What We Can Make

Deep Drawn & Formed Solutions You Can Source Here

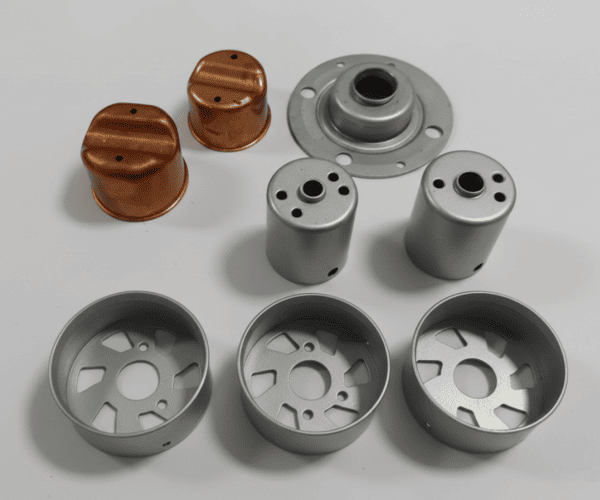

Deep Drawing Excellence

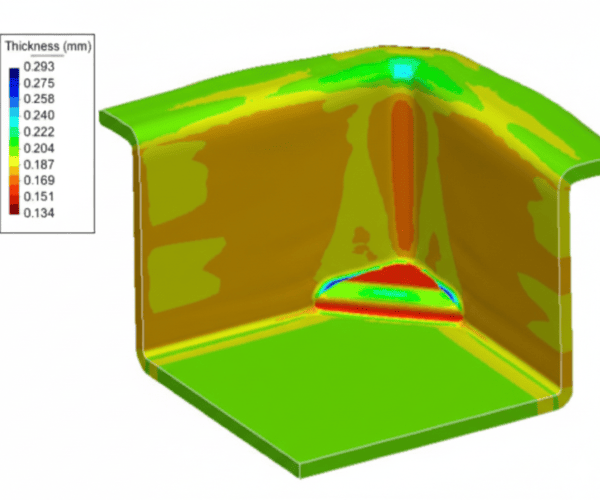

Our deep drawing capabilities transform flat metal sheets into complex three-dimensional shapes through controlled plastic deformation. Perfect for high-volume production of cylindrical and box-shaped components.

-

Cylindrical ComponentsCups, cans, tubes, and motor housings with precise wall thickness control

