-precision metal components requiring millions of identical parts.

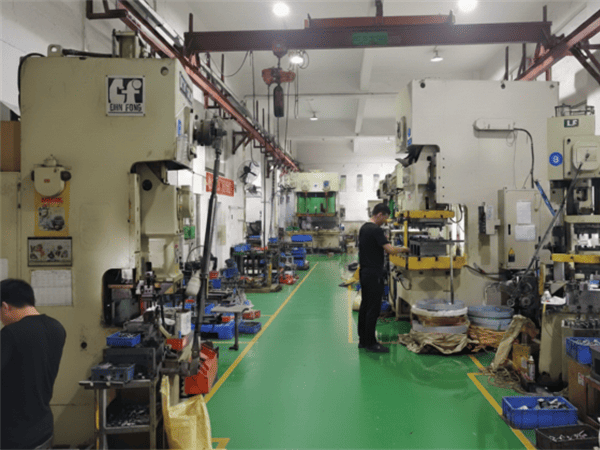

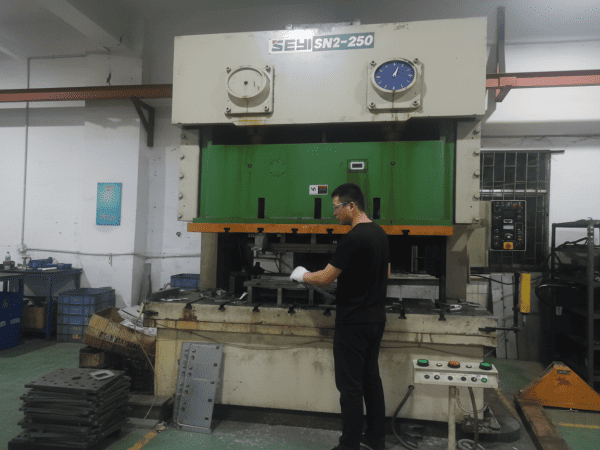

Advanced Stamping Capabilities

State-of-the-art equipment and expert engineering for complex progressive die stamping projects.

Technical Specifications

| Press Tonnage | 25-250T |

| Material Thickness | 0.5-6.0mm |

| Tolerance | ±0.01-±0.05mm |

| Supported Operations |

Piercing

Blanking

Bending

Forming

Coining

Cut-off

|

| Secondary Operations |

|

| Inspection |

FAI

Dimensional Report

CMM

|

From Design to Production

Our comprehensive approach ensures optimal die design and flawless production setup.

