Custom

Sheet Metal

Solutions

From laser cutting to complex assemblies, Xu Feng delivers custom parts and assemblies in as fast as 5 days. Upload your design and get started today.

Complete Manufacturing Solutions

Four core manufacturing categories covering the complete production lifecycle from raw materials to finished products.

Material Removal

- Laser Cutting

- Plasma cutting

- Punching

- Water Jet Cutting

Material Deformation

- Bending

- Metal stamping

- Spinning

- Metal punching

Material Assembly

- TIG/MIG welding

- Hardware insertion

- Sub-assembly services

- Quality testing

Surface Treatment

- Powder coating

- Electroplating

- Anodizing

- Passivation

Removal Technology for Sheet Metal

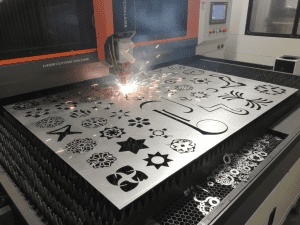

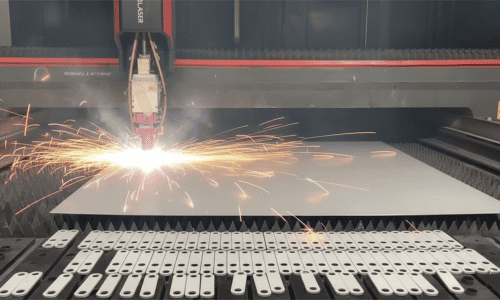

Laser Cutting Technology

High-precision laser cutting delivers exceptional accuracy and clean edges for complex geometries. Our fiber laser systems handle materials from 0.5mm to 25mm thickness with minimal heat-affected zones.

-

Tolerance: ±0.2mm for most materials

-

Materials: Steel, stainless steel, aluminum, brass

-

Max Size: 1500mm × 1000mm

-

Applications: Precision parts, prototypes, decorative panels

Plasma Cutting Technology

High-speed plasma cutting for thick materials and large-scale production. Ideal for structural components and heavy-duty applications requiring fast processing of thick steel plates.

-

Tolerance: ±0.5mm for standard applications

-

Materials: Carbon steel, stainless steel up to 25mm

-

Max Size: 1250mm × 1100mm

-

Applications: Structural parts, thick plates, industrial components

Water Jet Cutting Technology

Ultra-precise abrasive water jet cutting with no heat-affected zone. Perfect for sensitive materials and applications requiring the highest precision and surface quality.

-

Tolerance: ±0.05mm ultra-precision

-

Materials: Any material up to 100mm thick

-

Max Size: 630mm × 630mm

-

Applications: Aerospace parts, medical devices, exotic alloys

Punching Technology

High-speed punching for efficient production of holes, slots, and simple shapes. Cost-effective solution for high-volume production with standard tooling.

-

Tolerance: ±0.2mm for standard punching

-

Materials: Steel, aluminum up to 6mm thick

-

Max Size: 1500mm × 500mm

-

Applications: Electrical panels, brackets, perforated sheets

Deformation Technology for Sheet Metal

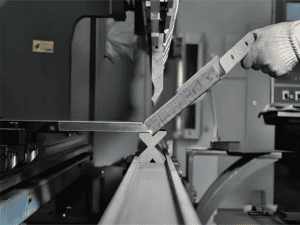

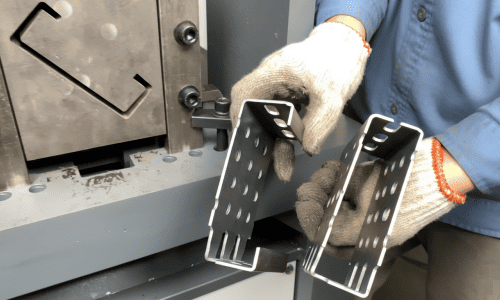

Precision Sheet Metal Bending

Advanced CNC press brake technology delivers precise angular bends with consistent repeatability. Our multi-axis press brakes handle complex geometries and tight tolerances for demanding applications.

