Custom

Precision Parts

From China to World

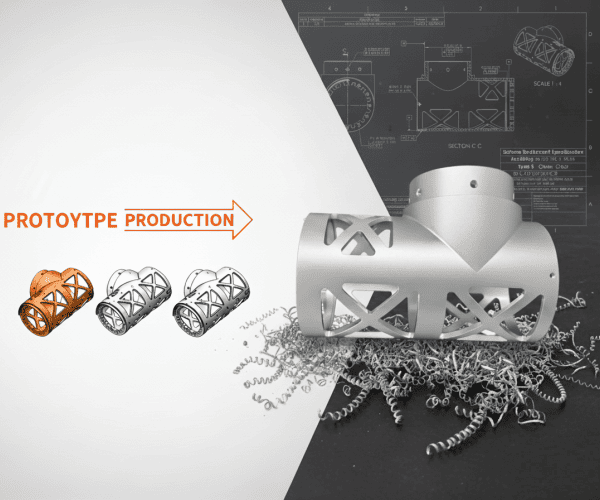

CNC Machining, Injection Molding, Sheet Metal & Stamping. From prototypes to mass production, delivered to 25+ countries with quality assurance.

Complete Production Solutions

Three specialized factories, one commitment: delivering precision parts from prototype to production with global export experience.

CNC Machining

3-5 axis precision milling and turning for complex metal parts with ±0.005mm tolerance.

- Aluminum, Steel, Titanium

- 1-10,000+ units

Injection Molding

Custom mold design and high-volume plastic component production with full DFM support.

- ABS, PC, PP, Nylon

- 500-1M+ units

Sheet Metal

Laser cutting, bending, welding, and assembly for enclosures and structural components.

- Steel, Stainless, Aluminum

- Powder coating, Plating

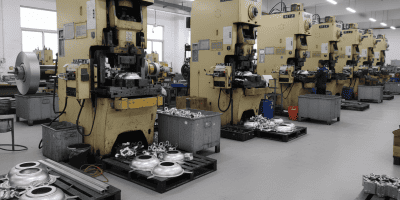

Metal Stamping

Progressive and transfer die stamping for high-volume precision metal components production.

- Custom die design

- 10,000-10M+ units

Comprehensive Resources

for Your Growth

Expert insights and practical solutions for common manufacturing challenges across materials, design, production, and quality control.

Materials

Material selection guides, properties comparison, and compatibility analysis for different manufacturing processes.

Read moreDesign

Design for manufacturing principles, CAD best practices, and engineering optimization techniques.

Read moreManufacturing

Production process insights, troubleshooting common issues, and maximizing manufacturing efficiency.

Read moreOptimization

Cost reduction strategies, lead time optimization, and process improvement methodologies.

Read moreDevelopment

Product development lifecycle, prototyping strategies, and scaling from concept to production.

Read moreQuality Inspection

Quality control methods, inspection techniques, and standards compliance for manufacturing excellence.

Read moreNeed Specific Manufacturing Guidance?

Our engineering team provides personalized DFM analysis and manufacturing recommendations for your specific project requirements.

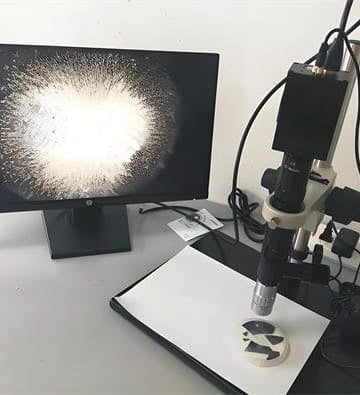

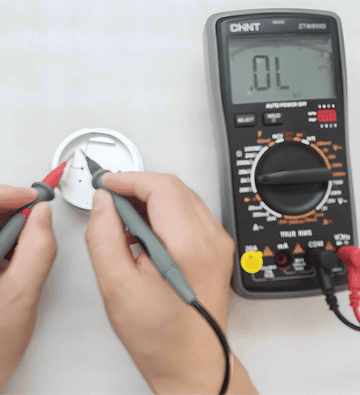

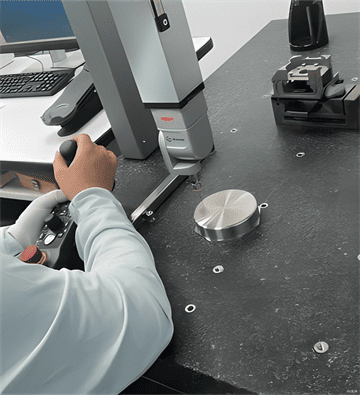

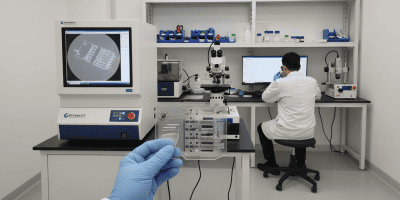

Comprehensive Testing Standards

Every part undergoes rigorous inspection using advanced testing equipment to ensure compliance with international quality standards and customer specifications.

Surface Inspection

Visual and optical inspection for surface defects, scratches, and finish quality

Dimensions Inspection

CMM and precision measurement tools for dimensional accuracy verification

Hardness Testing

Rockwell, Brinell, and Vickers hardness testing for material properties

Roughness Inspection

Surface roughness measurement for texture and finish specifications

Film Thickness Testing

Coating thickness measurement for anodizing, plating, and paint finishes

Insulation Testing

Electrical insulation resistance testing for electronic components

Geometric Tolerances

GD&T verification for form, position, and orientation tolerances

Assembly Testing

Functional testing and fit verification for multi-component assemblies

From Quote to Delivery

Experience our streamlined manufacturing process designed for efficiency, quality, and global reach

Trusted by Industry Leaders

Real projects, real results from our global customers

5-Axis Robotics Components

USA• High-volume production

"Successfully tackled CNC machining of complex aluminum components for robotics, achieving Ra0.6 finish and leak-proof mating surfaces with repeatable accuracy."

Water Heater Components

Argentina • Progressive die

"Revolutionized production with progressive die and in-die tapping, combining multiple operations into one and significantly cutting mold size and production times."

Microfluidic Medical Device

Canada • Rapid prototyping

"Rapid prototyping of microchannel plastic panels with injection molds and etching technology. Successfully crafted experimental molds preparing for mass production."

Three Specialized Factories

Dedicated facilities for each manufacturing process

CNC Machining Center

Injection Molding Plant

Sheet Metal & Stamping

Start Your Manufacturing Project Today

Upload your CAD files and get a detailed quote with DFM analysis within 24 hours