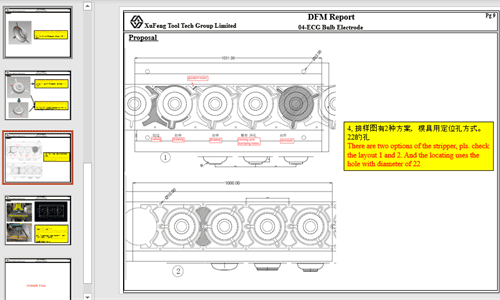

Design Analysis & DFM

- Feasibility study

- Strip layout optimization

- Material utilization analysis

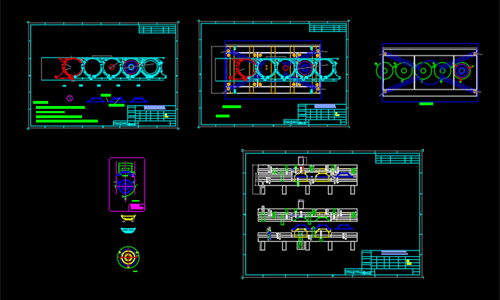

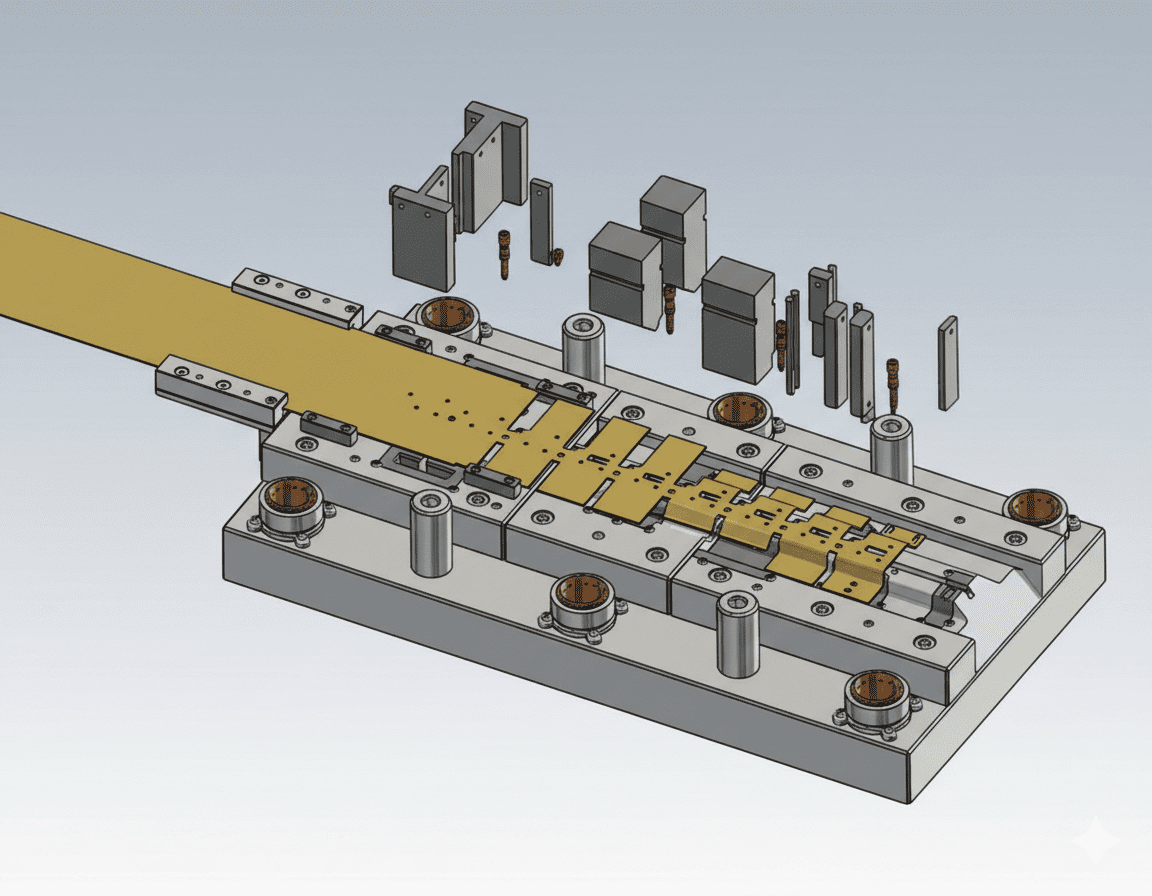

Die Design & Simulation

- 3D die modeling

- Forming simulation

- Spring-back compensation

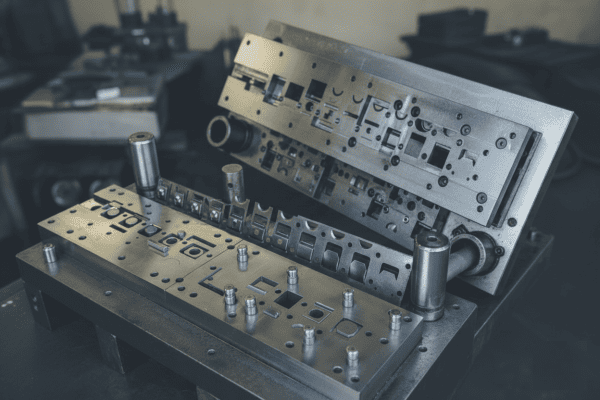

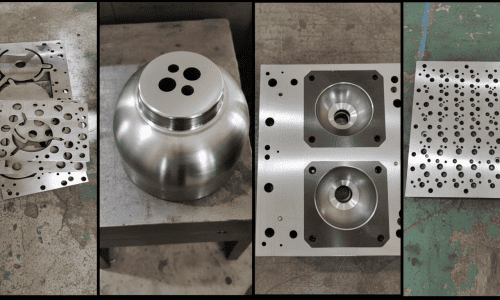

Die Manufacturing & Assembly

- CNC machining

- Heat treatment

- Surface coating

Tryout & Optimization

- First article inspection

- Die adjustments

- Process validation

Understanding Progressive Die Stamping

Make informed decisions with a clear understanding of the benefits and constraints of progressive die stamping.

Key Advantages

High Production Speed

Up to 800 strokes per minute for maximum throughput and reduced per-piece costs.

Excellent Repeatability

Consistent dimensional accuracy across millions of parts with minimal variation.

Complex Geometries

Multiple operations in one pass: punching, bending, coining, and forming.

Material Efficiency

Optimized strip layout minimizes waste and reduces material costs.

Reduced Labor Costs

Automated operation requires minimal operator intervention once setup.

Superior Surface Finish

Cold forming process produces excellent surface quality without secondary operations.

Considerations

High Initial Investment

Die design and manufacturing costs require high-volume production to justify.

Design Constraints

Part geometry must be suitable for progressive forming operations.

Material Limitations

Some materials may not be suitable for cold forming or progressive operations.

Setup Complexity

Initial die setup and optimization can be time-consuming and requires expertise.

Size Limitations

Press bed size and tonnage capacity limit maximum part dimensions.

Design Changes

Modifications to existing dies can be costly and time-consuming.

When is Progressive Die Stamping Right for You?

Progressive die stamping becomes cost-effective when production volumes exceed 50,000-100,000 pieces annually, depending on part complexity.

