Engineering &

DFM Support

for Custom Parts

Get professional DFM analysis and engineering recommendations to optimize your designs for lower costs, faster delivery, and superior quality.

What You Get

Comprehensive DFM analysis delivered within 24-72 hours with actionable recommendations.

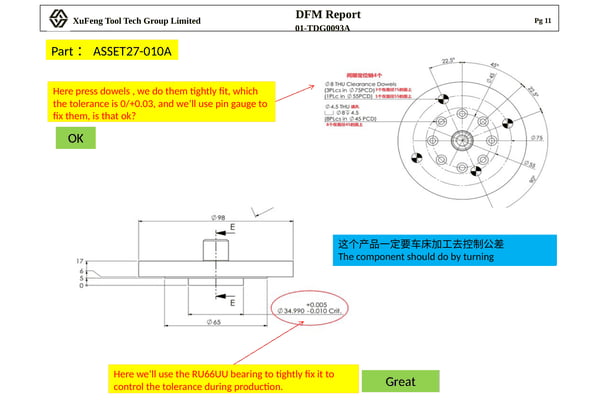

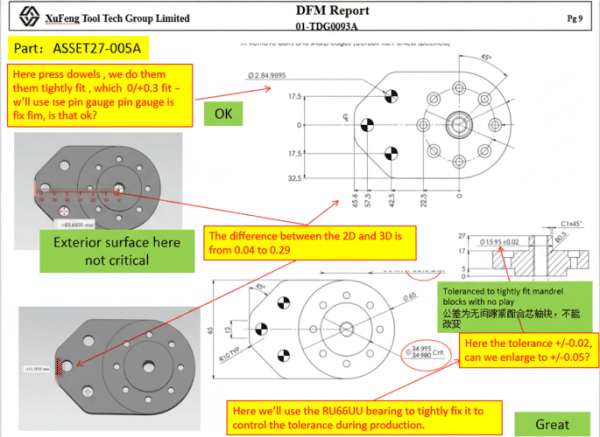

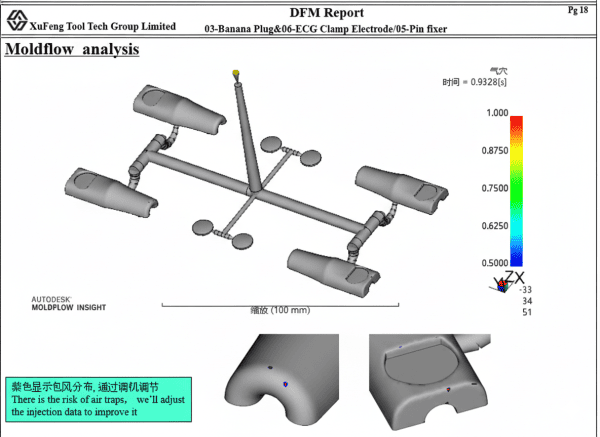

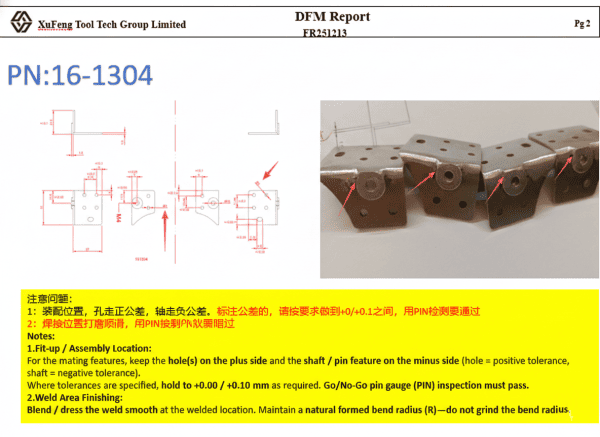

DFM Analysis Report

24-72hDFM by Process

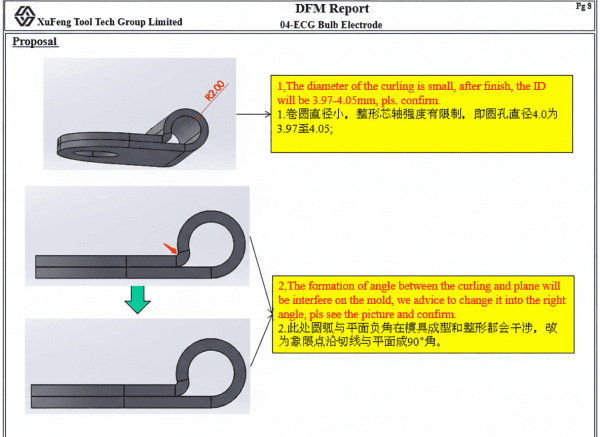

Process-specific design optimization guidelines for maximum manufacturability.

