From CAD to

Physical Prototype

in Days

Transform your designs into high-precision prototypes with our advanced CNC machining, 3D printing, and rapid tooling services. Perfect for design validation and functional testing.

Prototype Options

Choose the optimal prototyping method for your project requirements. From rapid concept validation to functional testing, we offer comprehensive solutions.

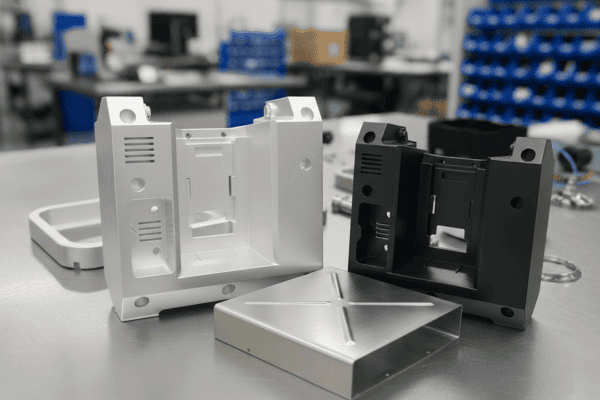

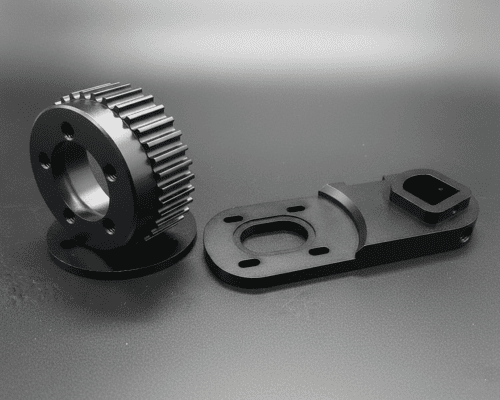

CNC Prototyping

High-precision metal and plastic prototypes machined from production-grade materials. Perfect for functional testing and design validation with ±0.005mm accuracy.

- Aluminum, Steel, Titanium, Engineering Plastics

- 3-5 axis machining capabilities

- 5-12 day turnaround

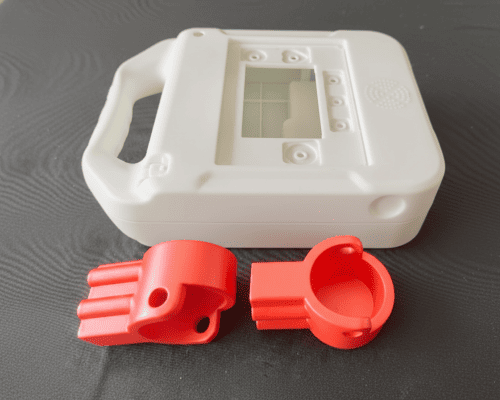

3D Printing

Rapid prototyping with SLA, SLS, and FDM technologies. Ideal for complex geometries and quick design iterations with multiple material options.

- Resin, Nylon, ABS, PLA materials

- Complex internal geometries

- 2-5 day turnaround

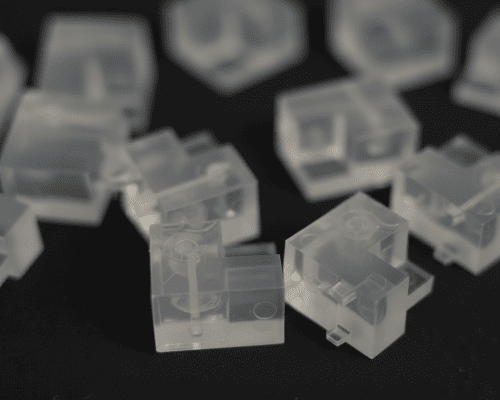

Rapid Tooling

Quick-turn injection mold tooling for low-volume production runs. Bridge the gap between prototyping and full production with aluminum tooling.

- Aluminum mold construction

- 100-10,000 part volumes

- 15-25 day tooling lead time

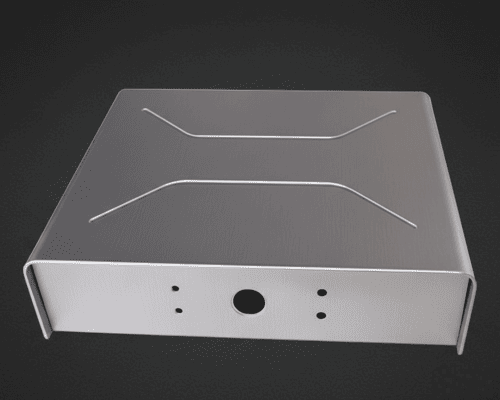

Sheet Metal Prototypes

Laser-cut and formed sheet metal prototypes for enclosures, brackets, and structural components. Complete with welding and finishing services.