-

Tolerance: ±0.1° angular accuracy, ±0.1mm dimensional

-

Materials: Steel, stainless steel, aluminum up to 6 mm

-

Max Length: 500mm bending length

-

Applications: Enclosures, brackets, architectural panels

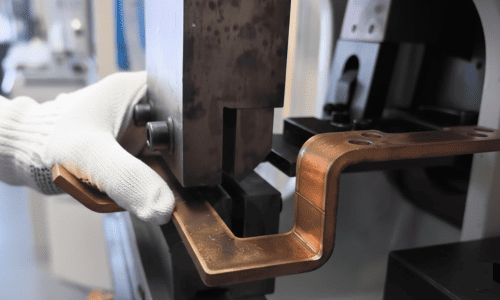

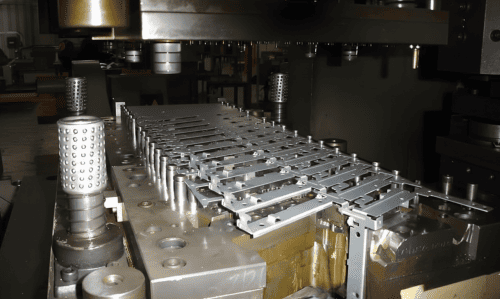

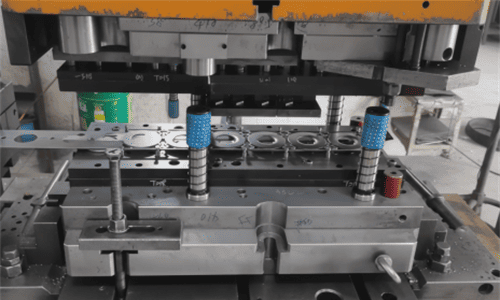

Progressive Die Stamping

High-volume progressive and transfer die stamping for complex formed parts. Custom tooling design and manufacturing for automotive, electronics, and industrial applications with superior surface finish.

-

Tolerance: ±0.05mm for critical dimensions

-

Materials: Steel, stainless, aluminum, copper alloys

-

Volume: 10,000 to 10M+ parts annually

-

Applications: Automotive parts, electronic housings, connectors

Stretch Forming Process

Advanced stretch forming technology for creating complex curved and contoured sheet metal parts. Ideal for aerospace, automotive, and architectural applications requiring precise forming of large panels and structural components.

-

Tolerance: ±0.3mm dimensional accuracy

-

Materials: Aluminum alloys, titanium, stainless steel

-

Max Size: Up to 800mm x 500mm panels

-

Applications: Aircraft panels, automotive body parts, architectural facades

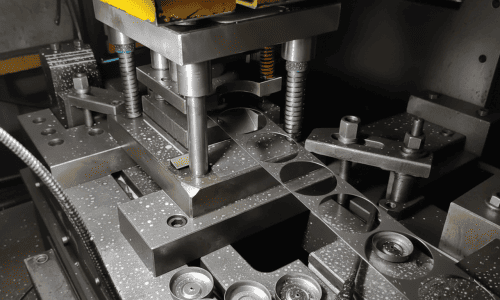

Forming & Deformation Punching

Advanced forming operations including embossing, coining, and three-dimensional deformation. Creates complex features like louvers, ribs, and formed threads without material removal.

-

Tolerance: ±0.1mm for formed features

-

Materials: Steel, aluminum up to 5mm thickness

-

Force: Up to 400 tons forming pressure

-

Applications: Ventilation grilles, structural reinforcement, decorative features

Assembly Technology for Sheet Metal

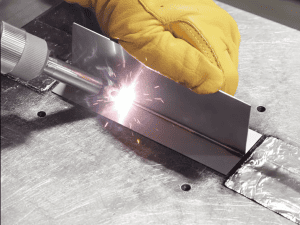

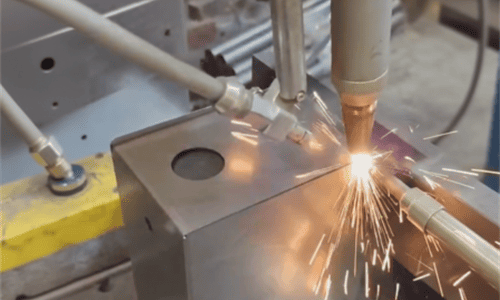

TIG/MIG Welding Services

Professional TIG and MIG welding for precision joining of sheet metal components. Our certified welders deliver high-quality joints for structural, aesthetic, and functional applications with full penetration control.

