Professional

Metal Bending

Services

Advanced sheet metal bending capabilities for complex geometries with ±0.2mm precision. From prototypes to production runs, we deliver bent metal components across 25+ countries.

What is Metal Bending

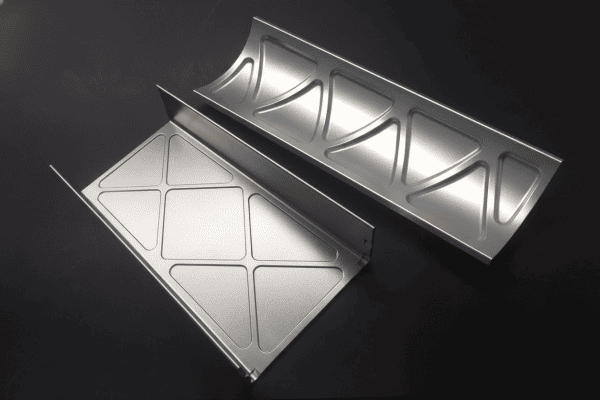

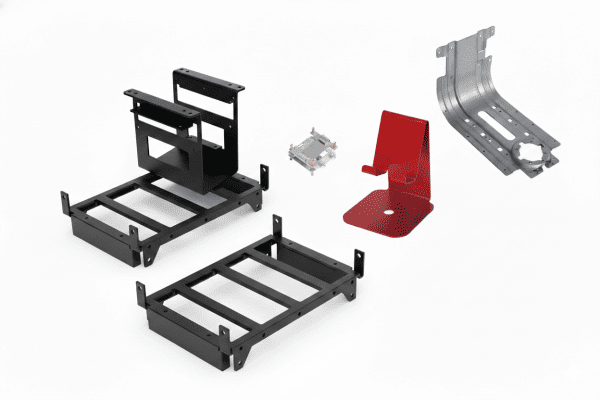

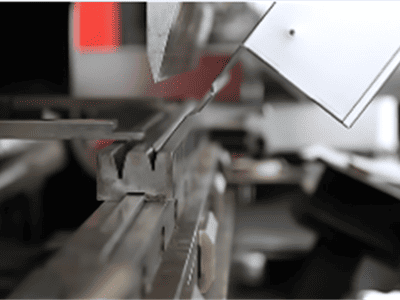

Metal bending is a precision sheet metal fabrication process that creates angular shapes and complex geometries using advanced press brake technology.

At Xu Feng, we deliver high-quality bent metal parts for medical devices, electronics, automotive, and industrial equipment with strict dimensional tolerances.

Metal Bending Capabilities

Advanced equipment and expertise for complex bending operations across diverse materials and applications.

Bending Methods & Equipment

Press Brake Bending

CNC press brakes up to 400 tons capacity for precise angle control and repeatability

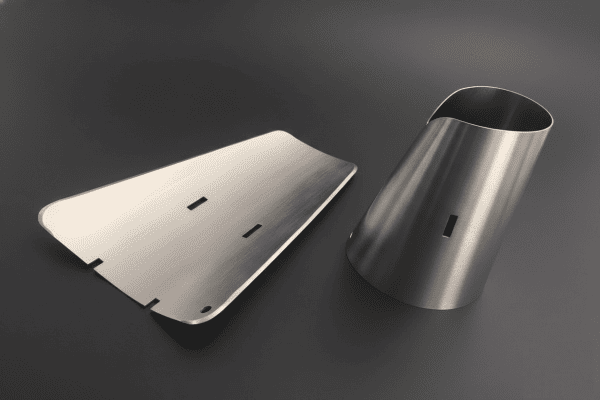

Roll Bending

Three-roll and four-roll bending machines for curved profiles and cylindrical shapes

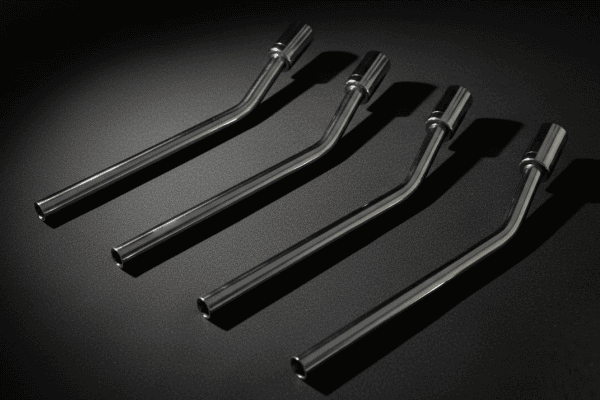

Rotary Draw Bending

Tube and pipe bending with mandrel support for complex geometries without deformation