- Steel, Stainless Steel, Aluminum

- Laser cutting, bending, welding

- 7-12 day turnaround

Vacuum Molding

Cost-effective thermoforming for large plastic parts and low-volume production. Perfect for housings, covers, and packaging applications.

- ABS, PETG, Acrylic sheets

- Large part capabilities

- 5-8 day turnaround

Technology Selection Matrix

Compare manufacturing methods to find the optimal solution for your project requirements and budget.

| Technology | Delivery Time | Cost Range | Material Range | Precision | Surface Finish | Quantity |

|---|---|---|---|---|---|---|

|

CNC Machining

Precision subtractive manufacturing

|

5-12 Days

Standard lead time

|

$$-$$$

Medium to high

|

Al, Steel, Ti

PEEK, POM

|

±0.005mm

Excellent

|

Ra 0.8-6.3μm

Machined finish

|

1-1000

Low to medium

|

|

3D Printing

Additive manufacturing

|

1-3 Days

Fastest option

|

$-$$

Low to medium

|

Resin, Nylon

ABS, PLA

|

±0.2mm

Good

|

Layer visible

Post-processing

|

1-100

Prototyping

|

|

Vacuum Molding

Silicone mold casting

|

5-10 Days

Mold + parts

|

$$

Medium cost

|

PU resins

Flexible TPU

|

±0.3mm

Fair

|

Smooth

Paintable

|

10-50

Small batch

|

|

Rapid Tooling

Soft tool injection molding

|

2-3 Weeks

Tool + parts

|

$$$

High upfront

|

Production

plastics

|

±0.1mm

Good

|

Injection

molded finish

|

100-1000

Bridge production

|

|

Sheet Metal

Laser cut & formed

|

5-7 Days

Cut & finish

|

$-$$

Low to medium

|

Steel, SS

Aluminum

|

±0.1mm

Good

|

Powder coat

Anodizing

|

1-1000

Very scalable

|

Choose the Right Technology

Design Tips for Fast Prototypes

Optimize your design for rapid manufacturing with these DFM guidelines to reduce lead times and costs.

CNC Machining

Injection Molding

Sheet Metal

Need Detailed DFM Analysis?

Our engineering team provides comprehensive Design for Manufacturing feedback to optimize your designs for cost, quality, and speed.

Get Free DFM ReviewComplete Prototype Deliverables

From initial prototype validation to seamless production transition, we deliver comprehensive documentation and engineering support at every stage.

Prototype Deliverables

Production Transition

Low-Volume Production

Seamless Prototype-to-Production Workflow

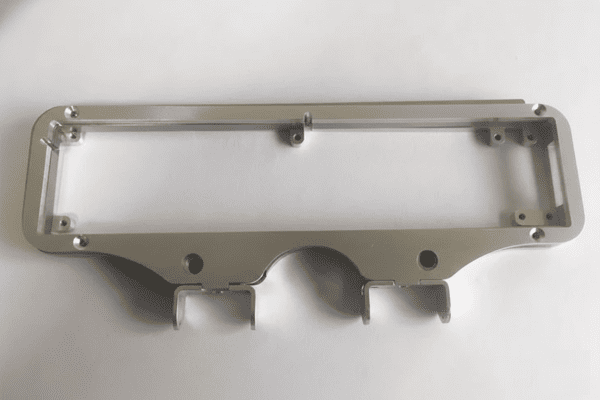

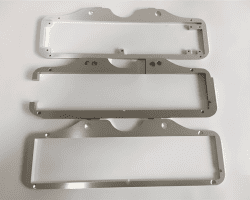

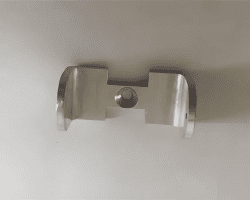

Case Study: Orthodontist Prototypes

How we delivered precision orthodontic components with exceptional speed and quality for a medical device innovator.

Challenge

Medical device startup needed reliable orthodontic prototypes with fast turnaround and competitive pricing.

Solution

- Precision CNC machining with medical-grade tolerances

- Custom bending operations for complex geometries

Results

Delivered 12 precision prototypes in 10 days, enabling rapid development of orthodontic devices.

Prototype Manufacturing FAQs

Get answers to common questions about CNC prototyping, materials, tolerances, and lead times.

Should you choose CNC prototyping or 3D printing?

What tolerances can rapid prototypes typically achieve?

Can prototypes be made in the same material as production?

What are the main factors that affect prototype lead time?

When does rapid tooling make sense for prototyping?

What should you provide to reduce rework and get a "right-first-time" prototype?

Ready to Start Your

Prototype Project?

Upload your CAD files and receive a detailed quote with DFM analysis within 24 hours.