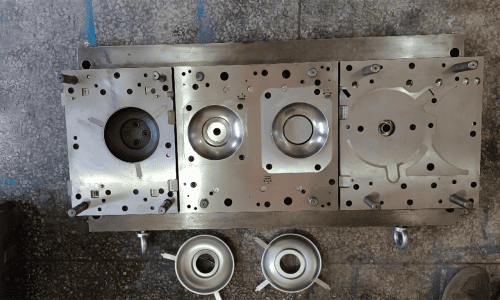

Success Story: Water heater gas cap

How we helped a major automotive supplier reduce costs by 45% while improving quality and delivery times.

Project Overview

Challenge

1-meter press table for 9 steps progressive die. Seeking a supplier capable of transforming a simple hand sketch into a fully functional progressive die.

Solution

We designed a 9-station progressive die and combined selected operations into shared stations to fit the customer’s 1-meter press bed. During the design phase, we also optimized material utilization to minimize scrap, controlled the cut-off/punching loads, and mitigated the risk of drawing splits/tearing. As a result, the process was streamlined without sacrificing dimensional tolerances, while ensuring smooth blanking and reliable part ejection/strip progression.

Read the full caseImpressive Results

Process Comparison

Metal Stamping Knowledge Base

Master the fundamentals of progressive die stamping with our comprehensive technical guides and industry best practices.

How to Choose: Progressive vs Transfer vs Compound Stamping

Compare three major stamping methods to select the optimal approach for your part complexity, volume requirements, and cost targets.

- Production volume analysis

- Part complexity considerations

- Cost-benefit comparison

Progressive Die DFM: Key Design Rules for Cost & Stability

Essential Design for Manufacturing guidelines to optimize your parts for progressive die stamping efficiency and quality.

- Strip layout optimization

- Feature spacing rules

- Material flow considerations

Stamping Quality 101: Tolerance, Burr Control & Inspection

Master quality control fundamentals including tolerance management, burr reduction techniques, and inspection protocols.

- Tolerance stack-up analysis

- Burr formation prevention

- Statistical process control

Need Expert Advice on Your

Stamping Project?

Our engineering team provides free DFM analysis and technical consultation to optimize your parts for progressive die stamping success.