Material Specifications

| Material | Thickness Range | Min. Bend Radius | Applications |

|---|---|---|---|

|

Mild Steel

|

0.5mm - 6mm | 0.5 × thickness | Brackets, enclosures, structural parts |

|

Stainless Steel 304/316

|

0.5mm - 4mm | 1.0 × thickness | Medical devices, food equipment |

|

Aluminum 5052/6061

|

0.8mm - 5mm | 1.5 × thickness | Electronics, aerospace components |

|

Copper/Brass

|

0.5mm - 4mm | 0.5 × thickness | Electrical components, decorative parts |

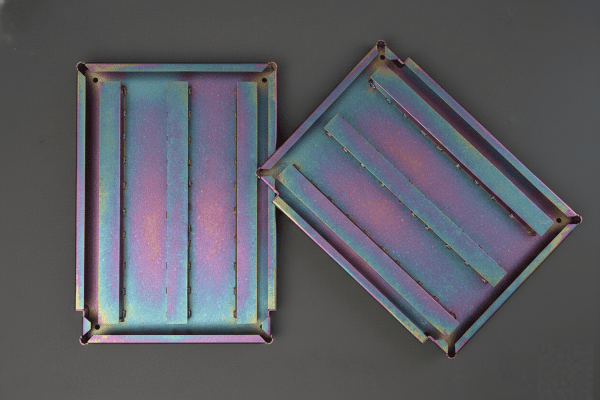

Metal Bending Surface Finishes

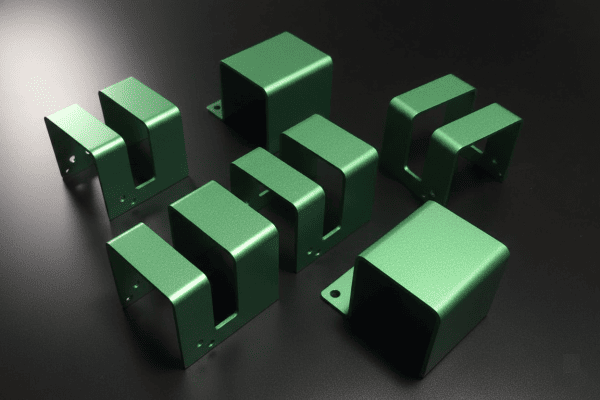

Powder Coating

Durable coating with excellent corrosion resistance

Anodizing

Enhanced surface hardness for aluminum parts

Galvanizing

Maximum corrosion protection for harsh environments

Electroplating

Precision plating for decorative applications

Mark Making

Laser marking and engraving for part identification

Brushing

Brushed finish for aesthetic and functional surfaces

Metal Bending Advantages

Precision engineering with rapid turnaround times.

Cost Efficiency

Reduce material waste and tooling costs with optimized bending processes.

Enhanced Strength

Work hardening during bending increases material strength along bend lines.

Versatile Design

Create intricate geometries and multi-angle bends for innovative designs.

Rapid Production

Fast setup times deliver your components in 5-7 days from prototype to production.

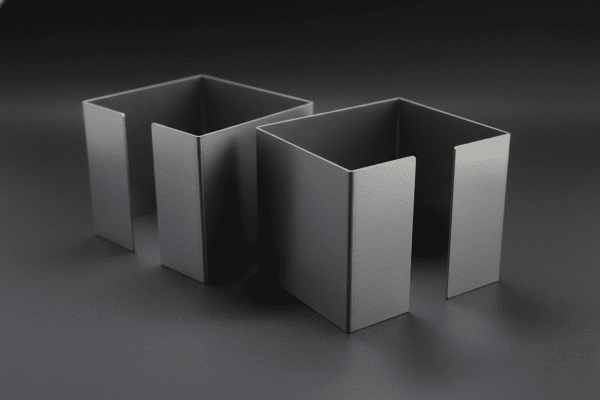

Precision Bending for Critical Components

Our advanced press brake technology delivers precise metal bending solutions for essential components across industries, ensuring perfect angles and consistent quality.

Why Choose Our Bending Services

Resources for Metal Bending

Learn from our engineering expertise with comprehensive guides covering metal bending techniques, best practices, and design optimization.

Complete Guide to Sheet Metal Bending Techniques

Master the fundamentals of sheet metal bending, from air bending to coining, with detailed explanations of each technique's advantages and applications.

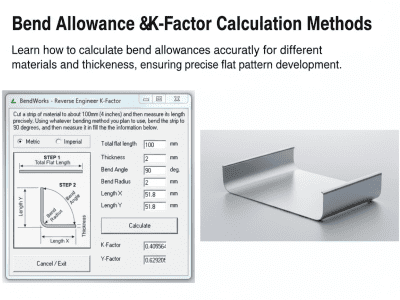

Bend Allowance & K-Factor Calculation Methods

Learn how to calculate bend allowances accurately for different materials and thicknesses, ensuring precise flat pattern development.

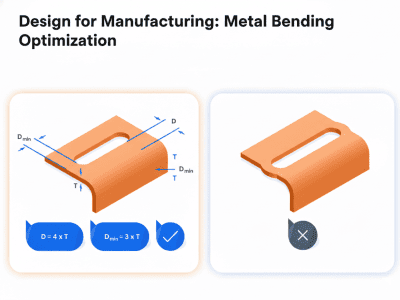

Design for Manufacturing: Metal Bending Optimization

Optimize your designs for metal bending with expert DFM guidelines covering minimum bend radii, hole placement, and material selection.

Ready to Apply Your Knowledge?

Put these metal bending principles into practice with Xu Feng's precision sheet metal fabrication services.