-

Weld Quality: AWS D1.1 certified welding standards

-

Materials: Steel, stainless steel, aluminum alloys

-

Thickness Range: 0.5mm to 20mm material thickness

-

Applications: Frames, enclosures, structural assemblies

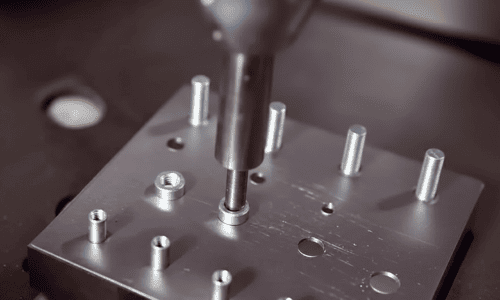

Hardware Insertion Services

Professional insertion of threaded fasteners, rivets, and specialized hardware components. Automated and manual insertion processes ensure consistent quality and proper installation torque specifications.

-

Hardware Types: PEM fasteners, rivnuts, standoffs, inserts

-

Installation: Automated press insertion with torque control

-

Material Range: 0.8mm to 6mm sheet thickness

-

Applications: Electronic enclosures, chassis, mounting panels

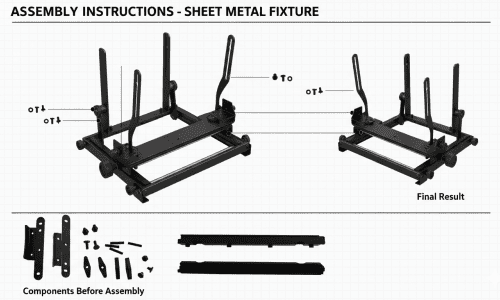

Sub-assembly Services

Complete sub-assembly services combining multiple sheet metal components with mechanical fasteners, gaskets, and accessories. Streamline your supply chain with ready-to-install assemblies.

-

Assembly Types: Multi-component chassis, enclosures, frames

-

Components: Gaskets, hinges, latches, electronic components

-

Quality Control: 100% functional testing and inspection

-

Applications: Industrial equipment, control panels, server racks

Wide Range of Metal Materials

From standard grades to specialized alloys, we work with various metal materials to meet your specific requirements.

Carbon Steel

Q235, A36, 1018, 1045

- • Cost-effective

- • High strength

- • Easy welding

Stainless Steel

304, 316, 316L, 430

- • Corrosion resistant

- • Food grade options

- • Excellent finish

Aluminum

6061, 6063, 5052, 7075

- • Lightweight

- • Anodizing ready

- • Good conductivity

Specialty Alloys

Brass, Copper, Titanium

- • Custom properties

- • High performance

- • Specialized applications

Your Sheet Metal

Material Guide

Choose the optimal metal material for your sheet metal fabrication project. Our comprehensive guide covers material properties, forming characteristics, and application-specific recommendations to maximize strength, durability, and cost-effectiveness.

Premium Surface Finishes

Explore our comprehensive range of surface treatment options for enhanced durability and aesthetics.

Sheet Metal Finishing Options

Professional surface treatments and finishing options to enhance durability, appearance, and performance of your sheet metal components.

Powder Coating

Durable, eco-friendly finish with excellent corrosion resistance and color options.

Part Marking

Precise laser engraving, silk screening, and permanent marking solutions for part identification and branding.

E-Coating

Electrochemical process creating a durable layer for enhanced corrosion resistance and aesthetic finish.

Brushed Finish

Professional brushed texture for premium appearance and feel.

Sheet Metal Design Guide

Essential design parameters and best practices for optimal sheet metal fabrication results.