-

Rectangular ShapesBattery cases, enclosures, and automotive components

-

Material RangeAluminum, steel, stainless steel, copper, and specialized alloys

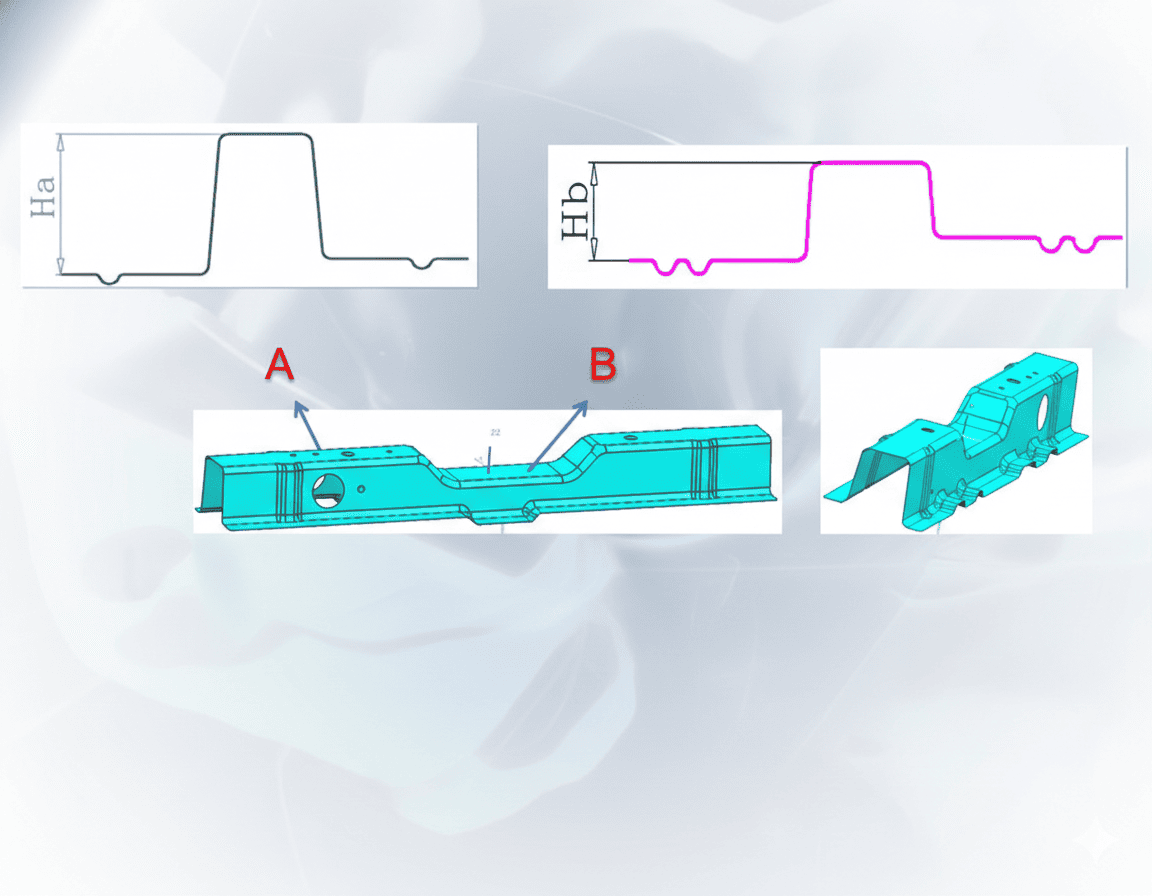

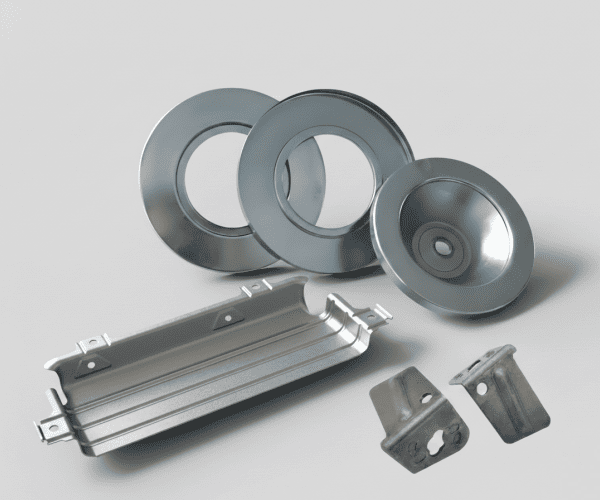

Stretch Forming Precision

Stretch forming creates large, smooth curved surfaces by stretching metal sheets over specially designed forms. Ideal for aerospace, automotive, and architectural applications requiring complex contours.

-

Aerospace ComponentsWing skins, fuselage panels, and structural elements with complex curves

-

Automotive PanelsBody panels, trim pieces, and decorative elements

-

Large Format CapabilityParts up to 6m length with consistent thickness and surface quality

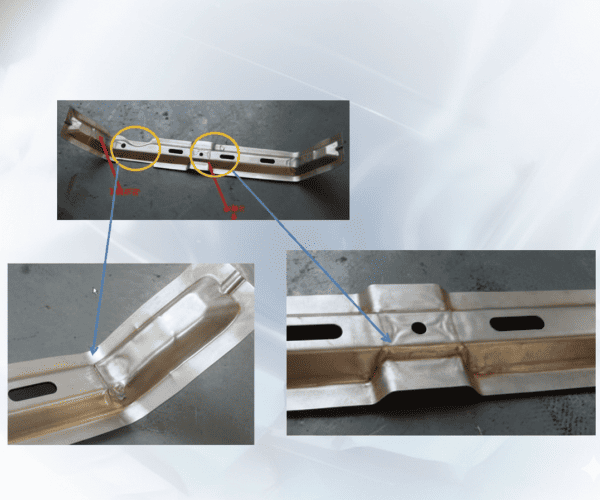

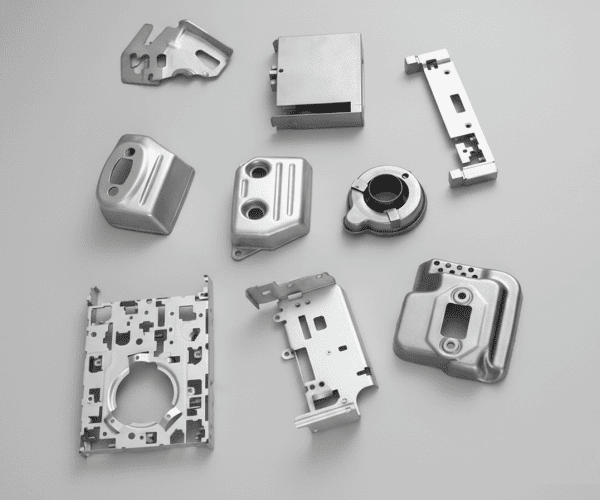

Bending & Flanging Solutions

Our advanced bending and flanging capabilities create precise angular features, reinforced edges, and complex geometries. Essential for structural components and assemblies requiring exact dimensional control.