CNC Machining

Precision milling & turning optimization

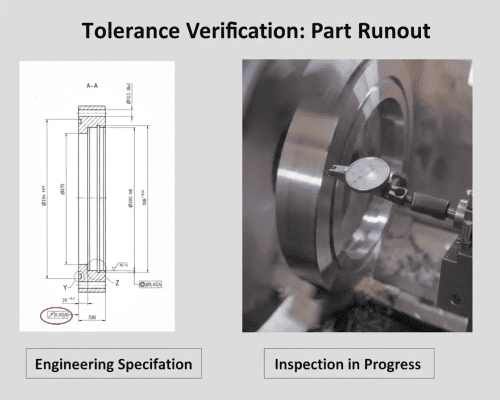

Tolerance &

GD&T Support

Define critical characteristics and establish appropriate inspection methods for consistent quality control.

Critical Characteristic Definition

Identify functional dimensions that directly impact part performance and assembly requirements.

Inspection Method Selection

Recommend appropriate measurement tools: CMM for complex geometries, custom fixtures for production inspection.

Material & Finish Selection

Avoid common material selection mistakes with expert recommendations based on application requirements.

Common Mistakes

Best Practices

Cost Reduction Examples

Real-world examples of how DFM optimization reduced manufacturing costs by 20%.

Original Design

- • 5 setups required

- • Sharp internal corners

- • Tight tolerances throughout

Optimized Design

- • 2 setups only

- • Tool-friendly radii

- • Relaxed non-critical tolerances

Reduce Setups

Minimize workholding changes and part repositioning

Simplify Operations

Combine multiple operations into single processes

Material Optimization

Select cost-effective materials without compromising function

Tolerance Relaxation

Apply tight tolerances only where functionally required

Finish Selection

Choose appropriate surface treatments based on application

DFM Design Checklist

A comprehensive checklist to optimize your designs before manufacturing. Download or copy for your team.

General Design

- Material selection based on function, not preference

- Tolerances applied only where functionally required

- Standard fasteners and hardware specified

- Surface finish requirements clearly defined

Process Specific

- CNC: Internal corners have appropriate radii

- Injection: Draft angles on all vertical surfaces

- Sheet Metal: Bend radius ≥ material thickness

- Stamping: Corner radii prevent stress concentration

Assembly Considerations

- Access for assembly tools considered

- Part orientation and handling features included

- Alignment features for mating parts

Quality Control

- Critical dimensions clearly identified

- Inspection access points available

- GD&T symbols used correctly

Frequently Asked Questions

Common questions about our DFM analysis service.

What file formats do you need for DFM analysis?

We accept STEP (.stp), IGES (.igs), and native CAD files (SolidWorks, AutoCAD, Inventor, etc.). 2D drawings in PDF format are also helpful for understanding critical dimensions and tolerances. For the most comprehensive analysis, please provide both 3D models and 2D drawings.

How quickly can you provide DFM feedback?

Standard DFM analysis is delivered within 24-72 hours. For simple parts, we can often provide initial feedback within 24 hours. Complex assemblies or multi-process parts may require up to 72 hours for comprehensive analysis. Rush analysis is available upon request.

Do you modify CAD files or just provide recommendations?

We provide detailed engineering recommendations and can create modified CAD files upon request. Our standard DFM report includes marked-up drawings showing suggested changes. If you need revised CAD models, we can provide those as an additional service after you approve the recommended modifications.

Is DFM analysis included in your quoting process?

Yes, basic DFM feedback is included with all manufacturing quotes at no additional cost. This includes manufacturability assessment, material recommendations, and cost optimization suggestions. Detailed DFM reports with comprehensive analysis and alternative design options are available as a separate service.

Can you handle multi-process parts requiring different manufacturing methods?

Absolutely. With our three specialized factories covering CNC machining, injection molding, sheet metal fabrication, and stamping, we can analyze and optimize parts requiring multiple processes. We'll recommend the most efficient manufacturing sequence and identify opportunities to combine operations for cost savings.

Request Professional

DFM Review

Upload your CAD files and receive detailed DFM analysis with cost reduction recommendations within 24-72 hours.