| Parameter | Recommended Values | Material Impact | Design Notes |

|---|---|---|---|

|

|

0.5t - 2t

(t = material thickness)

|

Steel: 0.5t

Aluminum: 1t

Stainless: 1.5t

|

Smaller radius = higher stress concentration. Consider material grain direction. |

|

|

≥ 1.5t

Minimum recommended

|

Thin sheets: ≥ 2t

Thick sheets: ≥ 1t

|

Too small holes may cause material distortion during punching. |

|

|

≥ 2t

From edge to hole center

|

Steel: 2t

Aluminum: 2.5t

Stainless: 3t

|

Insufficient distance may cause edge tearing or deformation. |

|

|

≥ 1t width

Length: bend radius + 1t

|

All materials

Critical for thick sheets

|

Prevents material tearing at bend intersections. Use rectangular or round relief. |

|

|

≥ 4t

Minimum for stability

|

Standard: 4t - 6t

Heavy duty: 8t+

|

Short flanges may not form properly and reduce structural integrity. |

|

|

Gap: 0.5t - 1t

For butt joints

|

Thin: 0.5t gap

Thick: 1t gap

Bevel for >6mm

|

Proper gap ensures full penetration. Consider thermal expansion. |

Material Selection

Choose materials based on strength, corrosion resistance, and formability requirements. Consider grain direction for complex bends.

Tolerance Planning

Standard tolerances: ±0.1mm for cut edges, ±0.5mm for bent dimensions. Tighter tolerances require secondary operations.

Cost Optimization

Minimize waste by nesting parts efficiently. Standardize hole sizes and bend radii. Avoid unnecessary tight tolerances.

Complete Design Reference Manual

Access our detailed sheet metal fabrication guide with advanced design principles, material specifications, tolerance charts, and real-world examples to optimize your manufacturing process.