-

Structural ComponentsBrackets, frames, and reinforcement elements with precise angles

-

Edge ReinforcementFlanged edges for strength, stiffness, and assembly features

-

Complex ProfilesMulti-bend components with tight radius control and minimal distortion

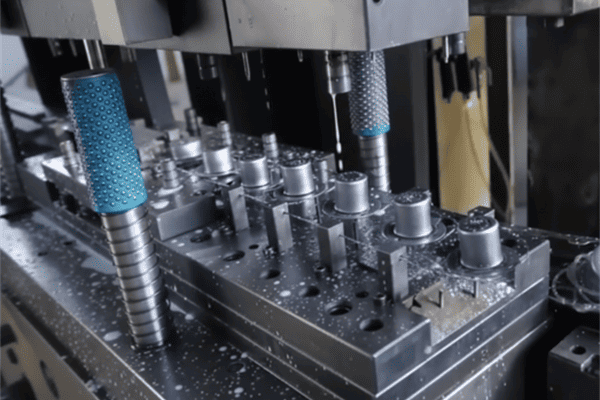

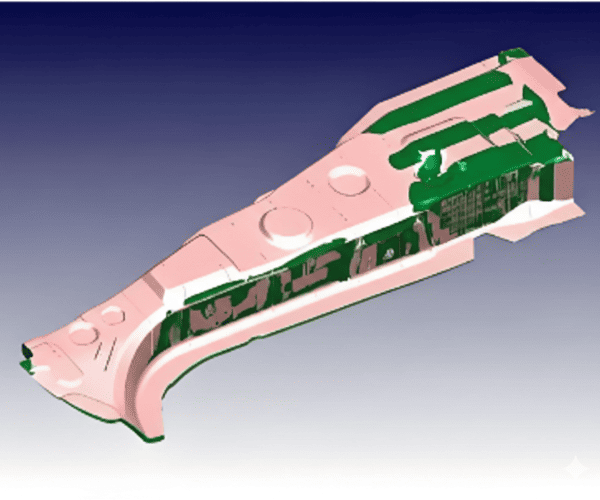

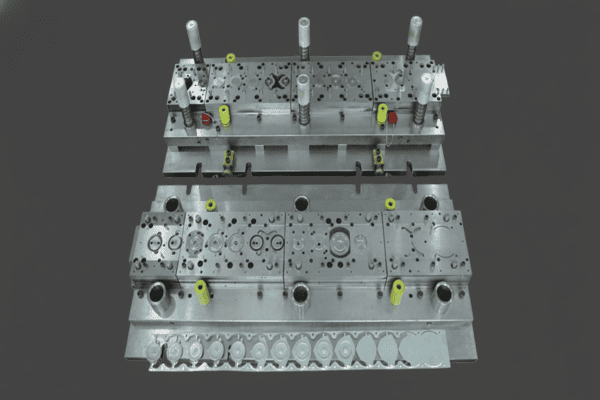

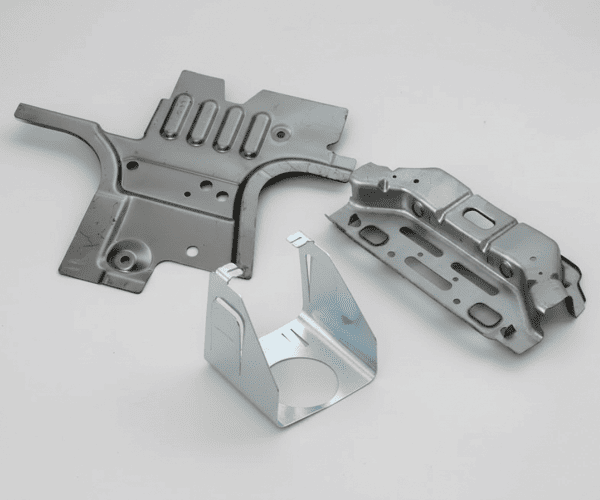

Multi-Stage Forming Expertise

Complex components requiring multiple forming operations are our specialty. Progressive dies and sequential forming processes enable the creation of intricate parts that single-stage operations cannot achieve.

-

Progressive Die OperationsSequential forming, piercing, and trimming in a single press cycle

-

Complex GeometriesDeep draws with flanges, undercuts, and multiple features

-

High Volume ProductionOptimized for mass production with consistent quality and dimensional accuracy

Engineering Focus

Advanced engineering principles and precision tooling for superior part quality.

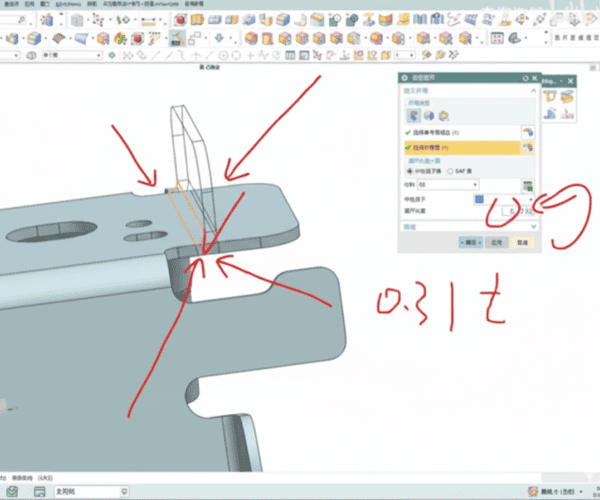

Draw ratio & redraw feasibility check

Calculate optimal draw ratios and evaluate multi-stage forming requirements for complex geometries.

Blank holder force / draw bead strategy

Optimize blank holder pressure and draw bead design to control material flow and prevent wrinkling.

Lubrication & surface protection

Select appropriate lubricants and protective films to minimize friction and surface defects.

Corner radii & material flow optimization

Engineer proper corner radii and material flow paths to achieve uniform wall thickness distribution.

Springback control & compensation

Predict and compensate for material springback through advanced simulation and tooling design.

In-process inspection + final dimensional validation

Implement continuous monitoring and comprehensive dimensional verification for quality assurance.

Design for Manufacturing (DFM)

Our DFM guidelines ensure your parts are optimized for deep drawing processes, reducing costs and improving quality from the design stage.

Wall Thickness

Maintain uniform wall thickness to prevent tearing and ensure consistent material flow during forming operations.

Corner Radii

Adequate corner radii (minimum 4-6x material thickness) prevent stress concentration and cracking.

Draft Angles

Proper draft angles (0.5-2°) facilitate part ejection and reduce tooling wear in deep drawing operations.

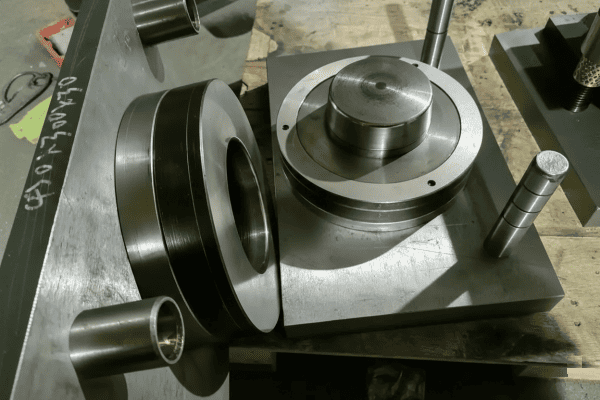

Tooling Options

From prototype tooling to high-volume production dies, we offer flexible tooling solutions tailored to your project requirements and production volumes.

Prototype Tooling

Rapid prototype tooling for design validation and small batch production. Cost-effective solution for testing part feasibility and design optimization.

Production Tooling

High-volume production dies engineered for extended tool life and consistent part quality. Optimized for efficiency and minimal maintenance.

Materials & Secondary Operations

Comprehensive material selection and finishing services to meet your exact specifications, from standard grades to specialized alloys with custom surface treatments.

Material Options

Wide selection of high-quality materials to meet your specific application requirements and performance standards.

Metals

- Carbon Steel

- Stainless Steel

- Aluminum Alloys

- Copper & Brass

Specialty

- Titanium

- Inconel

- Tool Steel

- Spring Steel

Secondary Operations

Complete finishing services and secondary operations to deliver production-ready parts with perfect surface quality.

Machining

- Trimming & Deburring

- Piercing & Slotting

- Tapping & Threading

- Welding & Assembly

Surface Treatments

- Plating & Coating

- Anodizing

- Powder Coating

- Custom Finishes

Transform Your Metal

Components with Precision

From simple cups to complex automotive parts, our deep drawing expertise delivers exceptional quality and cost-effective solutions. Upload your designs and discover what's possible.