- Advanced bend calculations and spring-back compensation

- Material property tables for 10+ alloys

- Cost optimization strategies and DFM checklists

- CAD templates and design examples

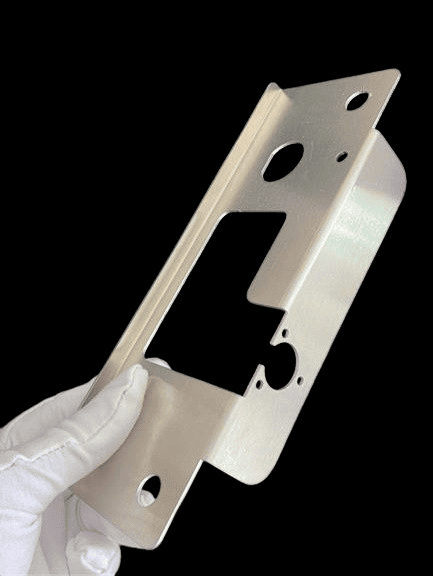

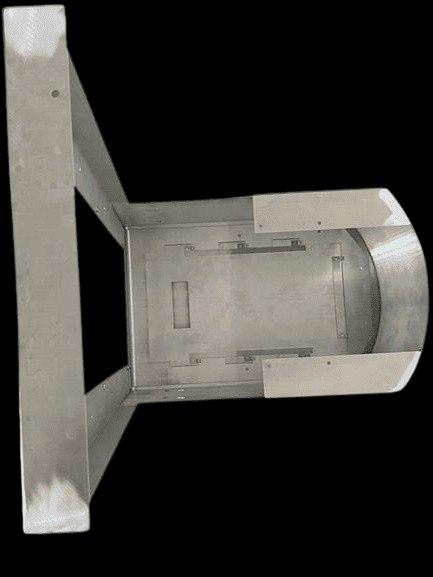

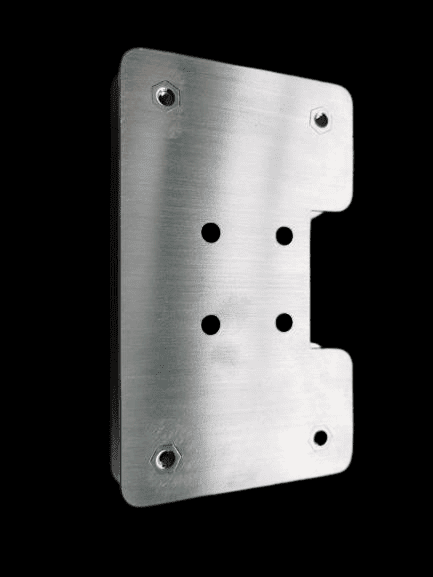

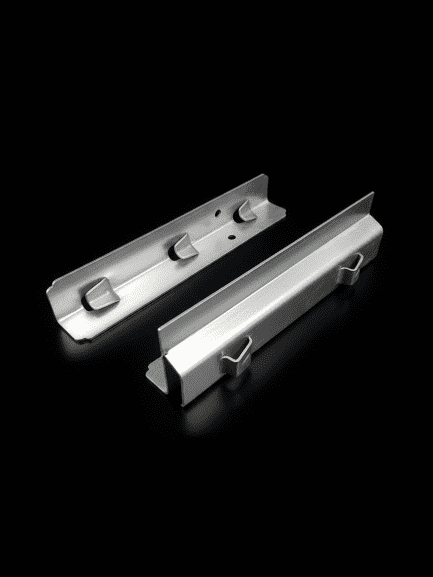

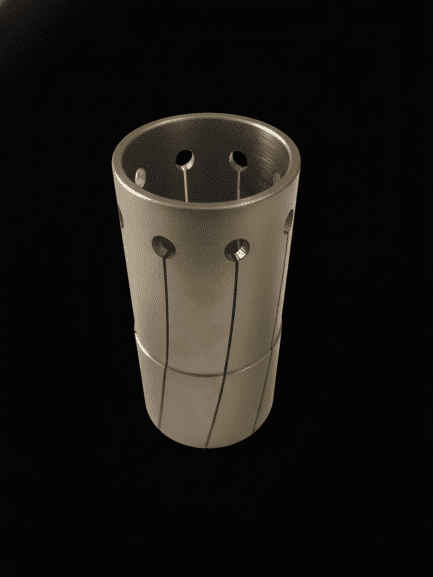

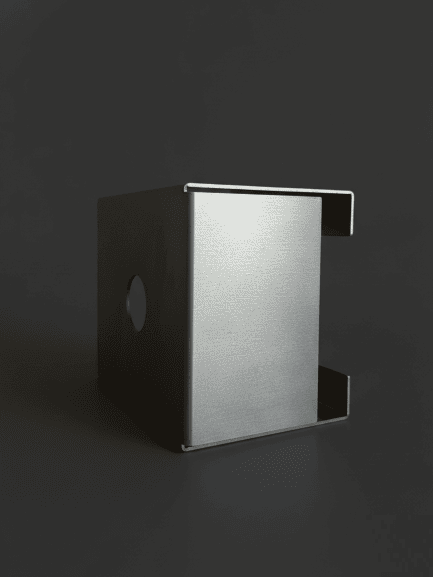

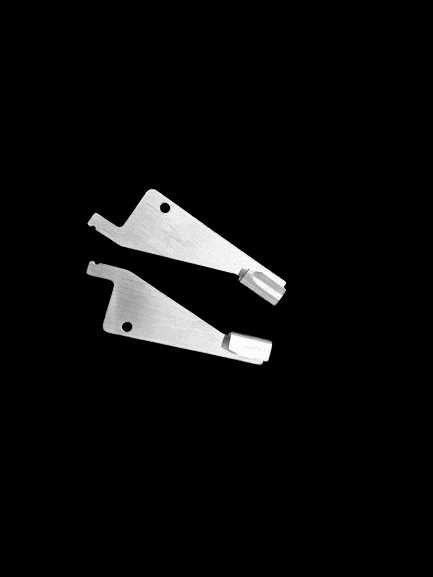

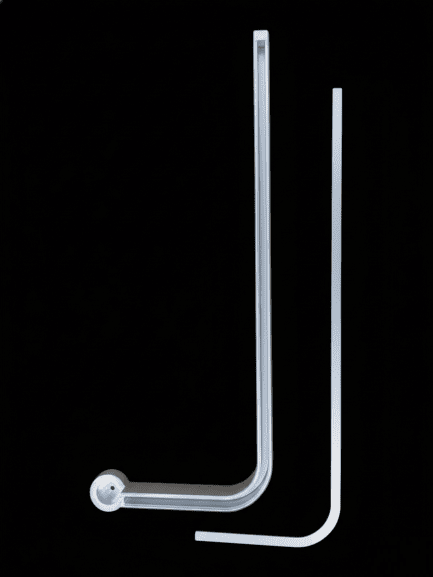

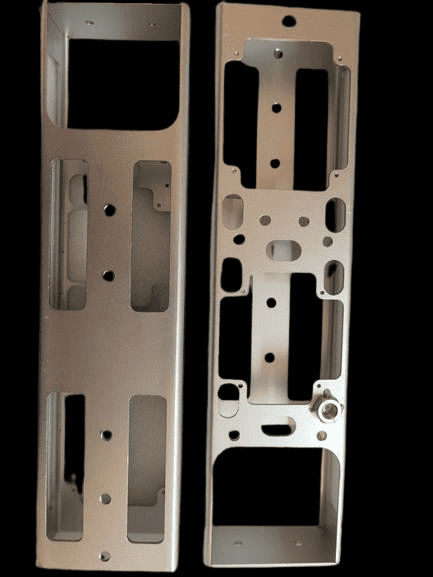

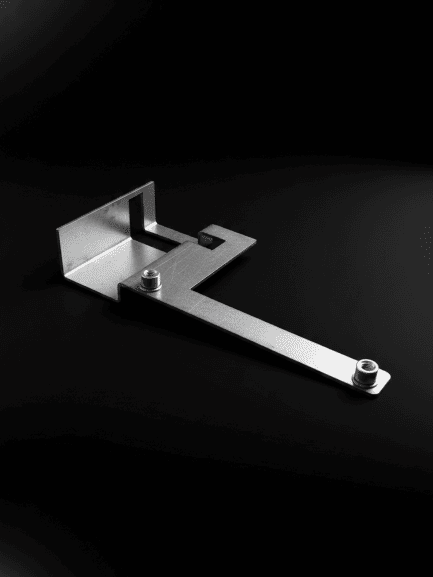

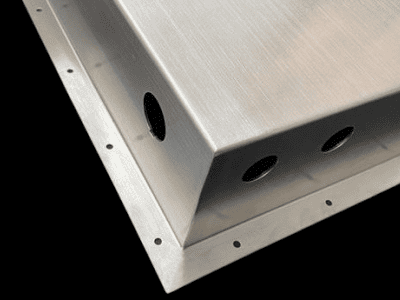

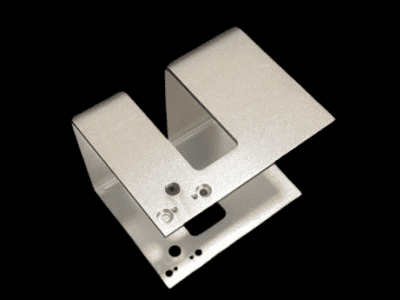

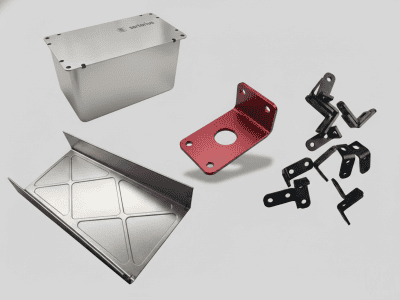

Sheet Metal Parts Made By Xu Feng

Precision-crafted sheet metal components and tools showcasing our manufacturing excellence and attention to detail.

Frequently Asked

Questions

Get answers to the most common questions about our sheet metal fabrication services

What materials do you work with for sheet metal fabrication?

We work with a wide range of materials including mild steel, stainless steel (304, 316), aluminum alloys (5052, 6061), copper, brass, and galvanized steel. Our laser cutting capabilities handle thicknesses from 0.5mm to 25mm depending on the material. We also offer various surface treatments including powder coating, anodizing, zinc plating, and chrome plating.

What is your typical lead time for sheet metal parts?

Our standard lead time is 5-10 working days for most sheet metal projects, depending on complexity and quantity. Simple laser cutting jobs can be completed in 3-5 days, while complex assemblies with welding and finishing may take 7-15 days. We offer expedited service for urgent projects with 24-48 hour turnaround for simple parts. Lead times may vary during peak seasons.

What tolerances can you achieve with sheet metal fabrication?

Our laser cutting achieves ±0.1mm tolerance for most materials. Bending operations typically maintain ±0.2mm on dimensions and ±1° on angles. For critical dimensions requiring tighter tolerances, we can achieve ±0.05mm through secondary machining operations. All parts undergo quality inspection with CMM measurement and detailed inspection reports are provided upon request.

Still Have Questions?

Our engineering team is here to help with technical questions, design optimization, and custom manufacturing solutions.